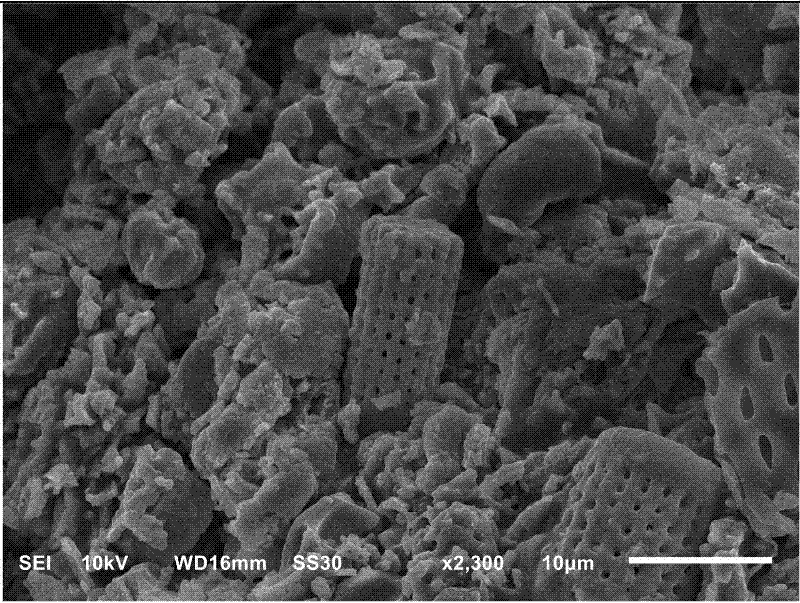

Preparation method for modified kieselguhr composite adsorbing material

A composite adsorption material, diatomite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as low adsorption capacity, inability to effectively remove dyes from printing and dyeing wastewater, and achieve strong adsorption capacity , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) At 25°C, add 1.00g chitosan to 50mL 0.2mol / L ferric chloride solution, stir well until the chitosan is completely dissolved and a sol is formed, then add 2.0g diatom under stirring soil, continue to stir for 2 hours at 25°C;

[0028] 2) Then add 100mL ethanol to obtain a solid precipitate, filter, wash with ethanol, dry and grind into powder;

[0029] 3) At 25°C, add the product obtained in the previous step into the ethanol solution of glutaraldehyde (the concentration of glutaraldehyde is 3vol%), keep stirring for 4 hours to cause cross-linking reaction, filter, wash with ethanol, and dry The desired modified diatomite composite adsorbent is obtained, and the material can be used for dye adsorption.

Embodiment 2

[0031] 1) At 25°C, add 1.00g of chitosan to 50mL of 0.22mol / L ferric chloride solution and stir well until the chitosan is completely dissolved and a sol is formed, then add 0.5g of diatomaceous earth under stirring , continue to stir for 2h at 25°C;

[0032] 2) Then add 120mL ethanol to obtain a solid precipitate, filter, wash with ethanol, dry and grind into powder;

[0033] 3) At 25°C, add the product obtained in the previous step into an ethanol solution of glutaraldehyde (the concentration of glutaraldehyde is 7vol%), keep stirring for 4 hours to cause a cross-linking reaction, filter, wash with ethanol, and dry The desired modified diatomite composite adsorbent is obtained, and the material can be used for dye adsorption.

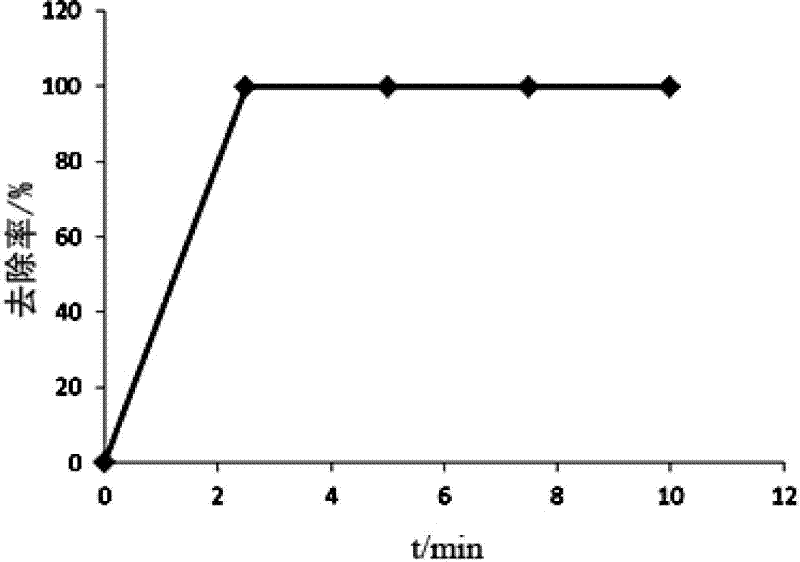

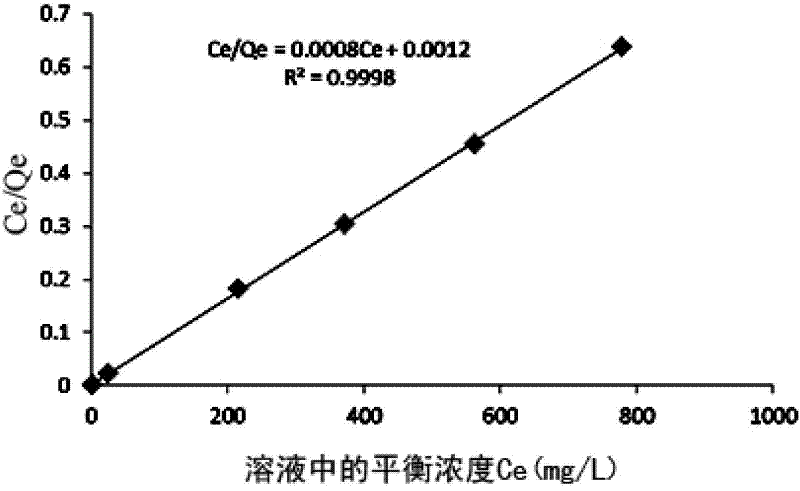

[0034] The application effect of the modified diatomite composite adsorption material prepared by the present invention is illustrated below in conjunction with specific application examples:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com