Polytetrafluoroethylene isostatic pressure molding device and pipeline lining method by aid of same

A technology of isostatic pressing and polytetrafluoroethylene, which is applied in the field of static pressing forming devices and pipeline linings, can solve the problems of low density, poor permeability resistance and poor tensile strength of polytetrafluoroethylene lining, and achieve High tensile strength, strong impermeability, high temperature and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

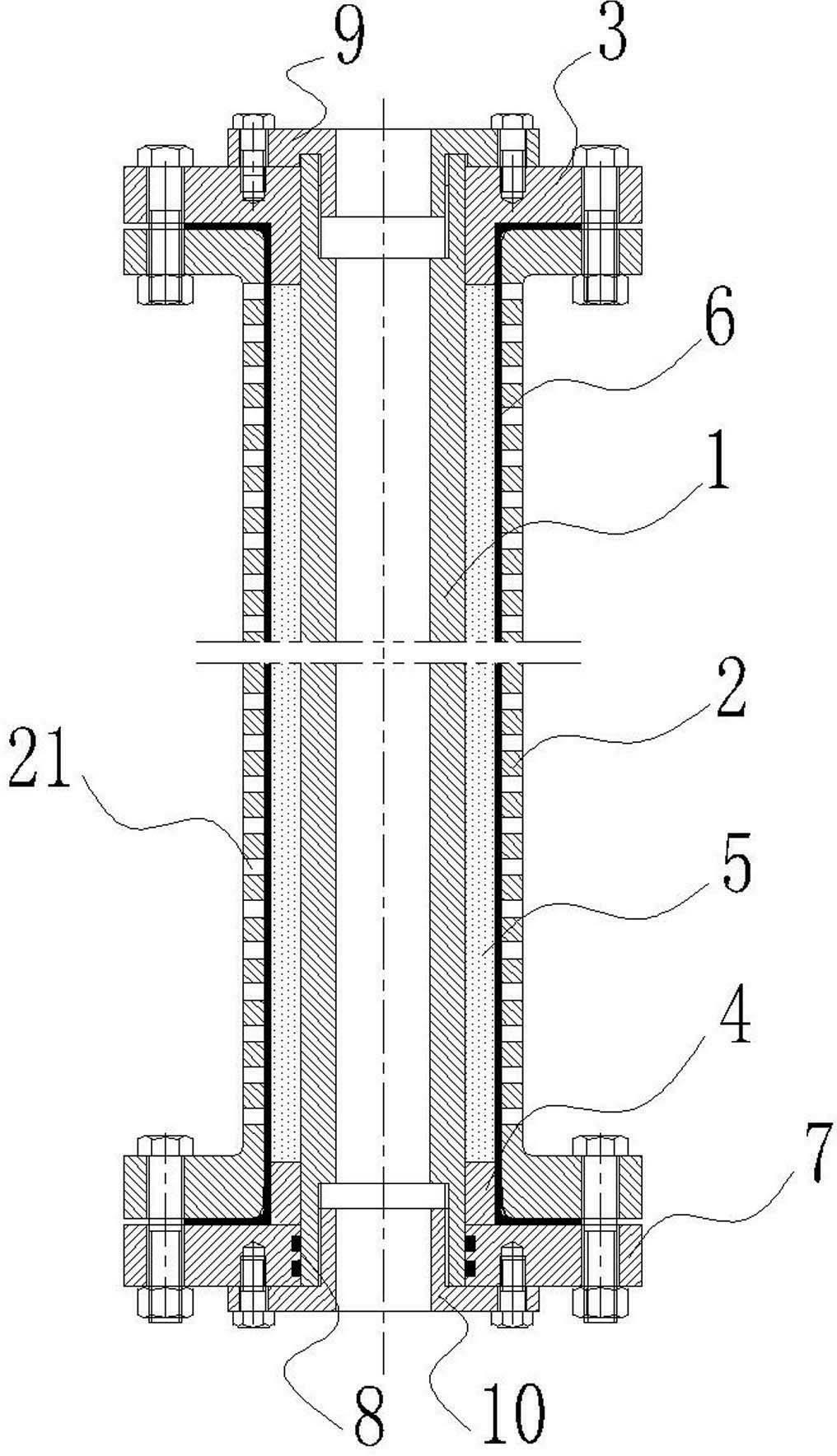

[0035] Such as figure 1 As shown, a polytetrafluoroethylene isostatic pressing molding device of the present invention includes a tubular inner mold 1 and a tubular outer mold 2 set outside the tubular inner mold 1, and the two ends of the tubular outer mold 2 extend horizontally outward respectively. A tubular elastic membrane layer 6 of equal diameter is inserted in the inner cavity of the tubular outer mold 2, the elastic membrane layer 6 is made of rubber material and is flatly attached to the inner wall surface of the tubular outer mold 2 and the two ends extend horizontally On the end face of the tubular outer mold 2, an upper sealing ring 3 is set on the outer side of the upper end of the tubular inner mold 1, and a lower sealing ring 4 is set on the outer side of the lower end, and the inner ring surfaces of the upper sealing ring 3 and the lower sealing ring 4 are sealed and connected in the tubular inner mold. On the mold 1, the outer ring surfaces are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com