Power system of water pump for long-distance water supply trucks and long-distance water supply truck provided with system

A technology for power systems and water supply trucks, applied in fluid pressure actuation system components, fluid pressure actuation devices, pump control, etc., can solve problems such as hydraulic pumps are easily damaged, layout is not flexible, and energy loss is large, and achieve system efficiency High efficiency, flexible layout and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

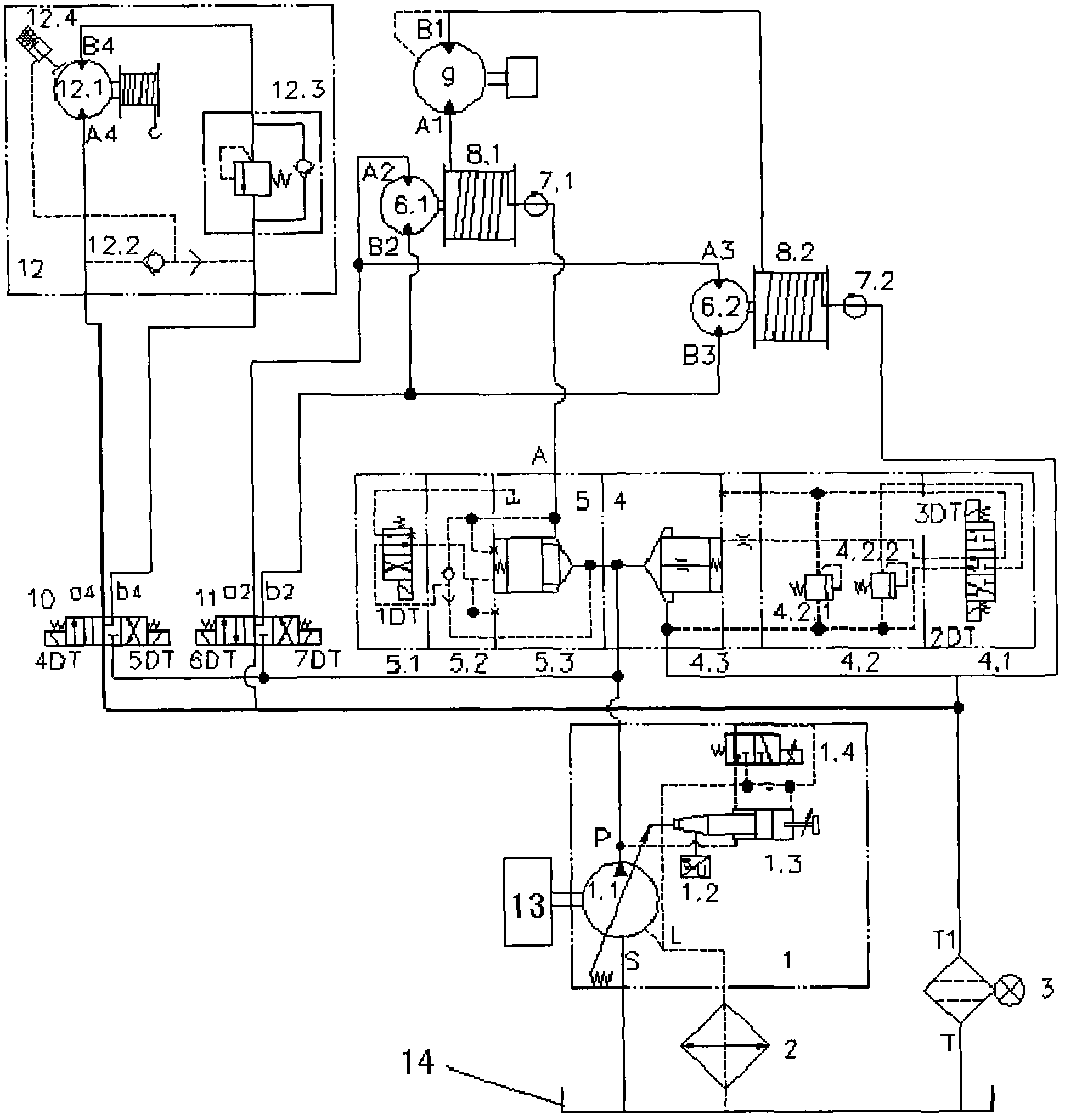

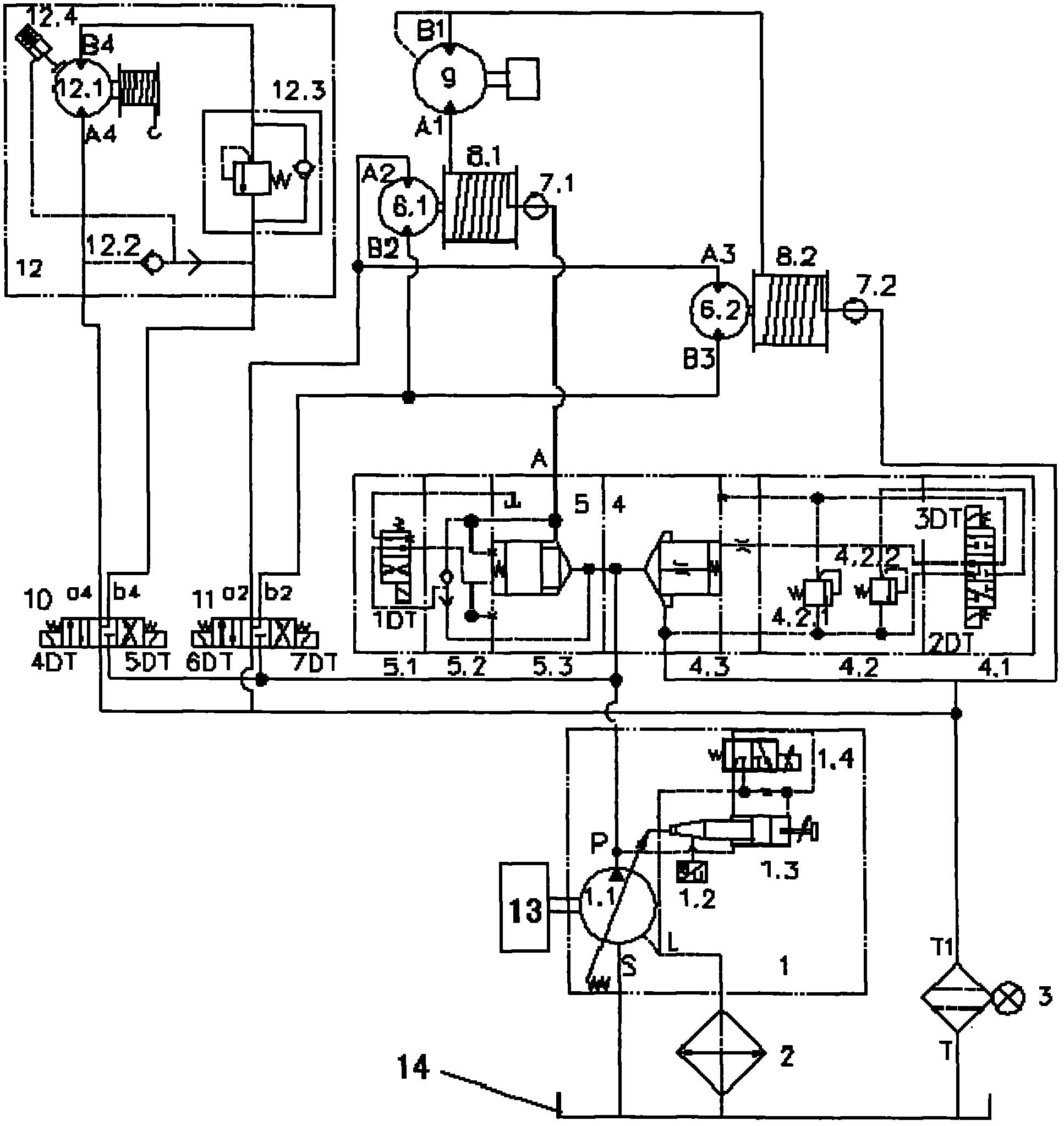

[0018] like figure 1 As shown, the power system of the remote water supply truck water pump of the present invention includes engine 13 (here, generally refers to diesel engine), the proportional displacement variable pump 1 driven by engine 13, the safety unloading valve 4 that plays the role of setting pressure, On-off valve 5 for switching, hydraulic motor 9 for driving the water pump, oil tank 14, filter 3 on the hydraulic pipeline and oil return pipeline. Here, the proportional displacement variable pump 1 includes a base pump 1.1, a position sensor 1.2, a variable cylinder 1.3 and a proportional valve 1.4. Preferably, the safety unloading valve 4 includes a first pilot valve 4.1, a pressure regulating cover plate 4.2 and a pressure insert 4.3, which constitute a two-way cartridge type safety unloading valve 4, which can adjust two high pressures; the switch valve 5 includes The second pilot valve 5.1, the shuttle valve cover plate 5.2 and the direction plug-in 5.3 const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com