Probe measuring device

A measuring device and stylus technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of poor measurement accuracy, wear of contact surfaces, gaps, etc., to ensure the straightness of movement and prevent partial wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

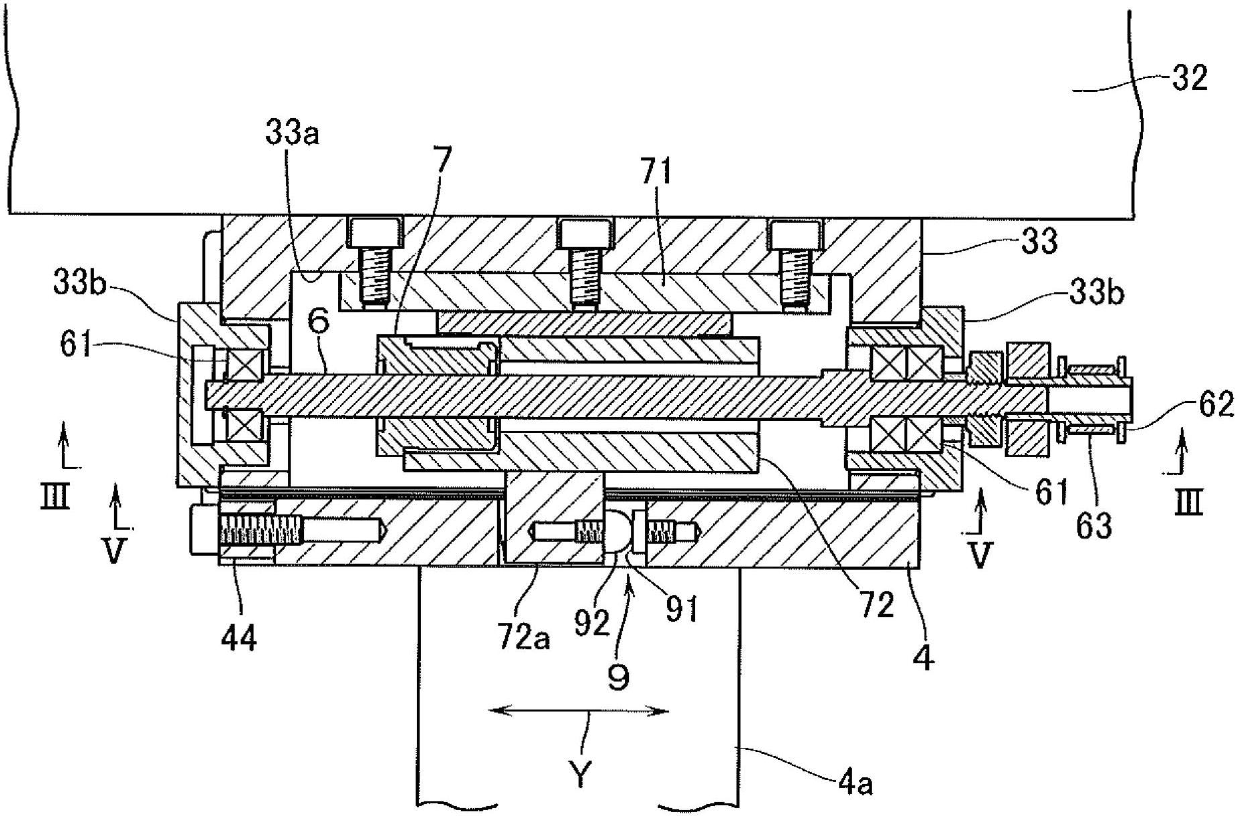

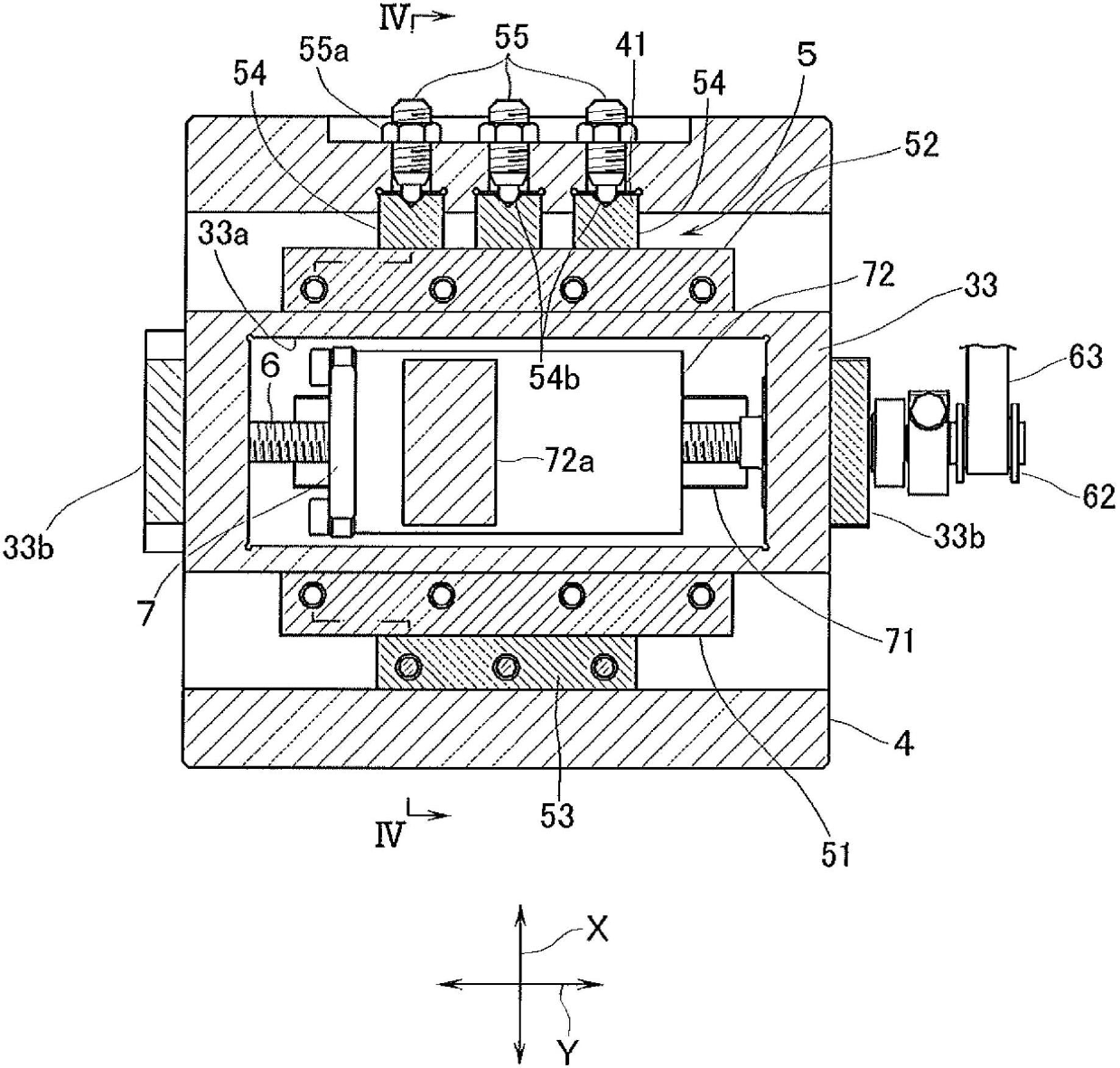

[0022] figure 1 A stylus type measuring device according to an embodiment of the present invention is shown. This measuring device has: a base 1; a sample table 2 for placing a test object W placed on the base 1; and a door-shaped frame 3 arranged on the base 1 so as to straddle the sample table 2 . When two horizontal directions perpendicular to each other are defined as the X-axis direction and the Y-axis direction, the sample stage 2 is movably supported on a pair of guide rails 2a, 2a whose longitudinal direction is in the X-axis direction and fixed on the base 1. . And, the rotation of the ball screw in the X-axis direction in the longitudinal direction, not shown, is used to move the sample table 2 in the X-axis direction through the nut screwed on the ball screw, so that the door-shaped frame 3 is relatively The measured object W moves relatively in the X-axis direction.

[0023] The door-shaped frame body 3 has pillars 31 and 31 erected on both sides of the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com