Fiber-reinforced resin-matrix composite furniture material and preparation method thereof

A fiber-reinforced resin and furniture technology, which is applied in the field of fiber-reinforced resin-based composite furniture materials and its preparation, can solve the problems of easy aging, easy water absorption of wood, heavy metal materials, etc., and achieve super corrosion resistance, excellent UV resistance, Good effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

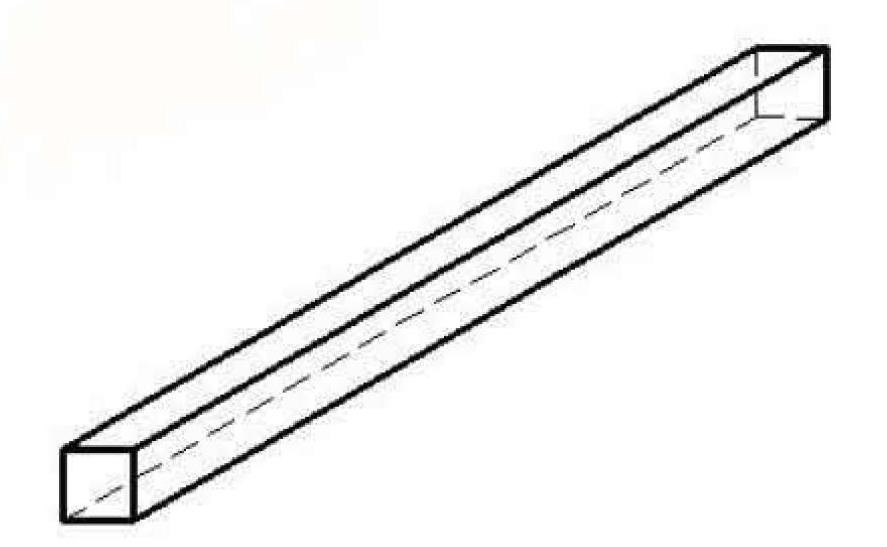

[0031]The production process of carbon fiber table legs is as follows: First, carbon fiber unidirectional prepreg (produced by Weihai Huixing Fiber Products Co., Ltd.) with an area density of 150 grams is wrapped on a nylon air duct with a diameter of 75 mm at plus or minus 45 degrees. A total of 6 layers are covered. Finally, wrap a layer of 3K carbon fiber twill prepreg with a layer density of 200 grams. Put it into the lower mold of the steel mold, cover the upper mold (the cross-sectional size of the mold cavity is 60X60 mm), and push it into the pressure plate of the press (manufactured by Dongguan Zhengwen Machinery Co., Ltd.). Start to pressurize and raise the temperature to 120 degrees. At the same time, start to blow air to the nylon duct, and the air pressure is 0.6MPa. After two hours, the air pressure is removed, the mold is pulled out from the platen, and cooled naturally. The product comes out of the mold with a cut length of 70 cm. Remove the nylon duct. Fi...

Embodiment 2

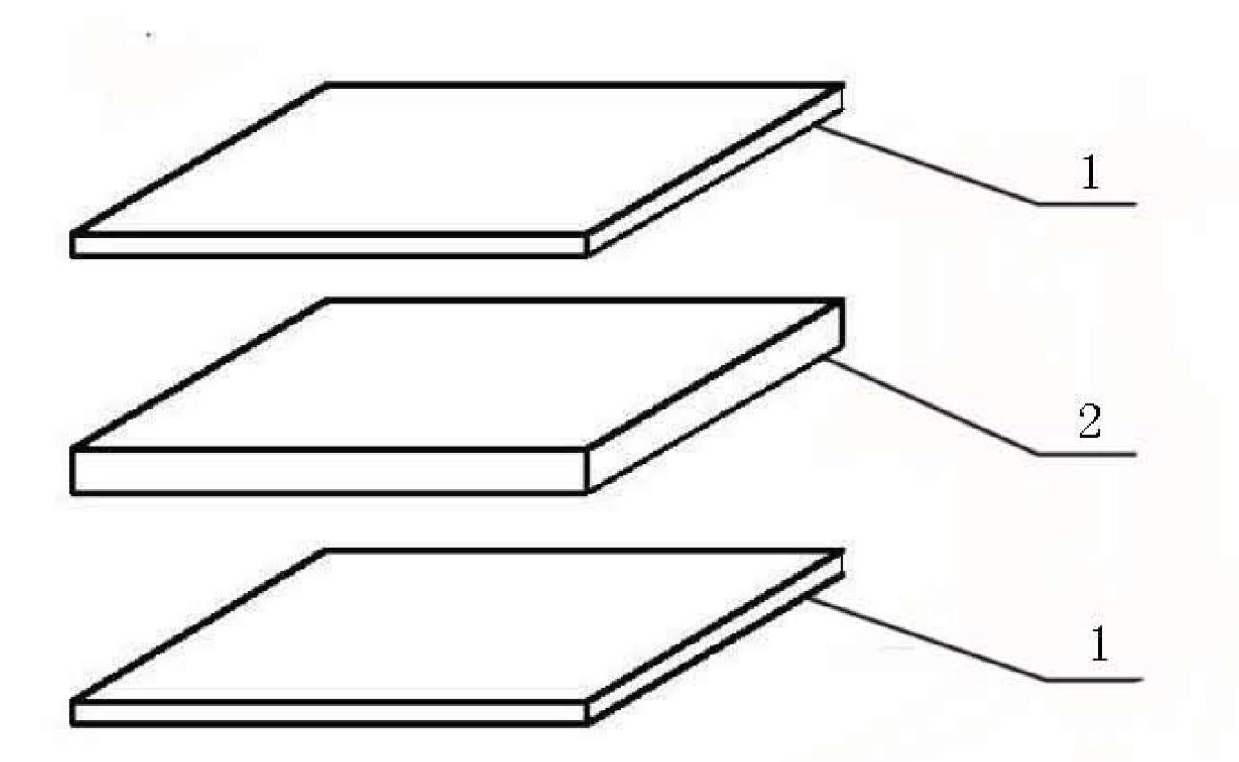

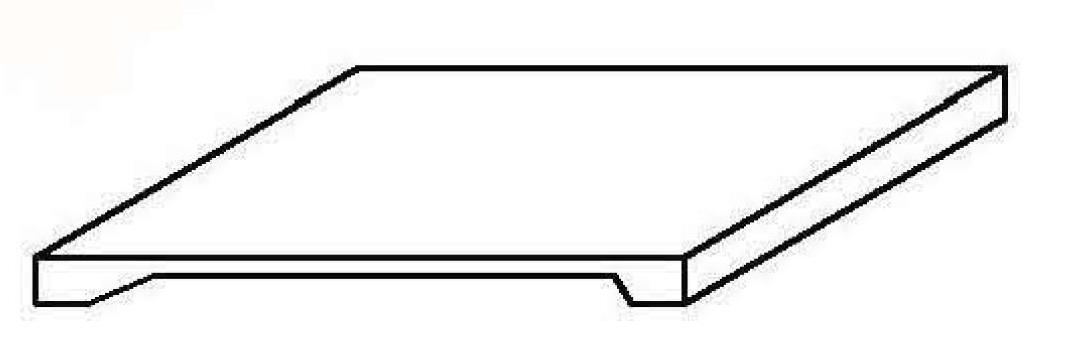

[0033] Dining table top: Its production method is resin vacuum introduction molding process. The panel size is 1400mm X800mm X50mm. First apply the release agent in the mold cavity, and then spray the clear gel coat. After the gel coat is solidified, spread a layer of 3K twill carbon cloth on it, and then spread two layers of 450 grams of glass fiber chopped strand mat. Then lay release cloth, diversion net, diversion tube and vacuum bag on top. Start the vacuum introduction of the vinyl ester resin. After curing for 4 hours, lay polypropylene honeycomb panels of different sizes. A layer of hand-laid fiberglass board is glued on top. After demoulding, sand and polish the table top. Form the table top with 3K carbon fiber parts on the mirror surface.

Embodiment 3

[0035] The woven carbon fiber dining table assembled with parts such as those in Embodiment 1 and Embodiment 2 has a size of 1400 mm in length, 800 mm in width and 750 mm in height.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com