Arsenic removal material by adsorption of electrochemistry strengthened nano ferro-manganese loaded carbon fiberand arsenic removal method by using same

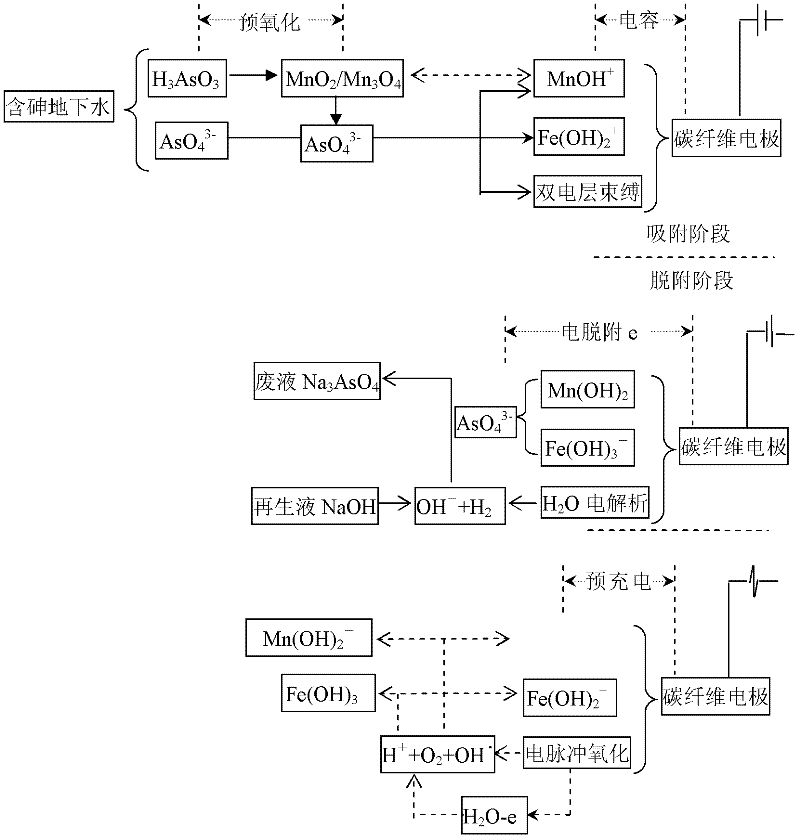

A nano-iron-manganese, electrochemical technology, applied in chemical instruments and methods, inorganic chemistry, separation methods, etc., can solve the problem of low adsorption efficiency of trivalent arsenic, low recyclability of adsorbents, limited adsorption capacity of adsorbents, etc. It can improve the adsorption effect, reduce the dosing of chemical agents for elution, and promote the effect of arsenate desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

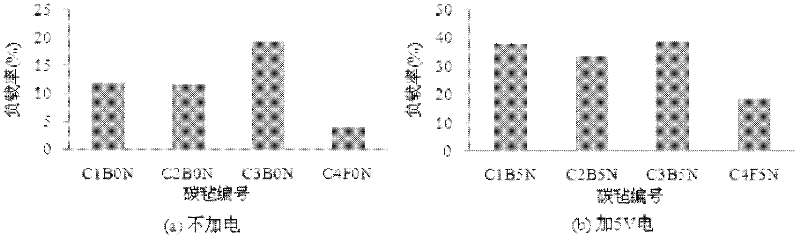

[0032] In order to obtain nanometer-loaded iron-manganese carbon felts under different preparation conditions, an electric field is applied during the preparation, the positive electrode is connected to the reaction solution, the negative electrode is connected to the carbon felt, and the electricity is turned on immediately after adding the carbon felt. Change the voltage (0V, 2V, 5V, 10V) and starch concentration (5g / L, 10g / L, 15g / L, 20g / L, 30g / L), add starch and stir at 120rpm until the reaction solution becomes transparent , after which the KMnO 4 and FeSO 4 ·7H 2 O particles are mixed and ground into fine particles according to a molar ratio of 3:1 and added to the reaction solution. The added weight is 1L of the reaction solution plus 40g. NaOH solution is added to the reaction solution. After the addition, the concentration of sodium hydroxide is 0.1mol / L. Carry out redox reaction in 80°C aqueous solution for 1h, put the carbon felt loaded with iron and manganese into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com