Vapor phase inhibitor for metal natural gas gathering and transporting pipeline and preparation method for vapor phase inhibitor

A gas-phase corrosion inhibitor and natural gas technology, applied in the field of gas-phase corrosion inhibitor and its preparation, can solve the problem that the corrosion inhibitor cannot inhibit the corrosion of oil and gas transmission pipelines, etc., to overcome the weak alkalinity, easy to use, and reduce economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

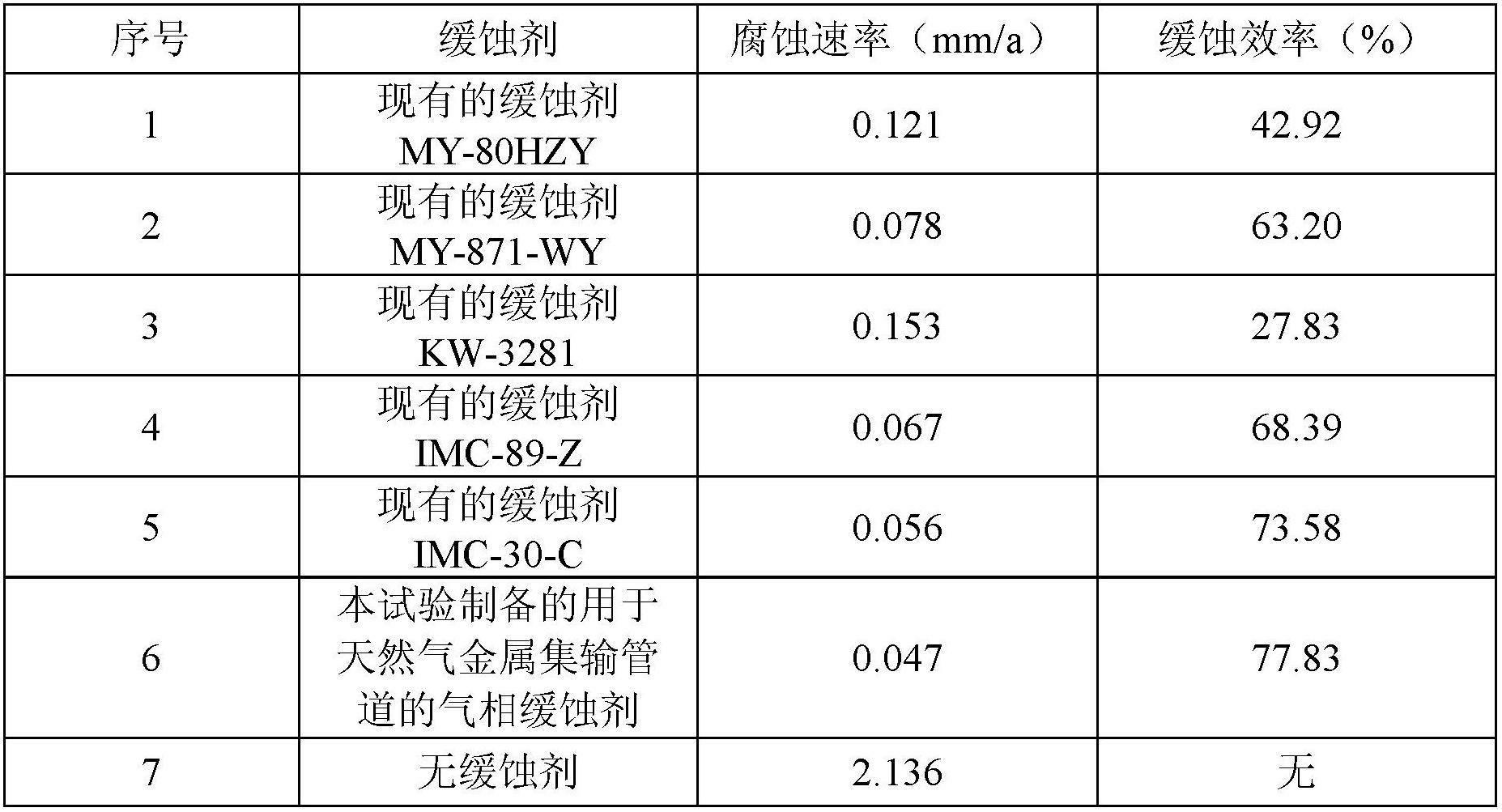

Examples

specific Embodiment approach 1

[0009] Embodiment 1: This embodiment is a gas-phase corrosion inhibitor for natural gas metal gathering and transportation pipelines. The gas-phase corrosion inhibitor for natural gas metal gathering and transportation pipelines is formed by mixing components A and B. The B component accounts for 300ppm to 500ppm (ppm: one millionth) of the volume of the A component, wherein the A component is composed of 10% to 20% N-methyldiethanolamine, 3% by mass fraction. ~7% ethanolamine, 1%~3% diethylenetriamine, 0.10%~0.25% imidazole, 0.25%~0.40% sec-octanol polyoxyethylene ether, 1.00%~1.50% benzotriazole , 0.80% to 1.00% of quinoline and 68% to 80% of distilled water; wherein the B component is a sulfonate type anionic surfactant.

[0010] Corrosion inhibitor is an organic alcohol amine molecule with both hydrophilic and hydrophobic amphiphilic properties, and a surfactant and a diffusing agent are used to coordinate the release agent, so that the interaction force between the molecu...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sulfonate-type anionic surfactants are alkylbenzene sulfonates, α-olefin sulfonates, alkyl sulfonates or Alpha-sulfomonocarboxylate.

specific Embodiment approach 3

[0018] Embodiment 3: The present embodiment is a preparation method of a gas-phase corrosion inhibitor for natural gas metal gathering and transportation pipelines, and is specifically completed according to the following steps:

[0019]1. Preparation of component A: 1. Weighing: weigh 10%-20% N-methyldiethanolamine, 3%-7% ethanolamine, 1%-3% diethylenetriamine, 0.10%~0.25% imidazole, 0.25%~0.40% sec-octanol polyoxyethylene ether, 1.00%~1.50% benzotriazole, 0.80%~1.00% quinoline and 68%~80% distilled water 2. Prepolymerization: firstly, 10%~20% N-methyldiethanolamine, 3%~7% ethanolamine, 1%~3% diethylenetriamine and 0.10% N-methyldiethanolamine, 1%~3% diethylenetriamine and 0.10 %~0.25% of imidazole is mixed evenly, and heated and stirred for 2h~4h under the conditions of a temperature of 90℃~100℃ and a stirring speed of 100r / min~150r / min to obtain a prepolymer; ③. ② The prepared prepolymer was cooled to room temperature, and then added in step ① according to the mass fractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com