Etchant composition for a single molybdenum film

A technology of composition and etchant, which is applied in the direction of surface etching composition, chemical instrument and method, etc., can solve the problem of small number of etching layers, and achieve the effects of improving productivity, excellent etching characteristics, and facilitating large-area use

Active Publication Date: 2012-08-22

DONGWOO FINE CHEM CO LTD

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to 3 and comparative example 1

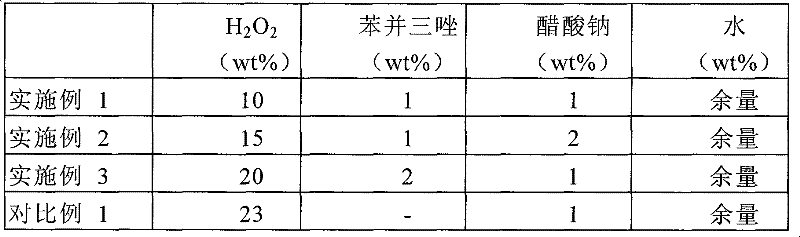

[0025] Examples 1 to 3 and Comparative Example 1: Preparation of etchant composition

[0026] The components and composition ratios of each etchant composition prepared in 180 kg are shown in Table 1 below.

[0027] [Table 1]

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an etchant composition for a single molybdenum film, comprising: 5 to 25 wt % of H2O2; 0.5 to 3 wt % of a cyclic amine compound; 0.5 to 5 wt % of an additive containing one or two or more selected from among a group consisting of sodium dihydrogen citrate, disodium hydrogen citrate, disodium hydrogen phosphate, trisodium citrate and acetate salts; with the remainder being water.

Description

technical field [0001] The invention relates to an etchant composition for a monolayer molybdenum film. [0002] This application claims the benefit of Korean Patent Application No. 10-2009-0110138 filed on Nov. 16, 2009, the entire contents of which are hereby incorporated by reference into this application. Background technique [0003] Semiconductor devices or flat panel displays include TFTs or the like. The TFT includes a gate electrode and source / drain electrodes. Methods of forming these electrodes include metal film formation processes, photolithography processes, and etching processes. This method may further include cleaning processes performed before and after each individual unit process. Here, the metal film formation process is performed by sputtering. In addition, the photolithography process includes the steps of applying a photoresist material on the metal film, exposing and developing selected areas of the photoresist material. Also, the etching proces...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K13/04

CPCC23F1/38

Inventor 林玟基张尚勋慎蕙赢刘仁浩

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com