Heat transfer element capable of generating longitudinal vortex and element pair thereof

A longitudinal vortex, element technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as large pressure loss and rising heat exchange index with the same power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

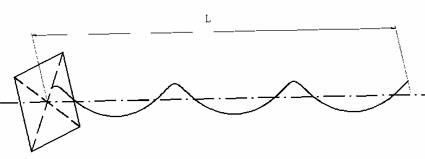

[0016] Refer to attached figure 1 , the construction idea of the single helical rib is introduced in detail. Orthogonally stretch the square [1] along the helix [2] into a helical cylinder [3]. The helix is obtained by rotating a point outside the axis at a constant speed clockwise with the straight line as the axis and advancing the length L of the rib by an angle α. Under the condition of L=9mm, the effective α parameters are 90°, 180°, 270°, 360°, 450°, 540°. With the increase of α at the same flow rate, the pressure loss of the fluid passing over the rib decreases and the heat transfer coefficient fluctuates little, so the enhanced heat transfer index increases at the same power consumption; the larger α is, the smaller the growth rate is. When α is 540°, The growth trend is close to the level; α=540° is 8% higher than that of α=90° with the same power consumption enhanced heat transfer index.

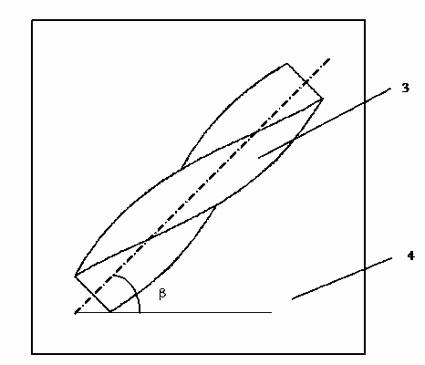

[0017] Refer to attached figure 2 , detailing the geometry of the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com