Thermal management system for automotive batteries

A battery thermal management and vehicle technology, applied in the field of thermal management systems, can solve problems such as battery short circuit, shortened life, battery cell failure, etc., and achieve the effects of achieving thermal insulation performance, improving service life, and large thermal contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

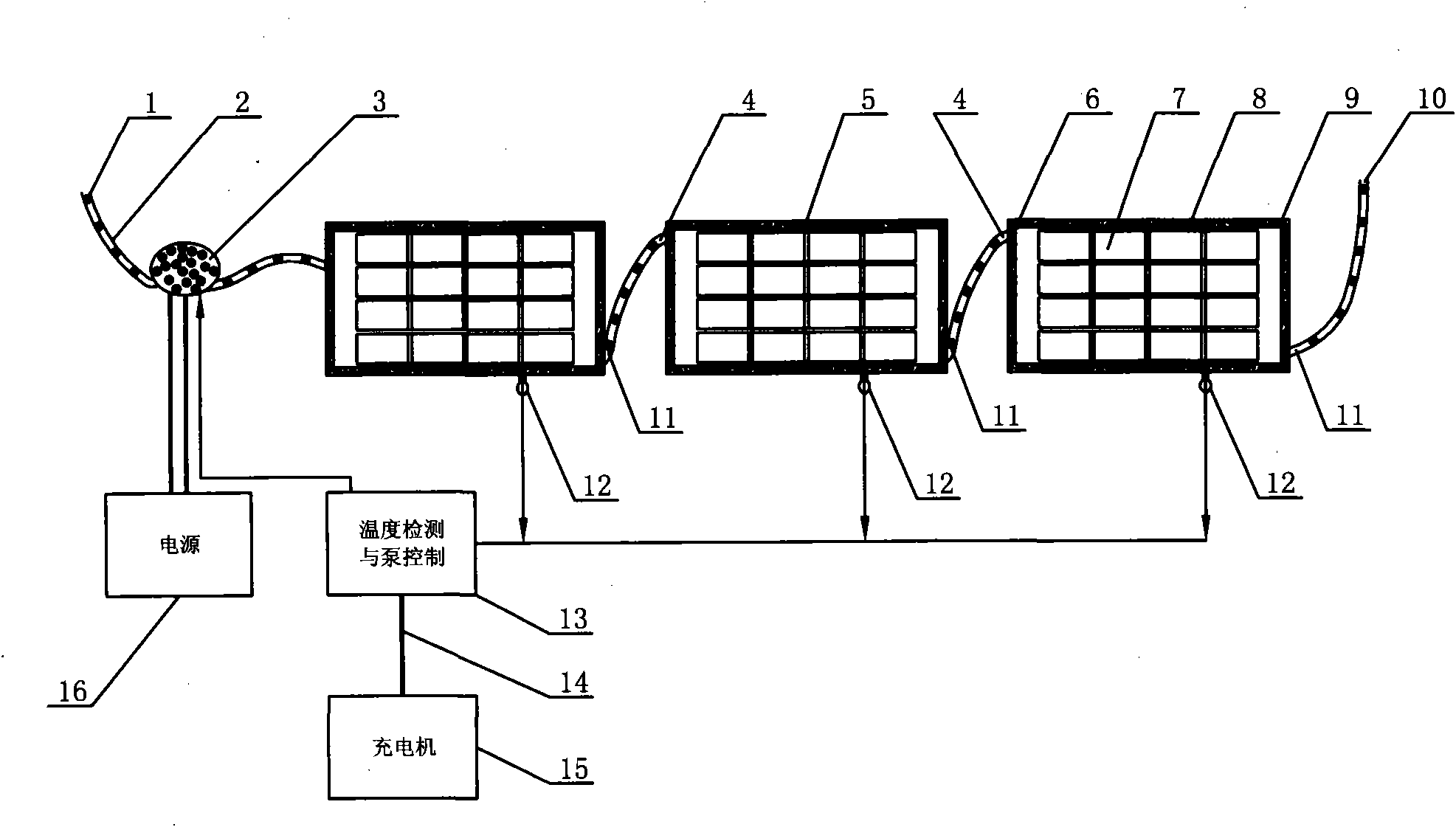

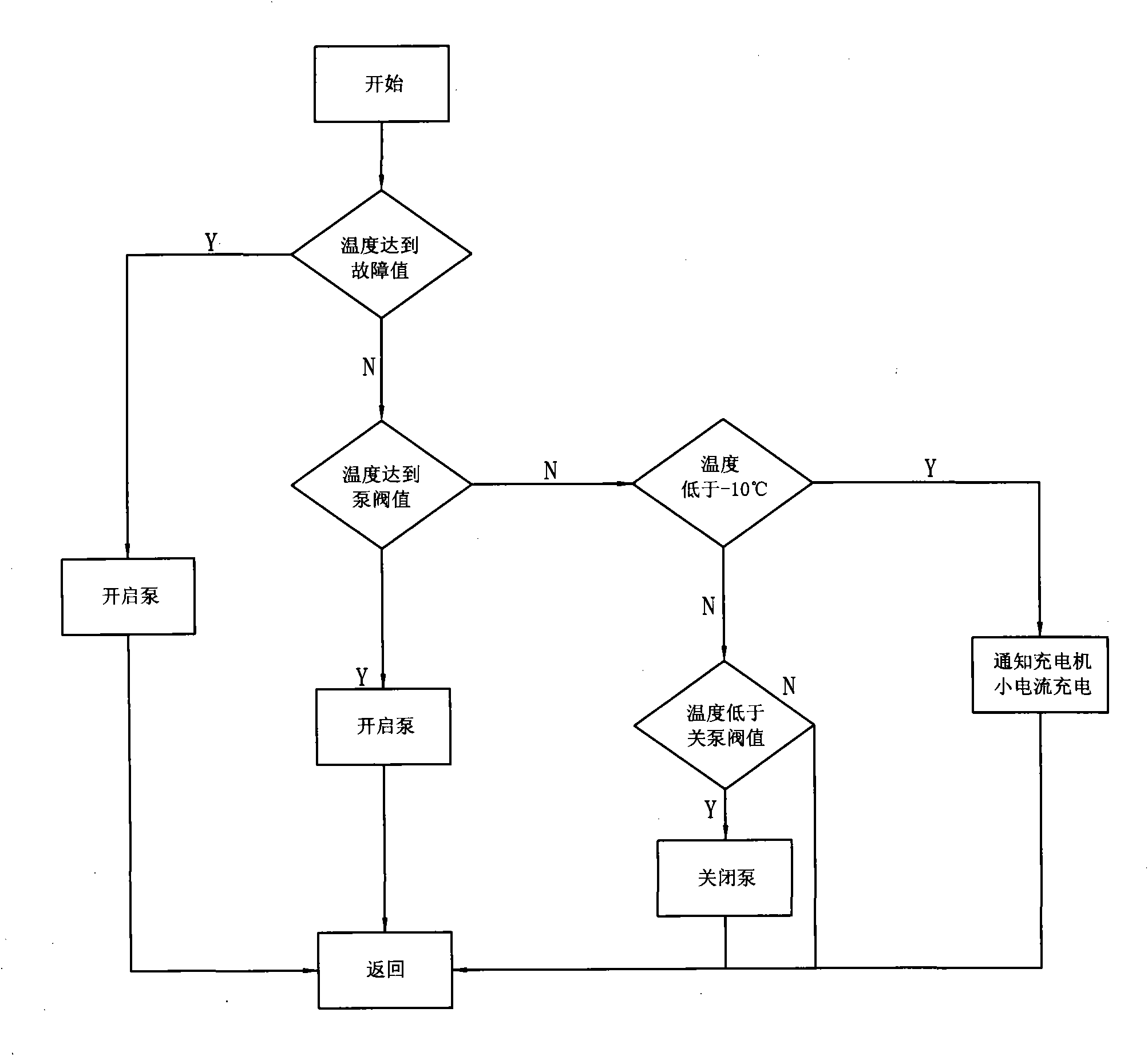

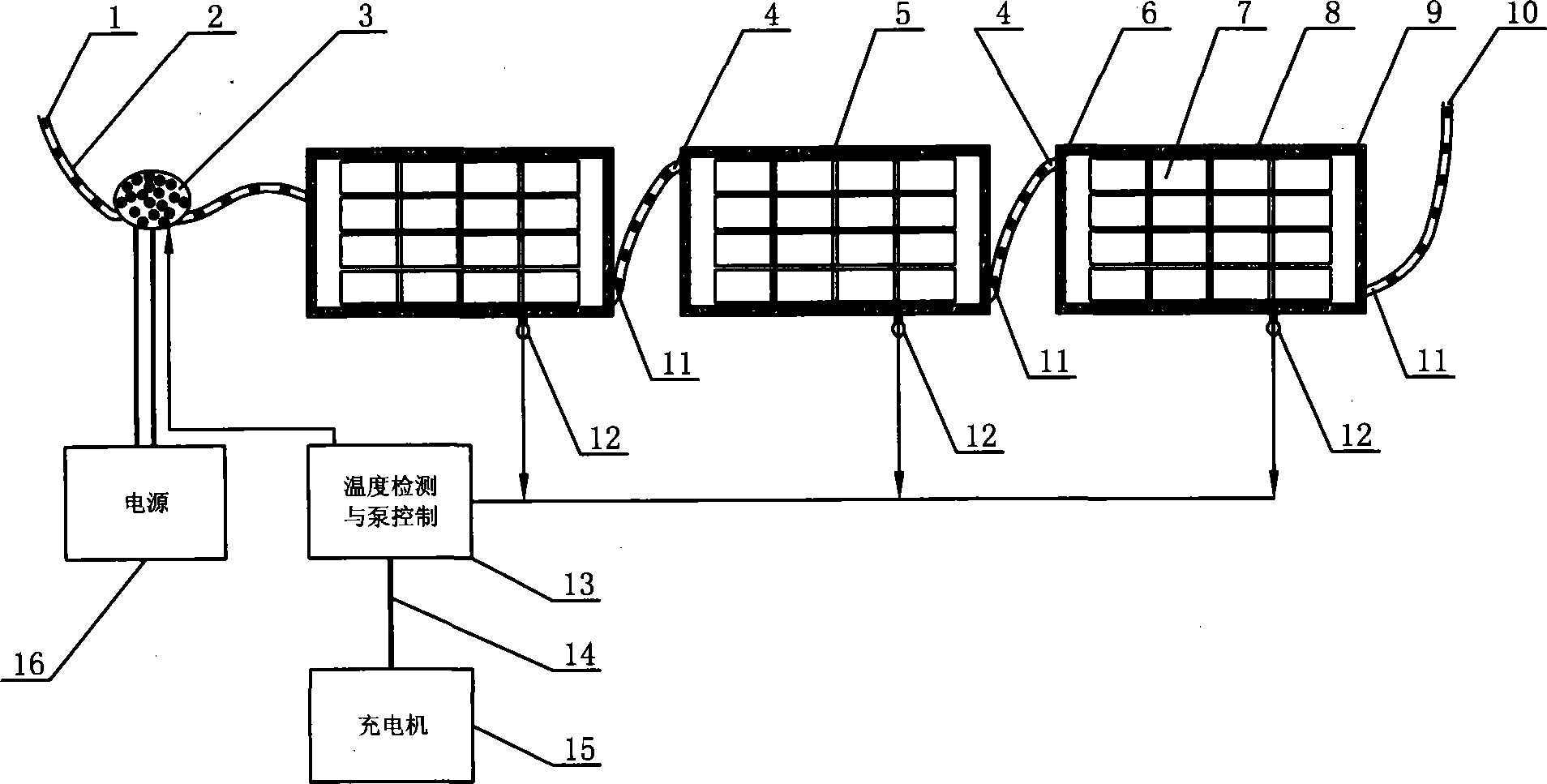

[0012] exist figure 1 , figure 2 Middle: Each group of 8 battery packs is in the shape of a rectangular parallelepiped. The main entrance 1 of the battery pack is provided with a pump 3, and the pump 3 is connected to a power source 16. The battery pack 8 is provided with a battery unit 7 electrically connected to each other. The battery unit 7 consists of a or a plurality of battery cells electrically connected to each other, the battery pack 8 is provided with a heat insulating sleeve 5, and the battery pack 8 is sealed and packaged, and most or all of each battery unit 7 is surrounded by a gap filled with cooling liquid 9, All the gaps filled with cooling liquid 9 are interconnected, one end of the battery pack 8 is provided with a cooling liquid inlet 4, the other end of the battery pack 8 is provided with a cooling liquid outlet 11, and a temperature sensor 12 is provided in the gap filled with cooling liquid 9, The control unit 13 is composed of the pump 3, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com