Multiple-component lateral line thermal coupling rectification method

A process method and thermal coupling technology, applied in fractionation, chemical industry, distillation purification/separation, etc., can solve the problems of few practical applications and difficult to solve practical control problems, and achieve the effect of reducing energy consumption of rectification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

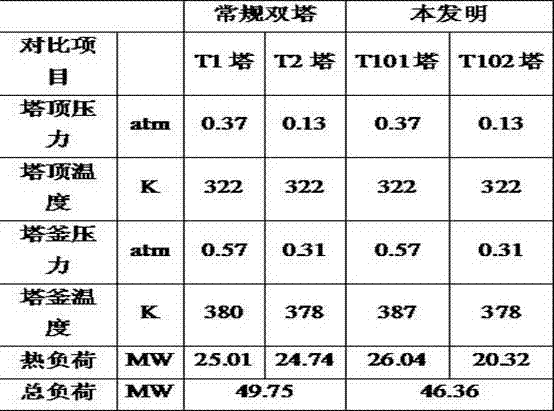

[0014] The present invention includes forward sequence rectification and reverse sequence rectification process, as shown in Fig. 1, in described forward sequence rectification process, multiple component enters first rectification tower T101 as raw material, in the first rectification tower Light components are distilled from the top of T101, and the liquid phase mixture other than light components of the bottom distillate is used as the feed stream of the second rectification tower T102, and the light components are extracted from the side line of the first rectification tower T101 The mixture of points, as the newly added feed stream of the second rectifying tower T102 tower, its feed position is located above the original feed position; in the reverse sequence rectification process, the multicomponent enters the first Rectification tower T101, heavy components are distilled from the bottom of the first rectification tower T101, and the liquid phase mixture other than heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com