Air dielectric energy and pressure storage type reverse osmosis water processor

A technology of water quality treatment machine and compressed air energy storage, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve high water hardness, unstable reverse osmosis working state, etc. problems, to achieve the effect of low wastewater discharge and prolonged effective contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

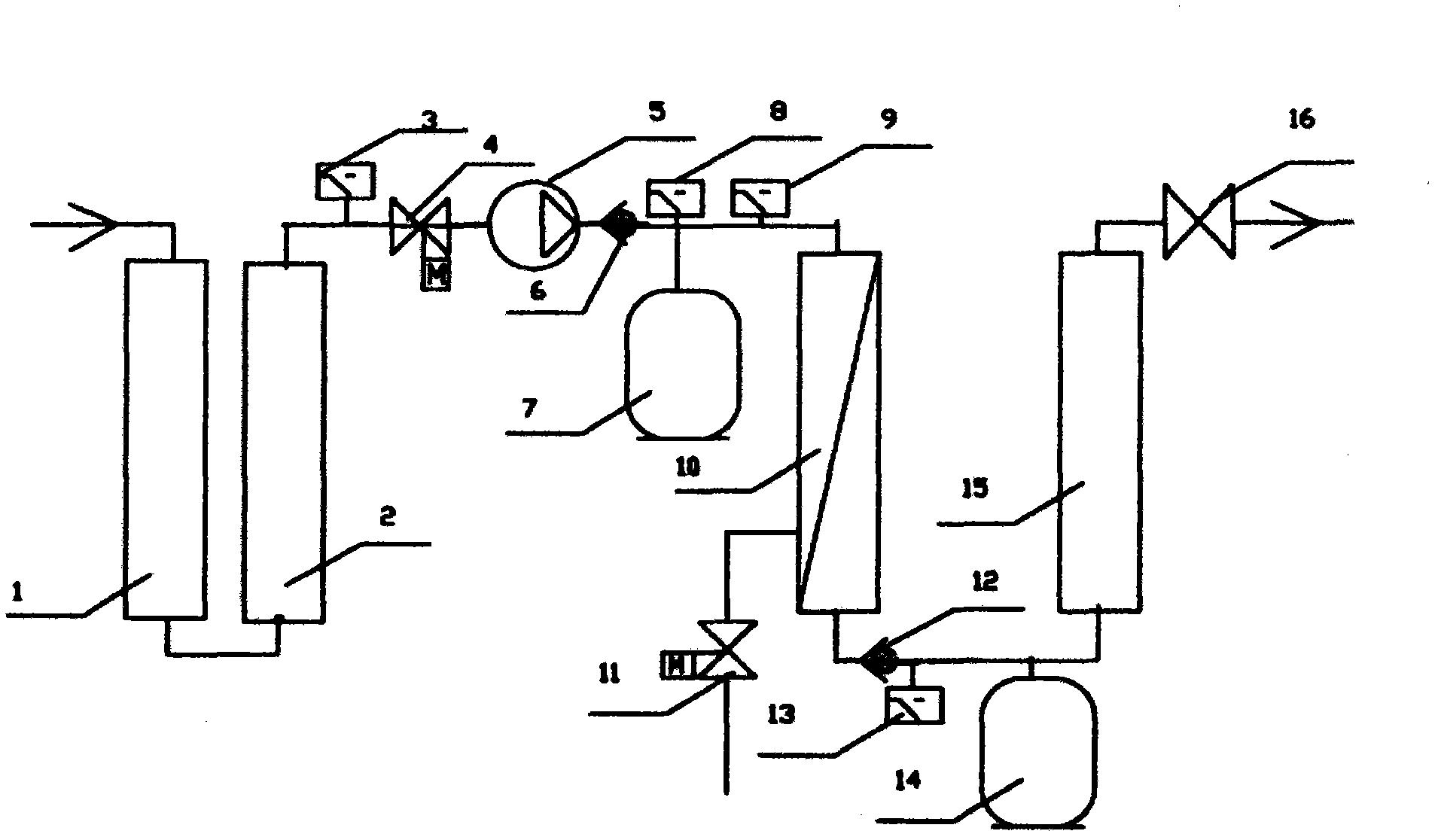

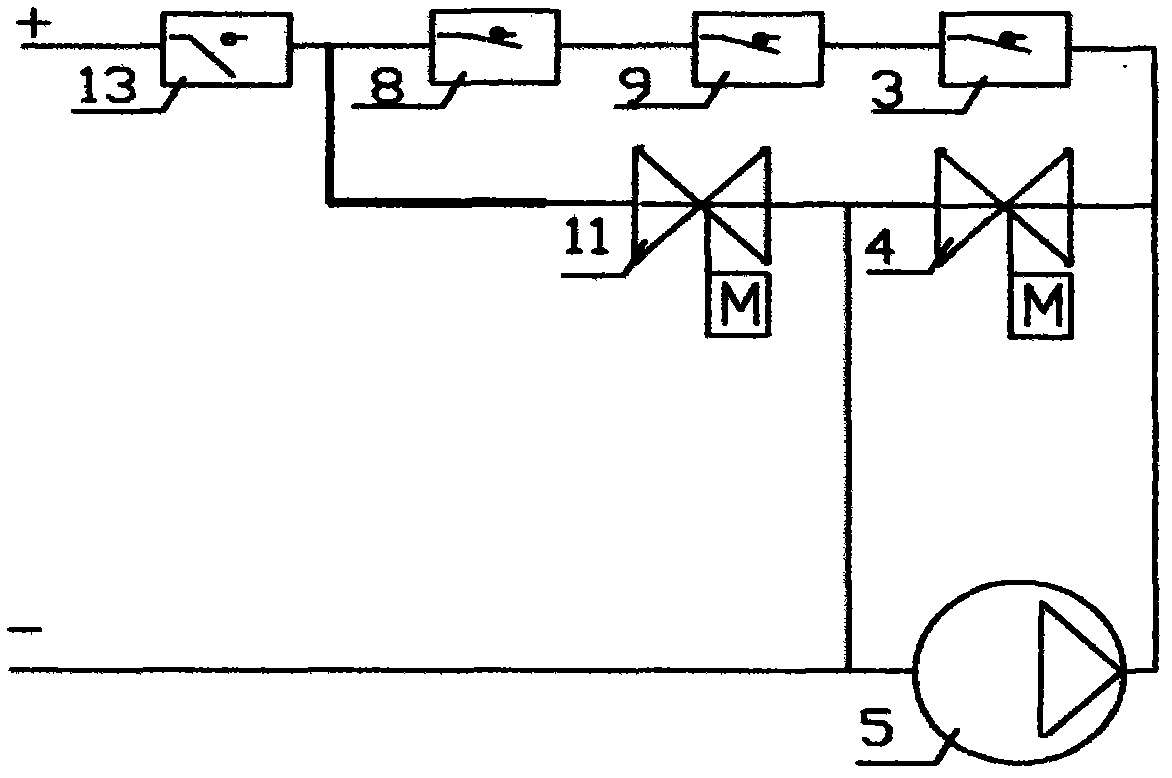

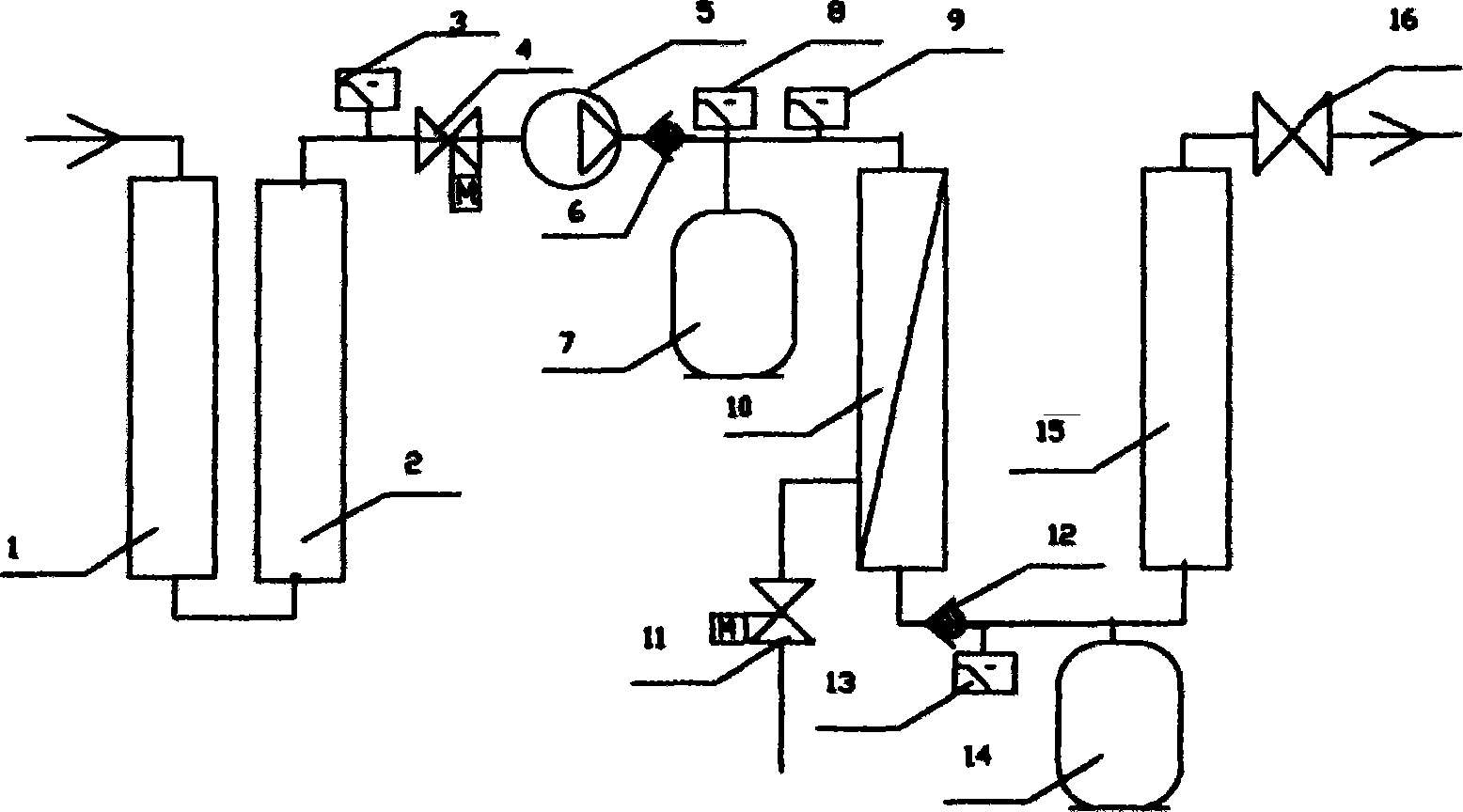

[0020] exist figure 1 Medium, PP cotton (1), activated carbon (2), water inlet solenoid valve (4), booster pump (5), check valve (6), low pressure switch (8), high pressure switch (9), reverse osmosis ( 10), a one-way valve (12), a high-pressure switch (13) with activated carbon (15) behind it, and a water purification faucet (16), which are connected end to end in sequence, wherein the pure water of the reverse osmosis (10) is connected to the one-way valve (12 )front end.

[0021] The front end of the water inlet solenoid valve (4) is connected with an anhydrous protection switch (3) through a tee. Avoid running without water for a long time to damage the machine. It can also be omitted, and this function is replaced by the calculated running time of the high-voltage switch (9), which is more precisely controlled by the circuit.

[0022] A compressed air energy storage tank (7) is installed at the rear end of the one-way valve (6) through a tee. The compressed air energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com