Preparation method for microarray biochip

A biochip and microarray technology, applied in biochemical equipment and methods, enzymology/microbiology devices, biological testing, etc., can solve the problems of low biological preparation efficiency, inability to spot multiple samples at the same time, etc., and achieve low manufacturing costs. , Easy to maintain and use, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

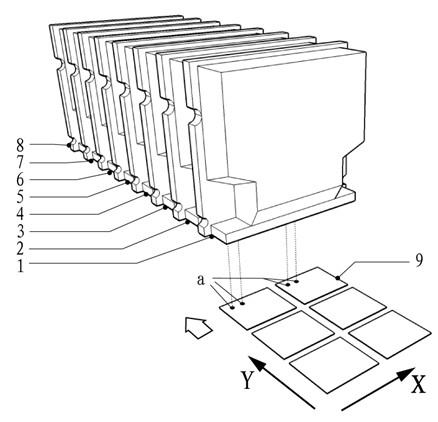

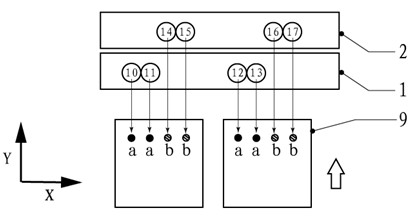

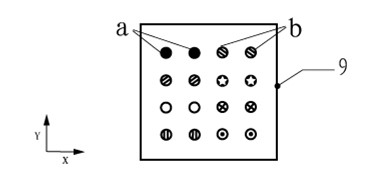

[0025] Such as figure 1 or figure 2 As shown, 1-8 is the nozzle group composed of nozzles, 9 is the biochip substrate, 10-17 are the schematic positions of the working nozzles, a and b are two different index sample points in the typical array structure. The biochip substrate 9 moves along the Y direction. When the predetermined position of the chip substrate 9 moves to the position of the first nozzle 1, the driving signal controls the corresponding nozzle actions at 10, 11 and 12, 13 of the nozzle 1, and the biomolecular solution Sample a is sprayed onto the substrate.

[0026] When the predetermined position of the chip moves to the position of the second spray head 2, the driving signal controls the corresponding nozzles at 14, 15 and 16, 17 of the spray head to spray the biological solution sample b onto the matrix. This completes the first row of spot samples in the X direction. The preparation methods of the other spotting columns are the same, which are completed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com