Visual device for accurately measuring multi-phase thermal conductivity factor at low temperature

A technology for accurate measurement and thermal conductivity, applied in the direction of material thermal development, etc., can solve the problems of double-layer glass tube bursting, uneven temperature of the sample, easy liquefaction of the glass state, etc. Observe the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

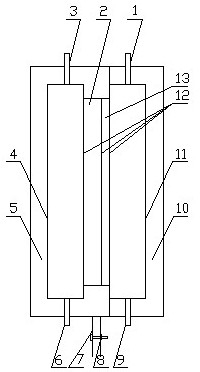

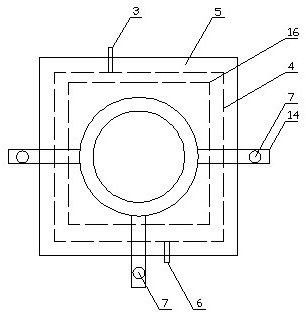

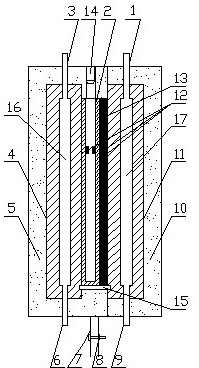

[0015] like Figure 1 to Figure 3 As shown, the visualized device for accurately measuring multi-phase thermal conductivity at low temperature of the present invention includes a quartz box 2, a cold source outlet 3, a cold source copper block 4, a cold source copper block insulation layer 5, an elastic ring 7, a bolt 8, Heat source copper block insulation layer 10, heat source copper block 11, chip thermocouple 12, borosilicate glass 13, camera 14, etc.

[0016] The test bench is composed of a symmetrically arranged cold source copper block 4 and heat source copper block 11 as well as a quartz box 2 and borosilicate glass 13 . The cold source copper block 4 and the heat source copper block 11 are respectively provided with a thin cavity cold source (-120°C) channel 16 and heat source (20°C) channel 17, and a cold source copper block 4 has a cold sourc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com