Water-cooling type high-frequency transformer and secondary rectifier

A high-frequency transformer and secondary rectification technology, applied in the direction of transformer/inductor cooling, transformer, fixed transformer, etc., can solve the problems of switching power supply operation efficiency and stability, difficult installation, low space utilization, etc., to achieve Transformer secondary winding and rectifier circuit are compact, with little mutual interference and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

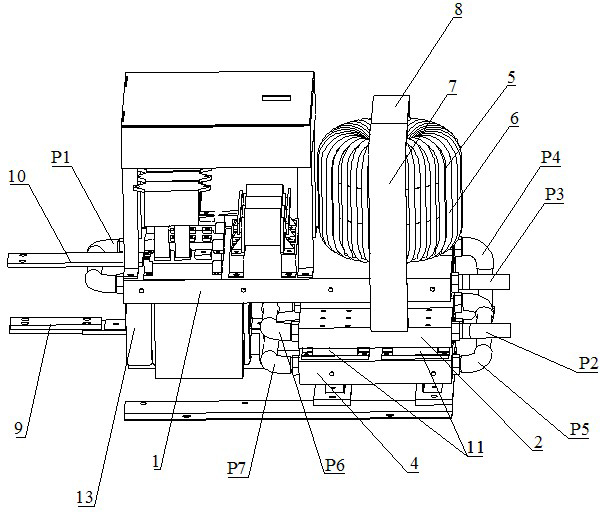

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] like Figure 1~3 As shown, the high-frequency transformer and the secondary rectifier include a first water-cooled heat sink 1, a second water-cooled heat sink 2, a third water-cooled heat sink 3, a fourth water-cooled heat sink 4, a ring magnetic core 5, and a transformer primary winding 6. The first copper bar 7, the second copper bar 8, the first group of common cathode rectifier diode modules 11, and the second group of common cathode rectifier diode modules 12; the first water-cooled heat sink 1 serves as the installation base and power supply of the entire power supply structure The negative pole, the fourth water-cooled heat sink 4 is used as the positive pole of the power supply, the primary winding of the transformer is wound 6 on the ring core 5, the ring core 5 is installed on the first water-cooled heat sink 1, and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com