Stabilizer and manufacturing method thereof

A manufacturing method and a technology of a stabilizer, which are applied in earthwork drilling, manufacturing tools, drilling equipment, etc., can solve the problems of uncontrollable thickness consistency of hard alloy wear-resistant layer, reduction of wear-resistant strength of hard alloy powder wear-resistant layer, The production method of the stabilizer is not ideal enough to achieve the effect of simple structure, uniform contact force and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

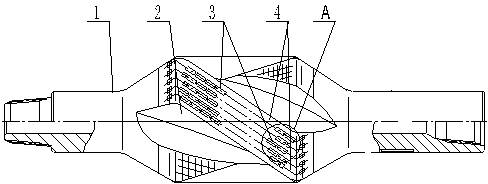

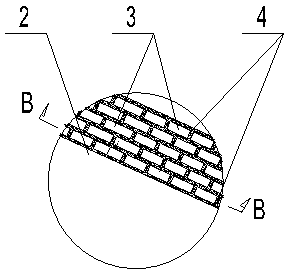

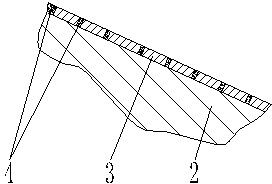

[0017] Embodiment of the present invention: when implementing a manufacturing method of a stabilizer of the present invention, the stabilizer main body 1 is first manufactured according to the existing stabilizer manufacturing process, and the ribbed substrate 2 is made on the stabilizer main body 1 , and then adopt the mode of depositing welding on the ribbed base 2 by the method of the present invention to weld the cemented carbide block 3, this cemented carbide block 3 can directly adopt the product finished product in the prior art; When welding the cemented carbide block 3 on the substrate 2, the cemented carbide block 3 is spot-welded on the ribbed substrate 2 by spot welding first, and then a flame spray gun is used to weld the cemented carbide block 3 on the ribbed substrate 2. Spray wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com