Solid electrolyte for lead-acid storage battery

A lead-acid battery, solid-state technology, applied in lead-acid batteries and other directions, can solve the problems of poor deep discharge performance, easy leakage of batteries, easy water loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0023] Add 15g of silica powder, 5g of aluminum oxide powder, 40g of tetrafluoroethylene-vinylidene fluoride copolymer, and 500g of acetone solution of dibutyl phthalate (mass concentration: 0.8%) to a mixing chamber In a container, heat to 50°C and stir to form a uniform slurry. The resulting slurry is coated into a film with a coating machine, and the film is washed with methanol to remove dibutyl phthalate and acetone in the film to obtain a modified tetrafluoroethylene-vinylidene fluoride copolymer with a microporous structure membrane. The obtained membrane is then immersed in sulfuric acid, taken out after the adsorption is saturated, and dried in air to obtain a solidified electrolyte, which can absorb 54g of sulfuric acid per 100g of membrane.

Embodiment 3

[0025] Add 5g of silica powder, 25g of aluminum oxide powder, 30g of tetrafluoroethylene-vinylidene fluoride copolymer, and 1000g of dibutyl phthalate in acetone (mass concentration: 1.8%) to a mixer In a container, heat to 50°C and stir to form a uniform slurry. The resulting slurry is coated into a film with a coating machine, and the film is washed with methanol to remove dibutyl phthalate and acetone in the film to obtain a modified tetrafluoroethylene-vinylidene fluoride copolymer with a microporous structure membrane. The obtained membrane is then immersed in sulfuric acid, taken out after the adsorption is saturated, and dried in air to obtain a solidified electrolyte, which can absorb 185g of sulfuric acid per 100g of membrane.

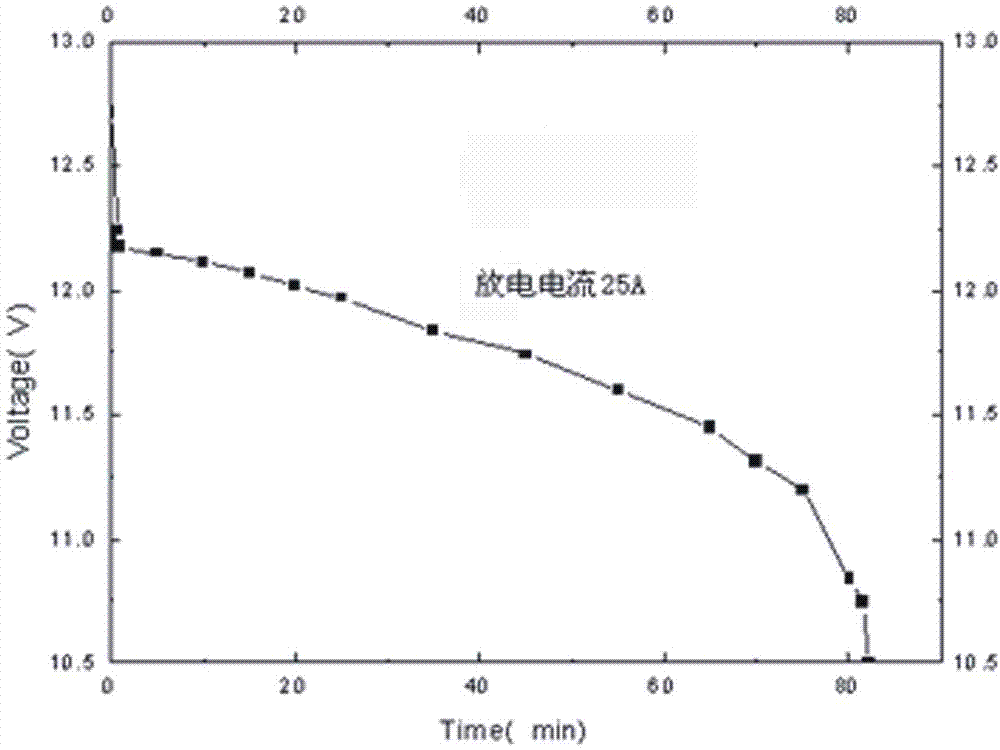

[0026] A 40Ah lead-acid battery (lead dioxide positive electrode / solid electrolyte / sponge negative electrode / solid electrolyte / sponge negative electrode / ..... . / Solidized Electrolyte / Lead Dioxide Cathode). After the battery is deeply discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com