Jogging element-based infrared detector for modulating GaN HEMT channel current

An infrared detector and channel current technology, applied in the field of infrared detectors, can solve the problems of unfavorable integration of reference optical paths, electrochemical corrosion, difficult process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

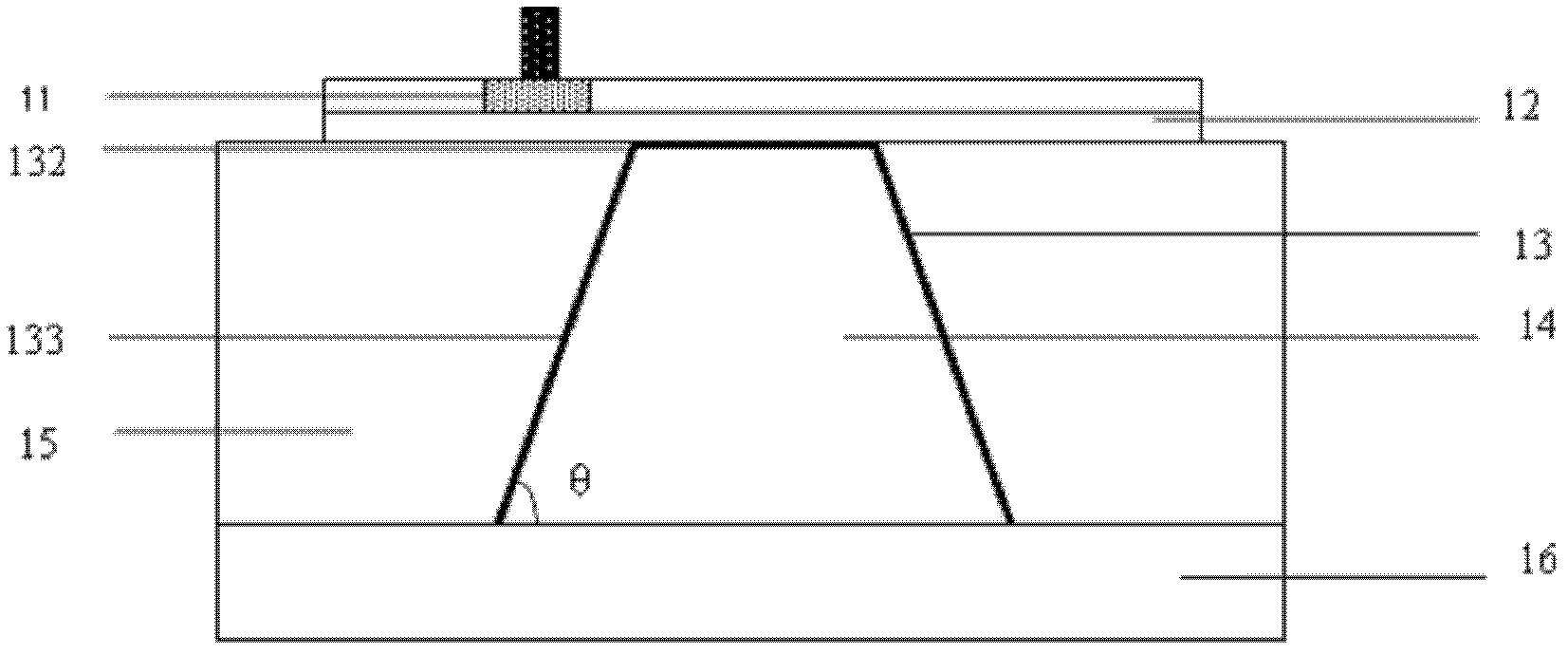

[0020] GaN / AlGaN HEMT is used as the HEMT device, Al is used as the infrared reflection layer in the light wave absorption auxiliary layer, and SiN x For the energy-absorbing film, the inclination angle θ of the prism gas-filled cavity is 45° as an example. The device consists of the following parts: GaN / AlGaN HEMT device, micro-moving element, light-wave absorption auxiliary layer, gas-filled cavity, substrate, absorbing light wave gas, A vertical GaN-based force-electrically coupled infrared detector composed of a window layer. The preparation process is as follows:

[0021] 1. First use the diffusion deposition process in Si / Al with GaN / AlGaN structure 2 O 3 The sheet forms a heterojunction to prepare a GaN / AlGaN heterojunction HEMT. For the Si substrate epitaxial GaN method, it is necessary to etch Si to leave the GaN / AlGaN diaphragm and HEMT; if Al is used 2 O 3 Substrate epitaxial GaN / AlGaN, you need to remove Al by polishing and ICP etching 2 O 3 Substrate.

[0022] 2. Usin...

Embodiment 2

[0026] GaN / AlGaN HEMT is used as the HEMT device, Ag is used as the infrared reflection layer in the light wave absorption auxiliary layer, and SiN x For the energy-absorbing film, the inclination angle θ of the prism gas-filled cavity is 45° as an example. The device consists of the following parts: GaN / AlGaN HEMT device, micro-moving element, light-wave absorption auxiliary layer, gas-filled cavity, substrate, absorbing light wave gas, A vertical GaN-based force-electrically coupled infrared detector composed of a window layer. The preparation process is as follows:

[0027] 1. First use the diffusion deposition process in Si / Al with GaN / AlGaN structure 2 O 3 The sheet forms a heterojunction to prepare a GaN / AlGaN heterojunction HEMT. For the Si substrate epitaxial GaN method, it is necessary to etch Si to leave the GaN / AlGaN diaphragm and HEMT; if Al is used 2 O 3 Substrate epitaxial GaN / AlGaN, you need to remove Al by polishing and ICP etching 2 O 3 Substrate.

[0028] 2. Usin...

Embodiment 3

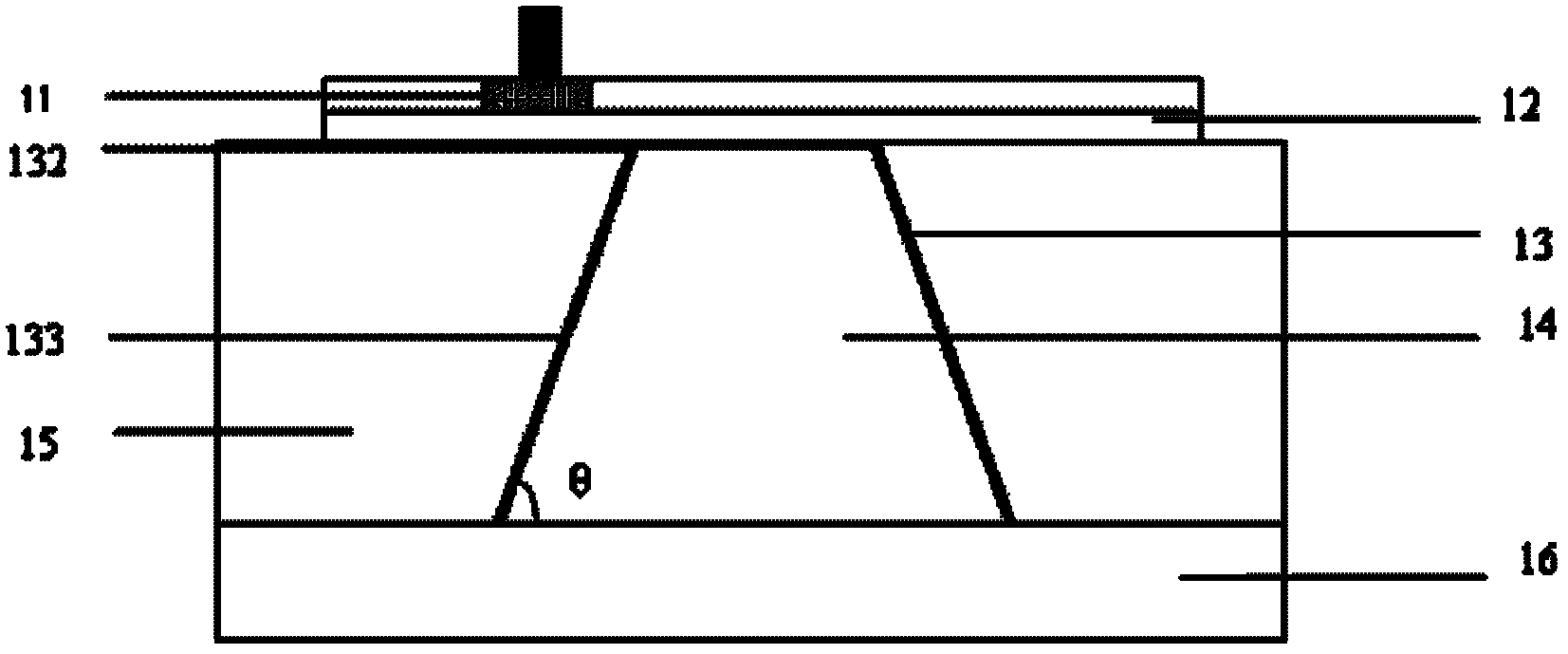

[0032] GaN / AlGaN HEMT is used as the HEMT device, Al is used as the infrared reflection layer in the light wave absorption auxiliary layer, and SiN x For the energy-absorbing film, take the round-table gas-filled cavity as an example. The device consists of the following parts: GaN / AlGaN HEMT device, micro-movement element, light-wave absorption auxiliary layer, gas-filled cavity, substrate, light-wave gas absorption, vertical type window layer GaN-based force-electrically coupled infrared detector. The preparation process is as follows:

[0033] 1. First use the diffusion deposition process in Si / Al with GaN / AlGaN structure 2 O 3 The sheet forms a heterojunction to prepare a GaN / AlGaN heterojunction HEMT. For the Si substrate epitaxial GaN method, it is necessary to etch Si to leave the GaN / AlGaN diaphragm and HEMT; if using Al 2 O 3 Substrate epitaxial GaN / AlGaN, you need to remove Al by polishing and ICP etching 2 O 3 Substrate.

[0034] 2. Using MEMS technology to form a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com