Device and method for steam stripping of condensate in water gas conversion process

A technology of condensate and water gas, applied in the field of coal chemical industry, can solve the problems of air pollution in the venting area, easy to corrode system pipelines, blockage and other problems, and achieve the effect of reducing corrosion, avoiding air pollution and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

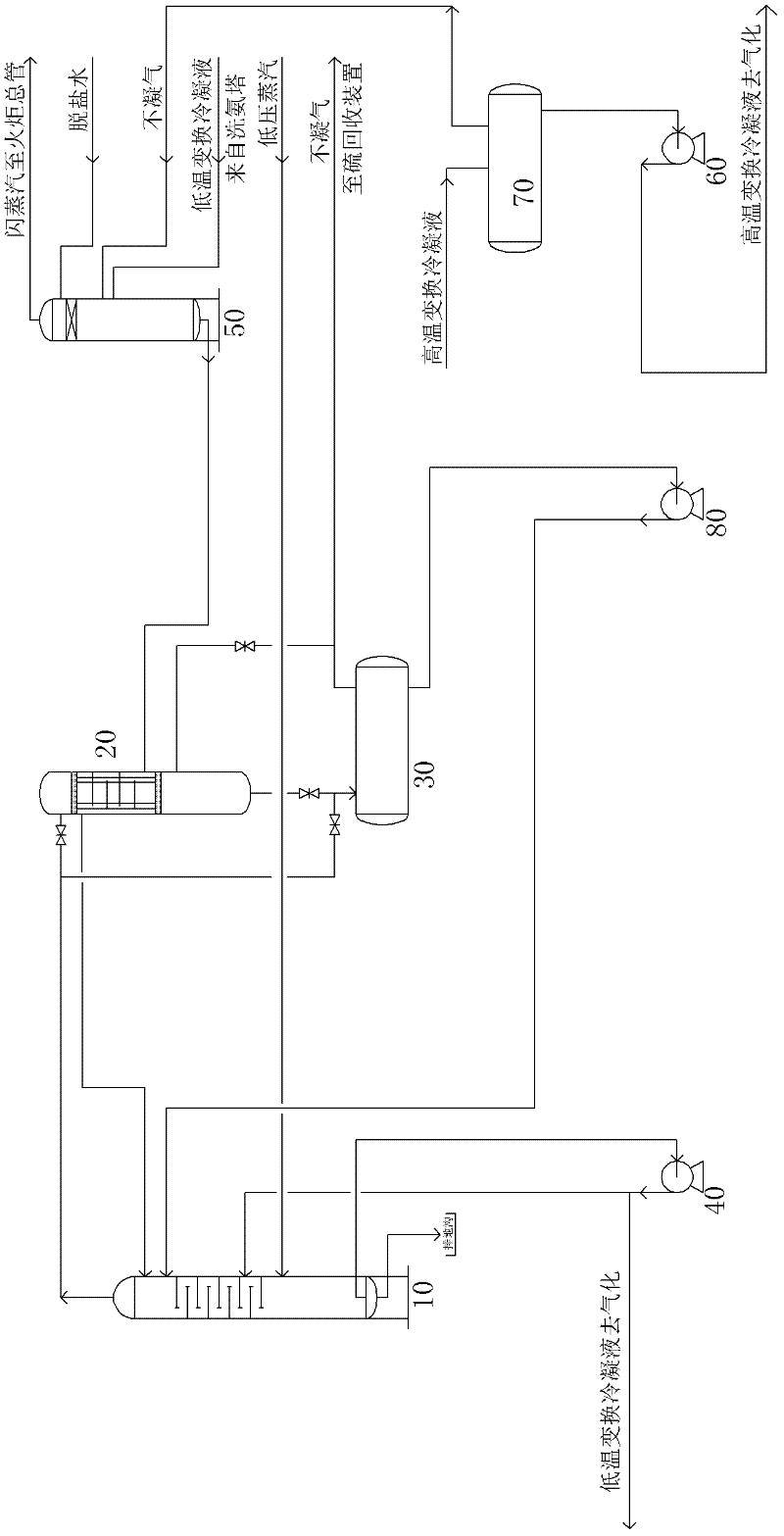

[0027] According to a typical embodiment of the present invention, a method for stripping condensate in a water-gas shift process is provided. The method comprises the following steps: sending the high-temperature condensate separated from the water-gas-water separator into a shift condensate tank for first flash evaporation; The condensed gas is sent to the flash tank together for the second flash evaporation. During the second flash evaporation, the top of the flash tank is sprayed with desalted water to wash and remove the ammonia and hydrogen sulfide in the flash steam, and then the flash steam is sent to the flash steam The treatment device performs treatment; and the condensate after being flashed by the flash tank is sent to the condensate stripping tower for stripping. The condensate flashed by the flash tank enters the condensate stripping tower for stripping after exchanging heat with the stripping gas from the condensate stripping tower through the top condenser of ...

Embodiment 1

[0033] Unlike existing technologies, such as figure 2 Shown, the noncondensable gas that comes from the ammonia washing liquid at the bottom of the ammonia washing tower and the flashing of the conversion condensate tank first enters the flash tank 50, and then enters the condensate stripping tower 10 after flashing (operating condition: 0.35MPa (G ), 136 °C (overhead)) for stripping. Change the non-condensable gas (50.08kmol / hr, H 2 S content 0.137779mol%, NH 3 Content 0.109824mol%, CO 2 content 24.2mol%) and the ammonia washing liquid (8459.415kmol / hr, H 2 S content 0.0070099mol%, NH 3 Content 0.421719mol%, CO 2 content of 0.061mol%) first enters the flash tank 50 for flash evaporation, and the top of the flash tank 50 sprays desalted water to wash and remove ammonia and hydrogen sulfide in the flash steam. 3 The content is low (flash steam: 142.834kmol / hr, H 2 S content 0.2mol%, NH 3 Content 3.2mol%, CO 2 Content 7.5mol%), enter the top of condensate stripper 10 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com