Preparation method of anticorrosive paint of polyaniline modified mesoporous molecular sieve

A technology of mesoporous molecular sieve and anti-corrosion coating, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve problems such as mechanical properties disadvantage, environmental hazards, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

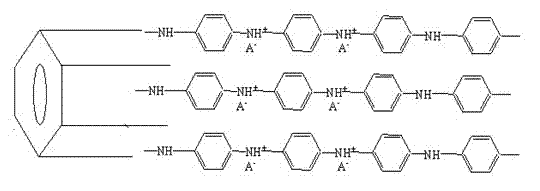

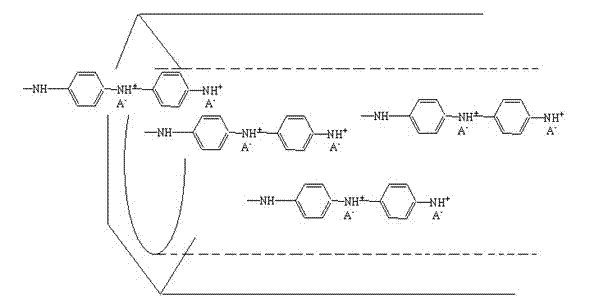

[0050] (1) Preparation of polyaniline-modified mesoporous molecular sieves:

[0051] 1) Add 20 parts of aniline monomer and 50 parts of nanometer mesoporous silica (MCM-41) to 900 parts of 25% acid aqueous solution while stirring at room temperature, and shake in the ultrasonic reactor for 5 Hour;

[0052] 2) Under uniform mechanical stirring, gradually add 20 parts of ferrous sulfate with a mass fraction of 2% and 50 parts of potassium dichromate acidic solution with a concentration of 8% in order, continue to react for 8 hours after adding, filter and wash;

[0053] 3) The obtained product was dried in a vacuum drying oven at 60°C for 24 hours to obtain a mesoporous molecular sieve MCM-41 packing whose surface and channels were covered with intrinsic polyaniline.

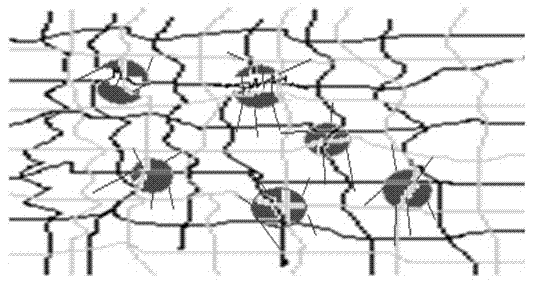

[0054] (2) Preparation of anti-corrosion coating:

[0055] 1) Take 100 parts of water-based epoxy resin and 100 parts of water, add 0.6 parts of ethylene oxide oligomer, 70 parts of dibutyl phthalate, and stir e...

Embodiment 2

[0058] (1) Preparation of polyaniline-modified mesoporous molecular sieves:

[0059] 1) Add 10 parts of aniline monomer and 30 parts of nanometer mesoporous silica (SBA-15) into 500 parts of 25% acid aqueous solution while stirring at room temperature, and shake in an ultrasonic reactor for 3 Hour;

[0060] 2) Under uniform mechanical stirring, gradually add 10 parts of ferrous sulfate with a mass fraction of 2% and 30 parts of ammonium persulfate acidic solution with a concentration of 5% in order, continue to react for 8 hours after adding, filter and wash;

[0061] 3) The obtained product was dried in a vacuum drying oven at 60°C for 24 hours to obtain a mesoporous molecular sieve SBA-15 packing whose surface and channels were covered with intrinsic polyaniline.

[0062] (2) Preparation of anti-corrosion coating:

[0063] 1) Take 150 parts of water-based epoxy resin and 150 parts of water, add 0.3 parts of methyl silicone oil, 60 parts of octyl phthalate, and stir evenly;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com