High-strength glass decorative steel slag concrete prefabricated art stone and manufacture method thereof

A technology of steel slag concrete and glass, which is applied in the direction of paving, manufacturing tools, and ceramic molding machines with prefabricated blocks. Effects of compressive and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

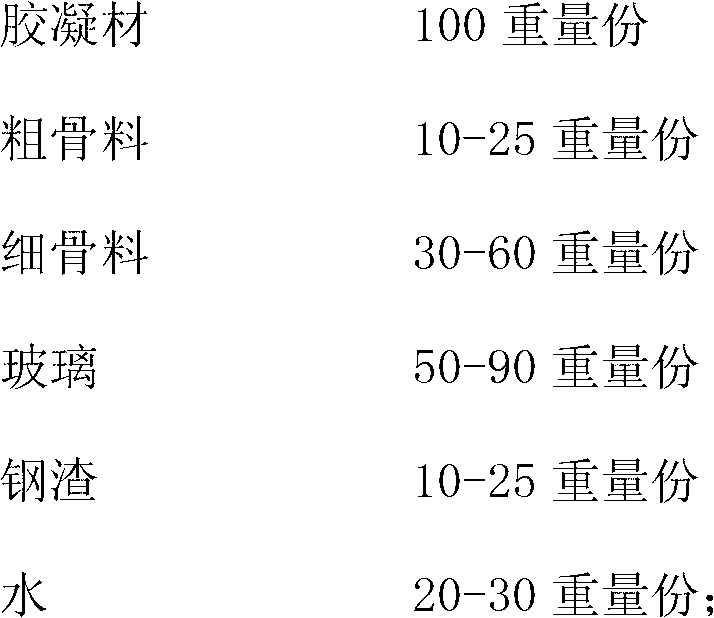

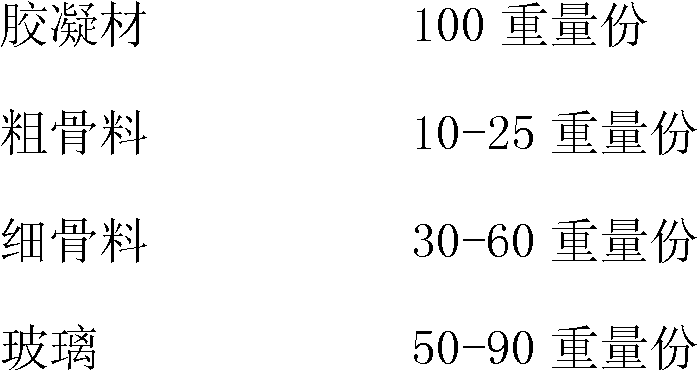

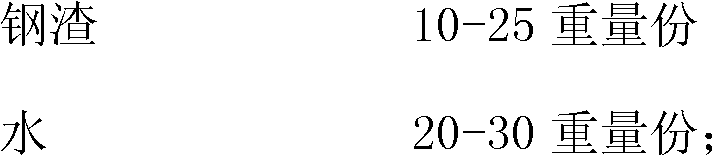

[0058] Base concrete ratio (weight ratio):

[0059] Water: cement: coarse aggregate: fine aggregate = 10%: 40%: 40%: 10%. The cement is ordinary Portland cement with a strength grade of 42.5; the coarse aggregate is stone with a particle size range of 2-6mm; the fine aggregate is fine sand with a particle size range of 0.1-0.5mm.

[0060] Surface concrete ratio (weight ratio):

[0061] Among them: cementitious material = white cement: ordinary Portland cement = 70%: 30%

[0062] Table 1 surface layer material formula

[0063]

[0064] The preparation method is as follows:

[0065] Step 1: After measuring the base material and surface material according to the design ratio, add them to the mixing device for uniform mixing.

[0066] The second step: evenly spread the mixed base material in the supported mold, and cover the cover;

[0067] Step 3: Push it into the vacuum equipment to evacuate to below 0.5MPa, 30 seconds to 60 seconds;

[0068] Step 4: Perform vibration a...

Embodiment 6-8

[0080] Base concrete ratio (weight ratio): cement is ordinary portland cement, strength grade is 42.5; coarse aggregate is stone, particle size range is 2-6mm; fine aggregate is fine sand, particle size range is 0.1-0.5 mm.

[0081] Table 3 base material formula

[0082]

[0083] Surface concrete proportioning (weight ratio) is the same as embodiment 1.

[0084] The preparation method is as follows:

[0085] Step 1: After measuring the base material and surface material according to the design ratio, add them to the mixing device for uniform mixing.

[0086] The second step: evenly spread the mixed base material in the supported mold, and cover the cover;

[0087] Step 3: Push it into the vacuum equipment to evacuate to below 0.5MPa, 30 seconds to 60 seconds;

[0088] Step 4: Perform vibration and pressurization for 30 seconds to 90 seconds; among them, the pressure of vibration pressurization is 100KN, the vibration force of vibration is 100KN, and the vibration freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com