A sintering machine trolley provided with an elastic sealing strip

A technology of elastic sealing strips and locomotives, which is applied in the direction of lighting and heating equipment, furnace types, furnaces, etc., to achieve the effect of reducing the amount of spare parts, reducing the air leakage rate of trolleys, and reducing the frequency of fence replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

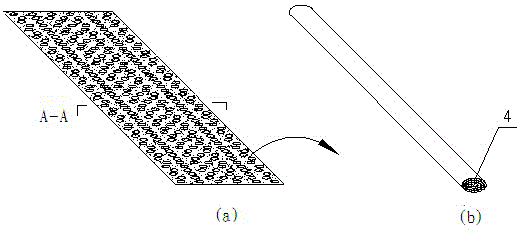

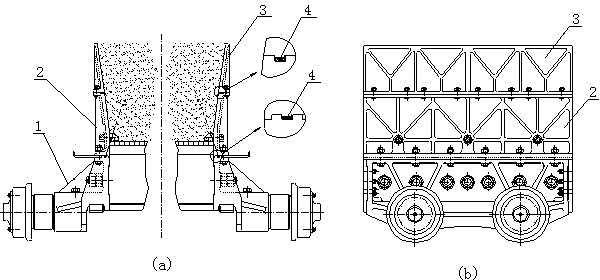

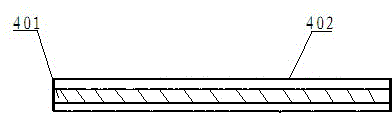

[0041] Such as image 3 (A) and image 3 (B) The sintering machine trolley of this embodiment, the area of the trolley is 400m 2 , It includes upper fence 3, lower fence 2 and trolley body 1. The seals between upper fence 3 and lower fence 2 and between lower fence 2 and trolley body 1 are respectively provided with elastic sealing strips 4. The elastic sealing strip 4 is a metal graphite sealing strip, which is a strip structure formed by crimping a layered structure, and the layered structure includes a metal layer 401 and a graphite layer 402. The graphite layer 402 is embedded and pressed on the upper and lower surfaces of the metal layer 402. The seals between the upper fence 3 and the lower fence 2 and between the lower fence 2 and the trolley body 1 are provided with mutually matched bosses and grooves. The elastic sealing strip 4 is pressed into the concave by the bosses. In the slot.

[0042] In the sintering machine trolley of this embodiment, the assembly structure...

Embodiment 2

[0044] Such as image 3 (A) and image 3 (B) The area of the sintering machine trolley of this embodiment is 500m 2 , The trolley design adopts the technology of elastic sealing strip 4 between the upper fence 3 and the lower fence 2, the effective sintering volume of the trolley (length×width×height) is 1400×5000×900mm, and the lower rails on both sides of the trolley body 1 Plate 2 (length×height) 1400×500mm; upper fence 3 (length×height) 1400×400mm on both sides of the trolley body 1; the contact surface between the lower fence plate 2 and the trolley body 1 (length× Width) 1400×110mm, the contact surface between the lower fence 2 and the upper fence 3 of the trolley (length×width) 1400×80mm, the seals of the upper fence 3, the lower fence 2 and the lower fence 2 and the trolley The seal of the body 1 is sealed in the form of grooves and bosses, and the elastic sealing strip 4 is pressed into the grooves by the bosses. Among them, the size of the groove at the upper end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com