Asymmetric retractable transverse slot pipe heat exchanger

An asymmetric, scaling technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed tubular duct assembly, etc., can solve the problems of unsuitable gas-vapor heat exchange, low comprehensive heat transfer efficiency, etc. The effect of comprehensive heat transfer efficiency, improving comprehensive heat transfer efficiency and reducing flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

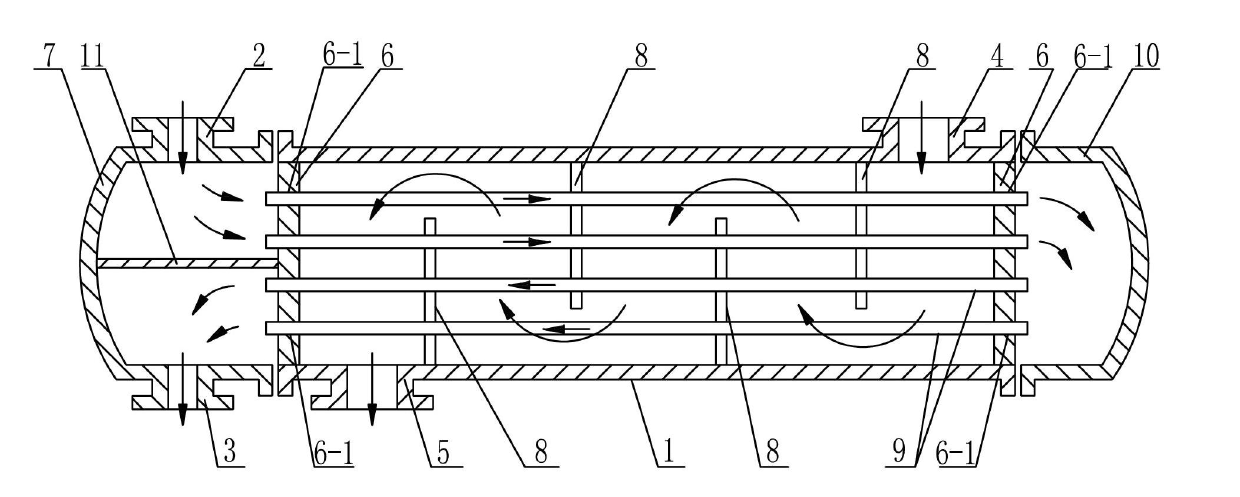

[0015] Specific implementation mode one: combine Figure 1-Figure 4 To illustrate this embodiment, the asymmetric scaling type horizontal groove tube heat exchanger of this embodiment includes a shell 1, a cold medium inlet pipe 2, a cold medium outlet pipe 3, a heat medium inlet pipe 4, a heat medium outlet pipe 5, two A tube sheet 6, a first head 7, a second head 10, a horizontal partition 11, a plurality of baffles 8 and a plurality of heat exchange tubes 9, and a tube sheet 6 is installed on the inner walls of both ends of the shell 1, A first sealing head 7 is installed on one end surface of the casing 1, a second sealing head 10 is installed on the other side end surface of the casing 1, a heat medium inlet pipe 4 is arranged on the top of the casing 1, and a heat medium inlet pipe 4 is arranged on the bottom of the casing 1. The medium outlet pipe 5, the first head 7 is provided with a horizontal partition 11, the top of the first head 7 is provided with a cold medium i...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination Figure 1-Figure 3 This embodiment will be described. The asymmetric zoom-type transverse groove pipe of this embodiment is made of carbon steel or alloy steel. Such setting is convenient for processing and forming, and has low cost and long service life. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

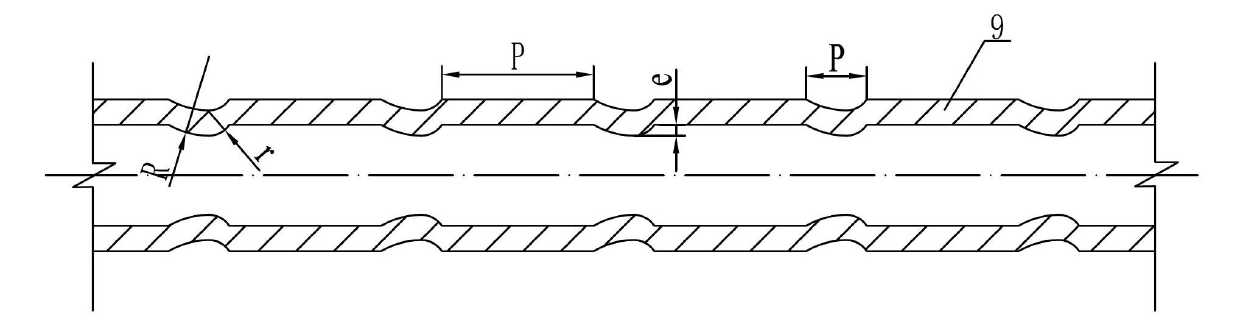

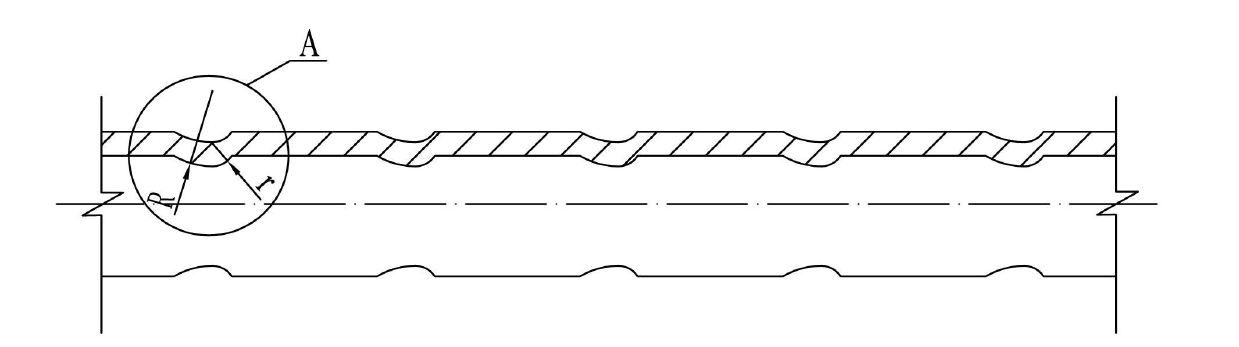

[0018] Specific implementation mode three: combination figure 2 with image 3 To illustrate this embodiment, the length P of the light pipe segment between two adjacent annular grooves on the asymmetric zoom-type transverse groove pipe of this embodiment is 5 mm to 15 mm. With this setting, the length of the bare pipe section is moderate, and the number of annular grooves is suitable, the cost of rolling the pipe by the machine tool is relatively low, and it is also conducive to the increase of the comprehensive heat transfer efficiency of the pipe pass. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com