Citric acid wrinkle proofing technology for real silk fabrics

A technology of anti-wrinkle finishing and silk fabric, which is applied in the direction of fabric surface trimming, heating/cooling fabric, fiber treatment, etc., which can solve the problems of poor safety, easy to pollute the environment, and affect the dyeing performance of fabrics, so as to improve the anti-wrinkle effect and guarantee The effect of anti-wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

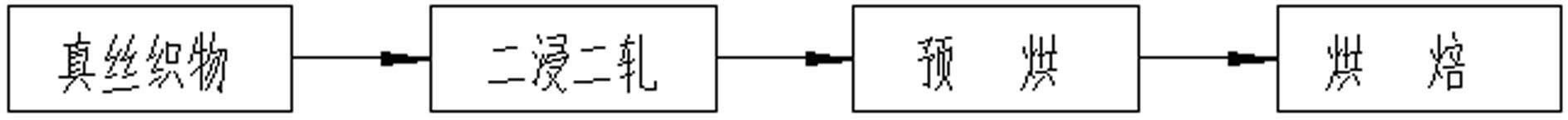

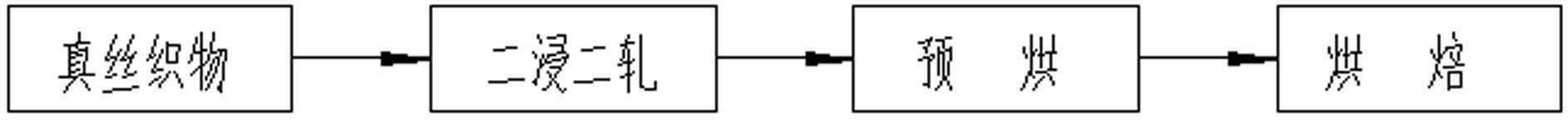

[0025] Such as figure 1 As shown, the silk fabric citric acid anti-wrinkle finishing process of the present invention includes the following processing steps: the real silk sample is immersed in the anti-wrinkle finishing solution in a padding machine, two dipping and two rolling are carried out, the first soaking is 5 minutes, the second time Soak for 3 minutes to make the excess rate 70%. Then use an oven to pre-bake at 85°C for 3 minutes, and bake at 120-150°C for 1-2 minutes. The volume percentage of each component in the anti-wrinkle finishing liquid formula is as follows:

[0026] CA(%): 0-10,

[0027] SHPP(%): 0-9,

[0028] Additive (%): 0-6,

[0029] Penetrant (%): 0.2,

[0030] The rest is water, and the main component of the penetrant is C 7-9 h 15-19 O(CH 2 CH 2 O) 5 H.

Embodiment 2

[0032] The difference with Example 1 is that the volume percentage of each component in the total liquid volume in the anti-wrinkle finishing liquid formula is as follows:

[0033] CA(%): 3-5,

[0034] SHPP(%): 3,

[0035] PAA (%): 4,

[0036] Penetrant (%): 0.2,

[0037] The rest is water.

[0038] Baking conditions are: 130°C×2min.

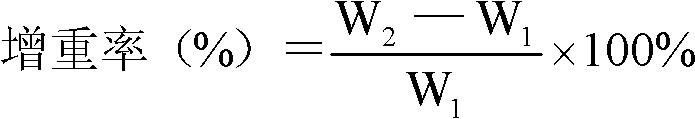

[0039] Carry out weight gain rate, whiteness value and tear strength performance test to embodiment 2, test result is compared with the situation that CA adopts other dosage and does not carry out anti-wrinkle treatment, data result is shown in the following table 1:

[0040] Table 1

[0041] CA[(w / w)%]

[0042] It can be seen from Table 1 that when the amount of CA is between 0-5%, the crease recovery performance of silk fabrics is gradually improved, and the recovery performance begins to decline after it is greater than 5%. The whiteness of silk fabrics decreased with the increase of CA content, and the weight gain rate increa...

Embodiment 3

[0044] The difference with Example 1 is that the volume percentage of each component in the total liquid volume in the anti-wrinkle finishing liquid formula is as follows:

[0045] CA(%): 6,

[0046] SHPP(%): 3,

[0047] Additive (%): 0-6,

[0048] Penetrant (%): 0.2,

[0049] The rest is water.

[0050] Baking conditions are: 130°C×2min.

[0051] Carry out the performance test of whiteness value to embodiment 3 under the situation of not using additive and using the same amount of different types of additives, the test results are shown in the following table 2:

[0052] Table 2

[0053] Additives

[0054] PAAA

[0055] It can be seen from Table 2 that triethylamine, glyoxal, and PAA as additives can all improve the anti-wrinkle finishing effect of CA on silk fabrics, and PAA has the most obvious improvement on anti-wrinkle effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com