Mechanical pencil

A technology of mechanical pencils and refills, applied in mechanical pencils, printing, writing utensils, etc., can solve a lot of time and cost problems, and achieve the effect of reducing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

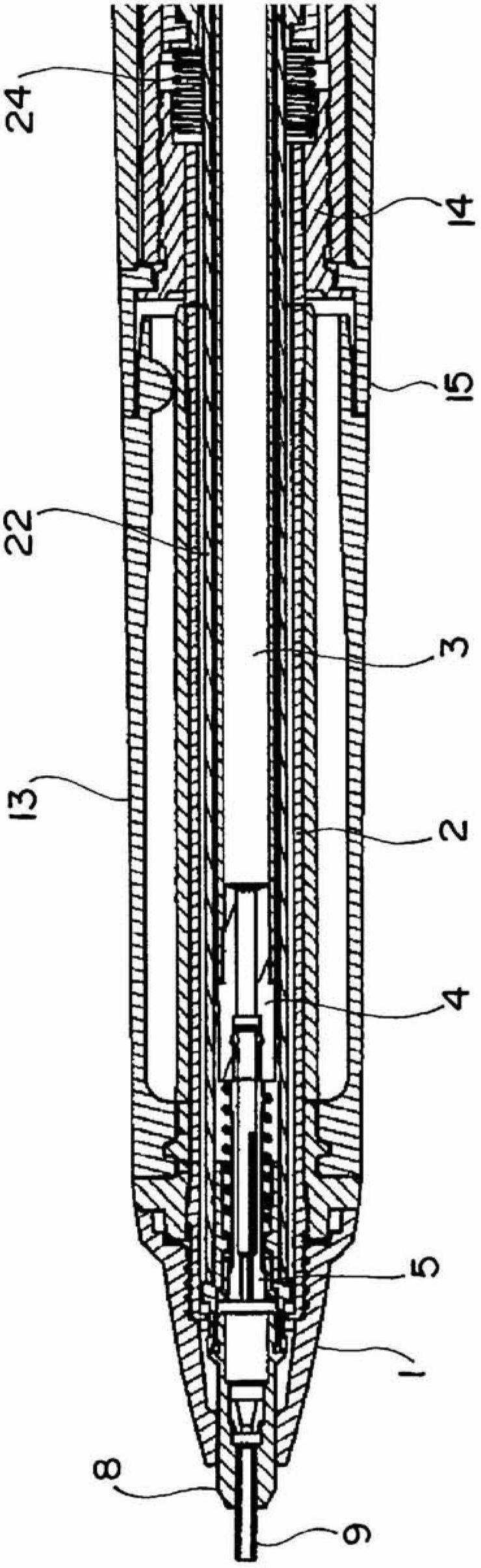

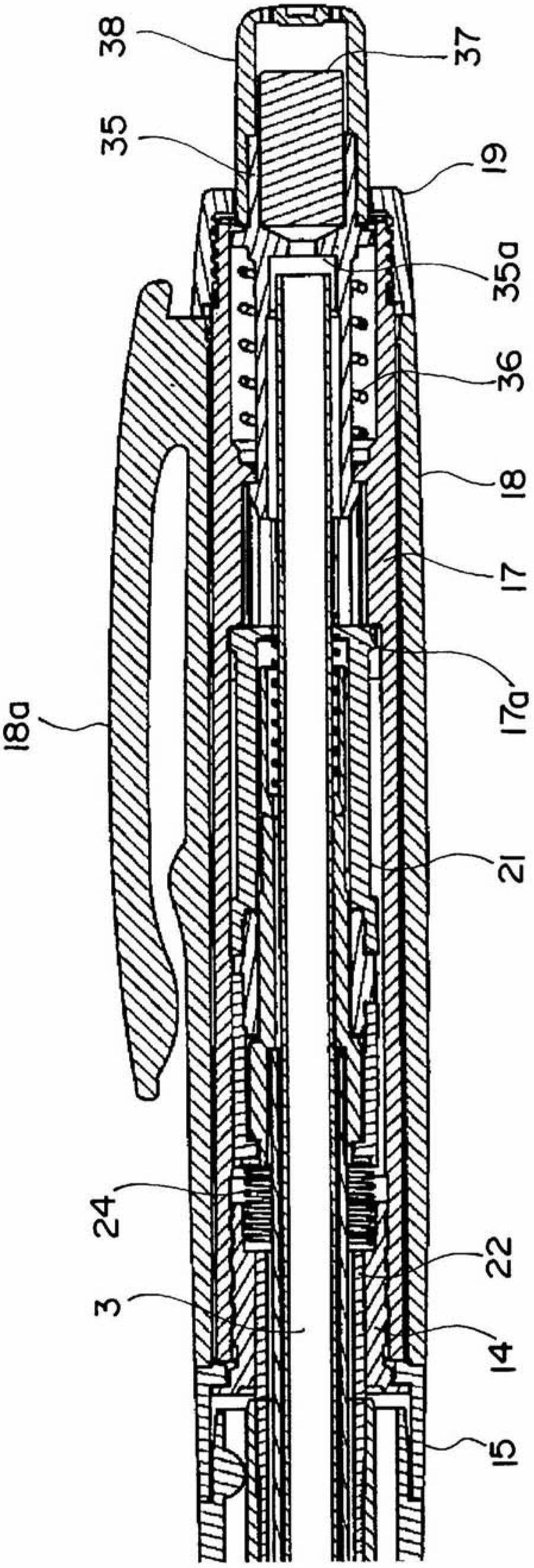

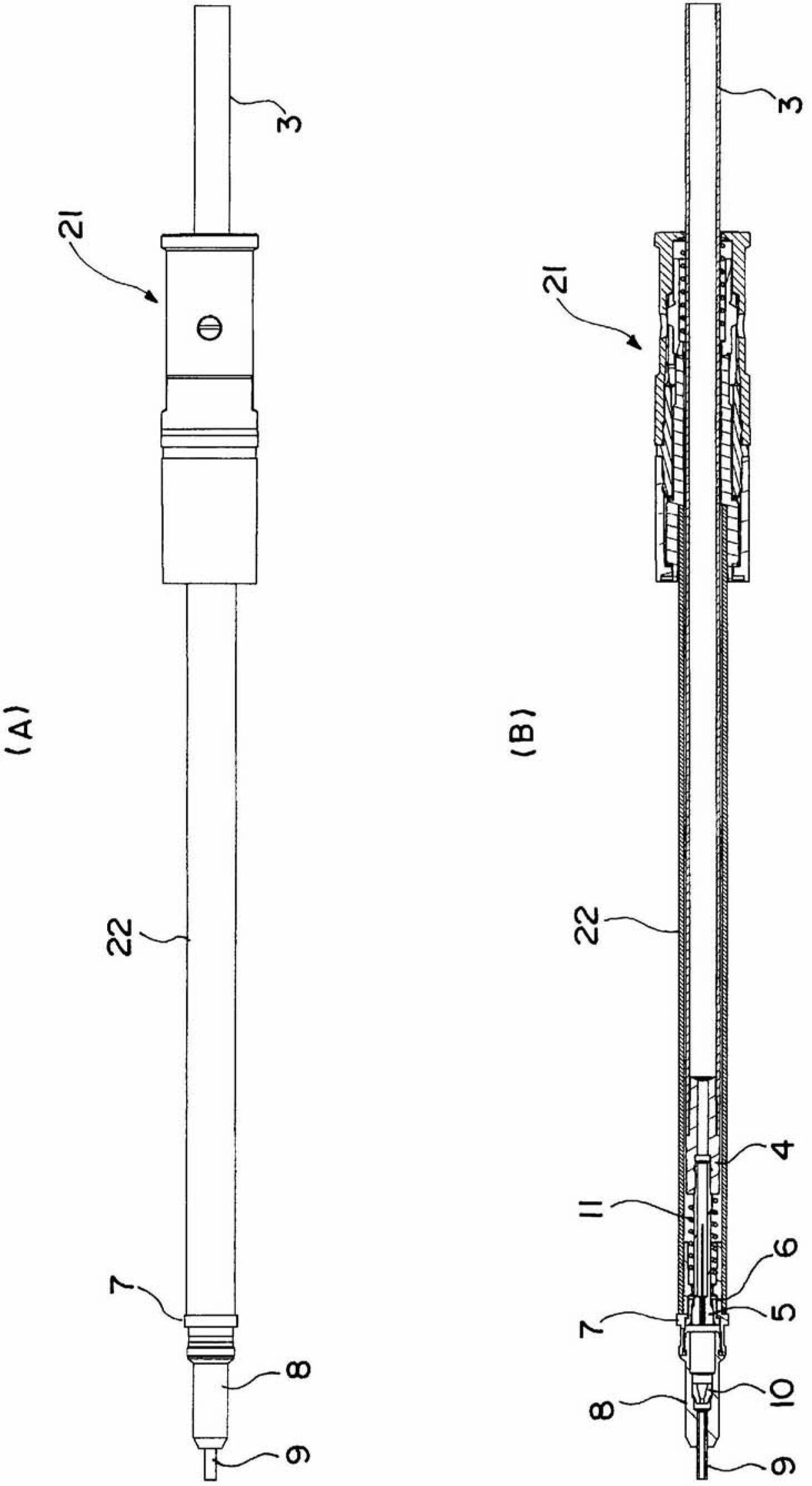

[0046] The mechanical pencil of the present invention will be described based on the illustrated embodiments. figure 1 and figure 2 The overall structure is shown in cross-sectional view, figure 1 Indicates the front half of the mechanical pencil, figure 2 Indicates the second half. In addition, in each figure shown below, the same parts are denoted by the same reference numerals, and in figure 1 and figure 2 In the whole figure shown, the code|symbol is attached|subjected to a representative part.

[0047] An outlet end portion (kuchipura) indicated by reference numeral 1 is detachably attached by screwing to the front end portion of a front shaft 2 constituting a shaft cylinder made of a metal material. Further, a cylindrical core box 3 is housed coaxially along the center portions of the front shaft 2 and a rear shaft described later. At the front end of the core box 3 such as image 3 As shown, a short-axis core box connector 4 is attached, and a brass collet 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com