Friction control method of magnetic micro-nano texture surface and device

A technology of micro-nano texture and control method, which is applied in the direction of measuring device, mechanical device, test sample preparation, etc., can solve problems such as friction and wear, friction adhesion, microstructure adhesion, etc., to reduce internal stress, Controllable composition, inhibiting the effect of expansion and spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the concrete steps of friction control method are:

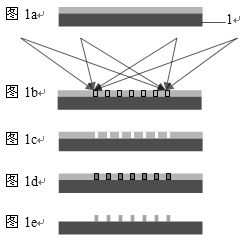

[0025] 1. Preparation of a surface with micro-nano texture: combined use of laser lithography and electrochemical deposition. First, implement laser lithography on the sample, spin-coat the photoresist on the surface of the substrate material, spin-coat with a homogenizer, and then dry it at 70-110°C for 20 minutes; adjust the average power of the laser within the setting range At 5~100mW, make the laser form interference fringes on the surface of the sample; turn off the pulse laser system, take out the sample, and dry it at 80~100°C for 20min; finally put the sample into the developer, when the exposed part on the photoresist is exposed After the developer solution is dissolved, take out the sample, rinse the developer solution with deionized water, and dry it naturally; after the completion, electrochemical deposition is performed on the sample; electrochemical deposition parameters: forward and rever...

Embodiment 2

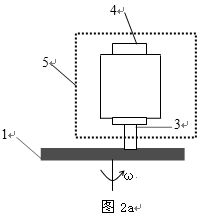

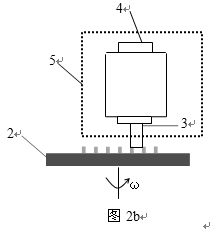

[0034] Embodiment 2: or the magnetization treatment is real-time regulation and control of the magnetic field strength method: the DC power supply, the coil and the friction and wear testing machine are connected sequentially, the coil is wound on the friction and wear testing machine, the sample is placed in the coil, and an adjustable voltage is applied to make the The magnetic field strength generated by the coil is controlled at 2.25×10 4 ~4.5×10 4 A / m; adopt the working mode of pin-disk wear, set the speed at 50~300r / min, time 10~30min, and apply a load of 0.1~50N. When the pin-disc is working, keep the coil energized to control the magnetic field strength generated by the coil at 2.25 ×10 4 ~4.5×10 4 A / m; The experimental test of friction and wear is carried out on the sample, and the experimental results are obtained after the experiment is completed.

[0035] The control device includes: sample, pin 3, load 4, friction and wear testing machine 5 and coil 8; the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com