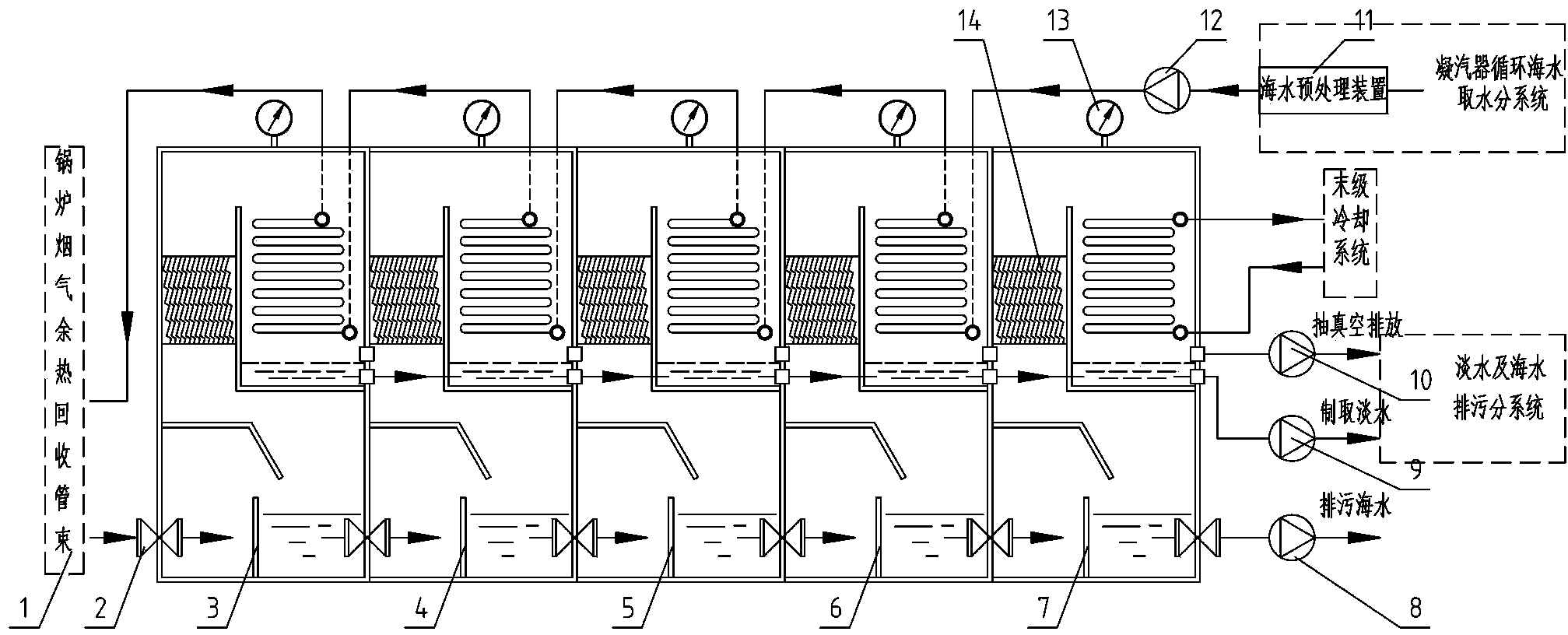

System for desalinating seawater by waste heat from power plant

A seawater system and power plant waste heat technology, which is applied in seawater treatment, heating water/sewage treatment, water/sewage treatment, etc., can solve problems such as low production efficiency, energy waste, and poor performance, and achieve the effect of saving water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

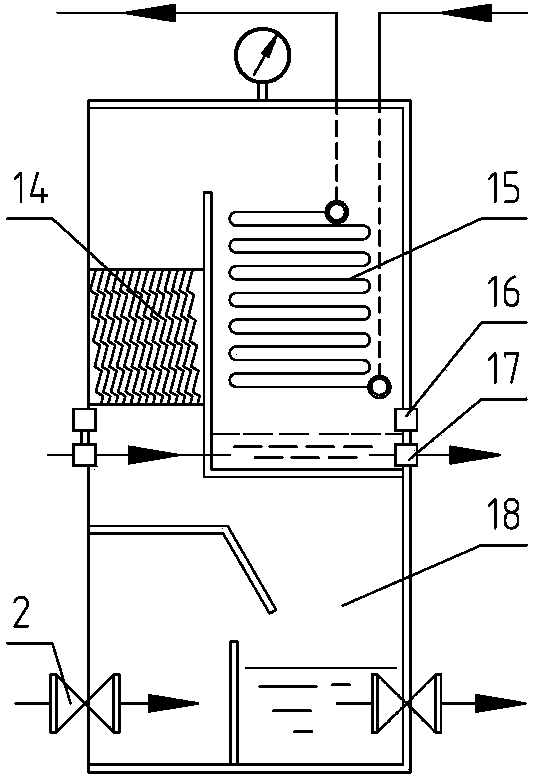

Method used

Image

Examples

Embodiment approach

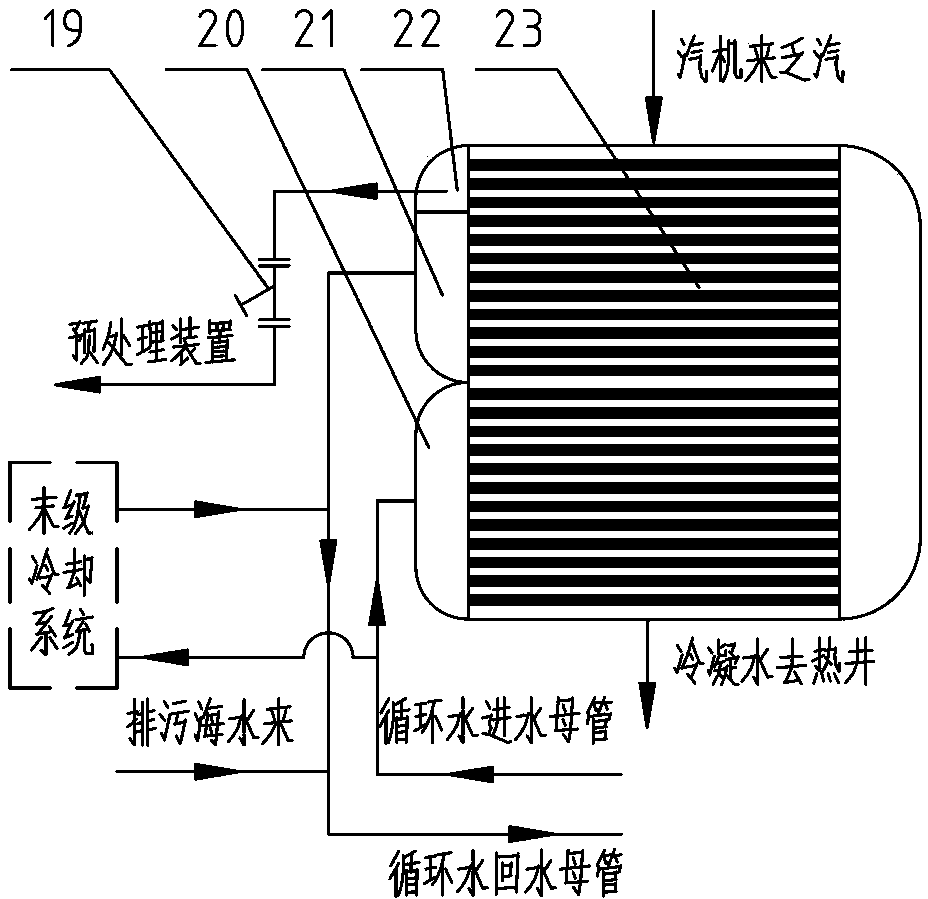

[0048] Such as image 3 As shown, the condenser 23 is composed of a large number of tube bundles. The low-temperature seawater from the jellyfish tubes for circulating water goes inside the tube bundles, and the exhaust steam from the steam turbine goes outside the tubes. When the exhaust steam from the steam turbine passes through the low-temperature tube bundles, it condenses rapidly and releases waste heat , itself turns into condensed water to go to the heat well, and the circulating water from the circulating water into the jelly pipe absorbs the exhaust steam and condenses to release waste heat, and the temperature rises. For general large and medium-sized power plant units, the temperature is generally close to about 40°C. This part The water is directly drained from the circulating water outlet jellyfish pipe, causing a lot of waste; the present invention divides the circulating water of several tube bundles 231 at the top of the condenser through the partition plate 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com