Method for synthetizing polyaspartic acid by microwaves in ionic liquid

A technology of polyaspartic acid and ionic liquid, which is applied in the field of synthesis of polyaspartic acid, can solve the problems of poor scale inhibition effect, uneven temperature and long reaction time of synthetic products, and achieves improved scale inhibition effect and uniform heating. , the effect of fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

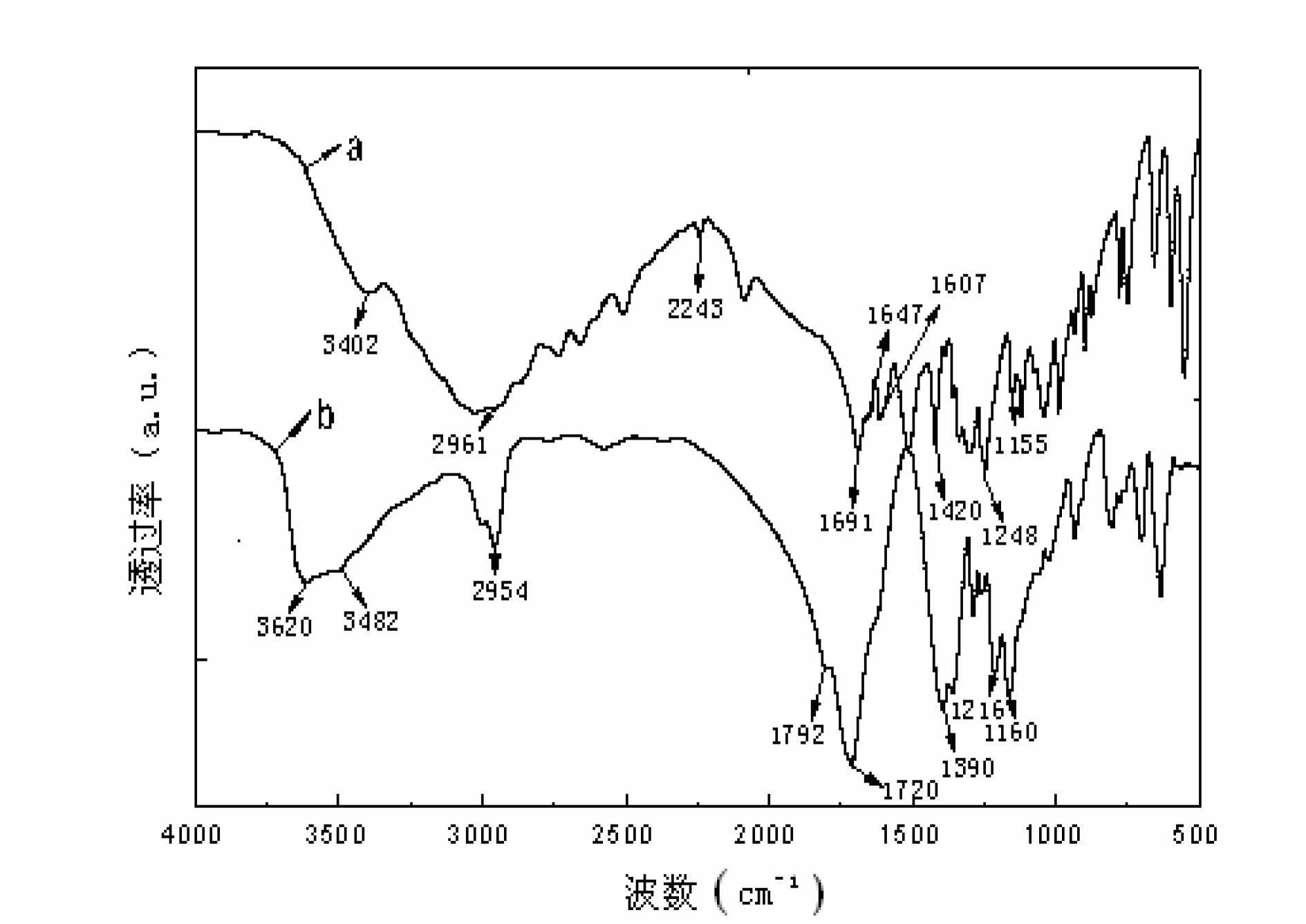

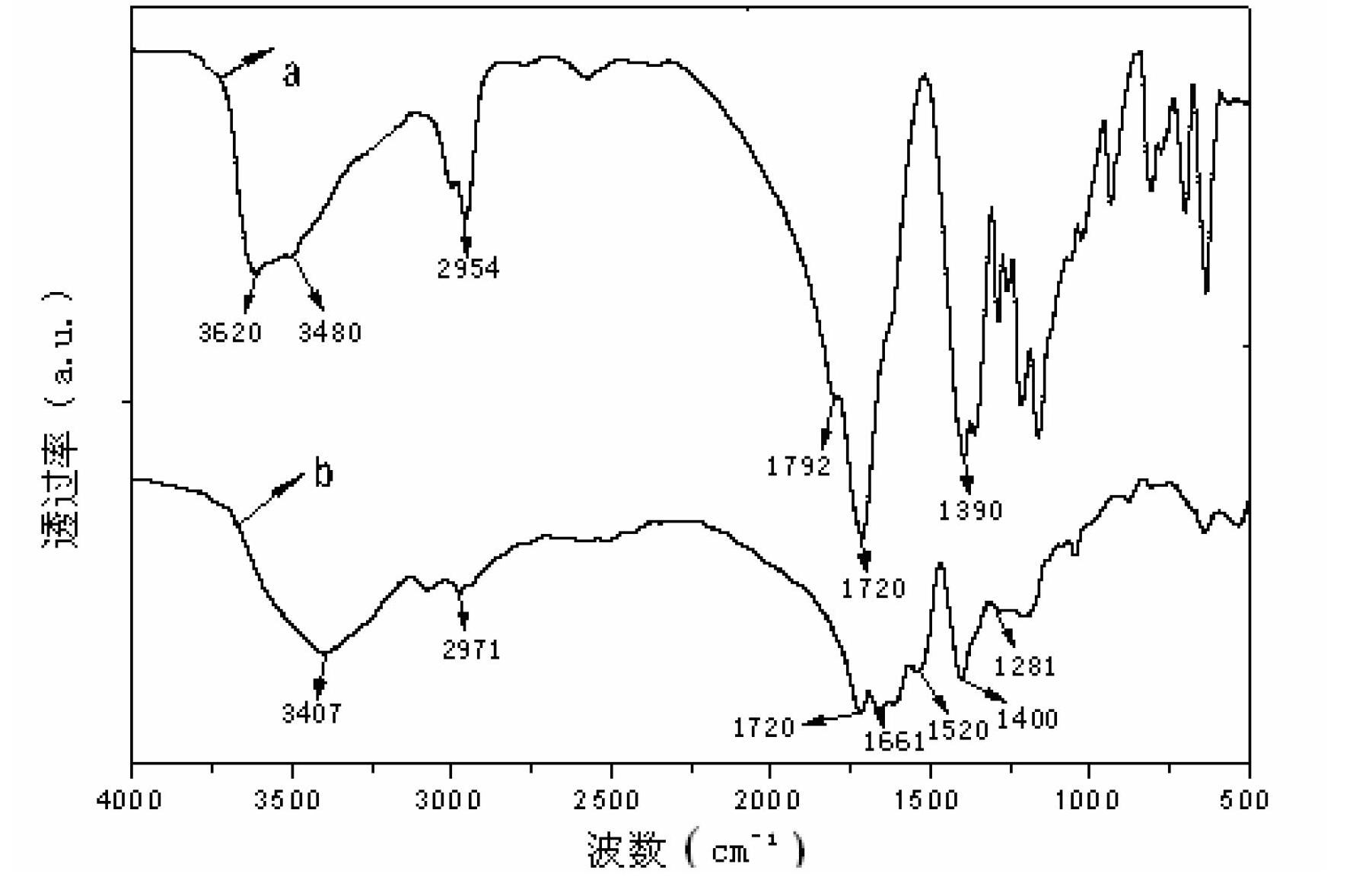

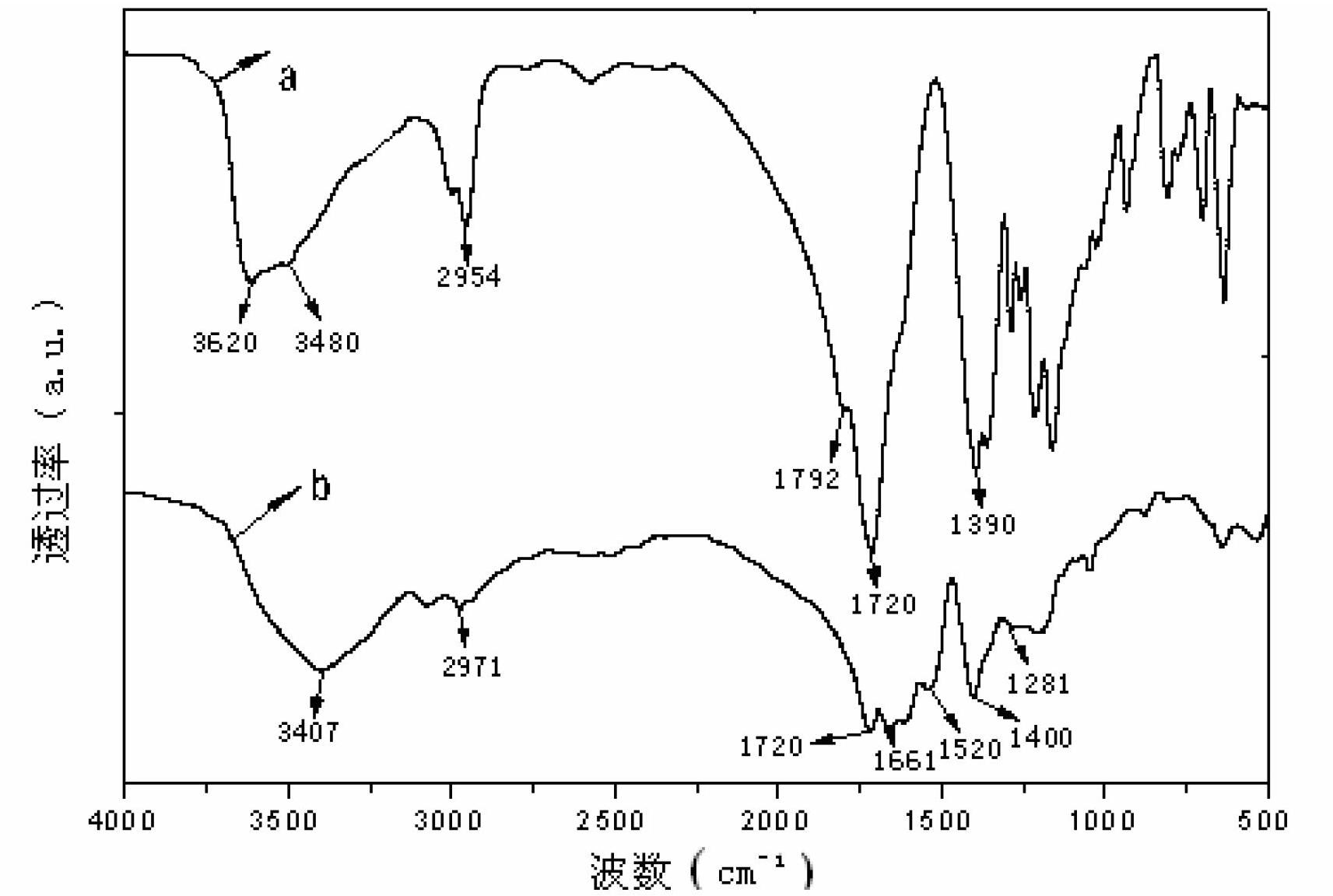

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the method for microwave synthesis of polyaspartic acid in the ionic liquid in the present embodiment is realized through the following steps:

[0020] 1. Weigh N-methylimidazole and sulfuric acid solution respectively according to the ratio of mass volume ratio of 1g: (1.6~2) mL, then add N-methylimidazole into a three-necked flask with a mechanical stirring device and put it in ice Cool in a water bath to 0~5°C, then drop the sulfuric acid solution dropwise into the three-necked flask at a stirring speed of 2000~3000rpm. 2.2h, obtain mixture;

[0021] 2. Distill the mixture obtained in step 1 to remove moisture, the temperature of the vacuum distillation is 70~80°C, and the pressure of the vacuum distillation is 0.1~0.15atm to obtain the ionic liquid [Hmim]HSO 4 ;

[0022] 3. According to the mass ratio (1.0~1.8): 1, weigh L-Asp and [Hmim]HSO obtained in step 2 4 Put it into a beaker and stir evenly, then put the beaker into a microwave ove...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, N-methylimidazole and sulfuric acid solution are weighed according to the ratio of mass volume ratio of 1 g: (1.7~1.9) mL. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, the above-mentioned three-necked bottle is placed in an ice-water bath and cooled to 1~4°C, and the sulfuric acid solution is Drop by drop into the three-neck bottle. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com