Supporting method for construction of swirl well

A swirl well and earth excavation technology, which is applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve problems such as construction difficulties of swirl wells, and achieve the effects of fast construction speed, low construction cost, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

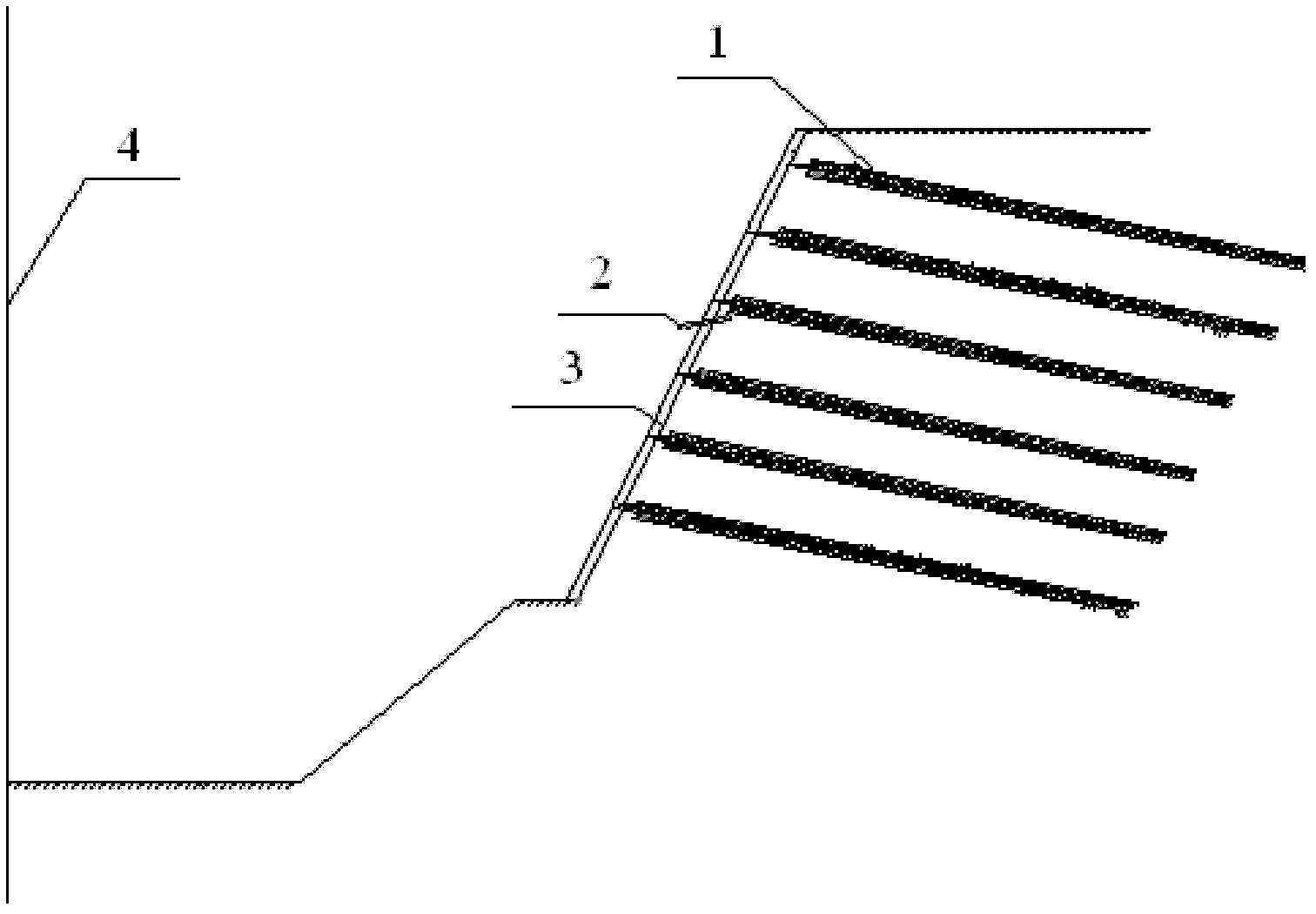

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Construction principles:

[0027] The "Technical Specifications for Building Slope Engineering", "Technical Specifications for Building Foundation Pit Support" and the design schemes implemented in the construction method of soil nail wall support swirl well.

[0028] Firstly, based on the swirling well design drawings and geological survey reports, and on the basis of fully combining the on-site construction environment, a scientific construction plan was formulated in accordance with quality assurance, capital saving and construction period consideration, and attention was paid to ensuring construction safety.

[0029] Fully prepare for construction before construction: collect design drawings and geological survey data, determine the construction plan; determine the construction equipment and construction sequence according to the construction plan;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com