Resin pressing curved surface numerical control machining clamp for performing precision forging on blade tenon root

A fixture and resin technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large positioning error, large clamping deformation, insufficient stability, etc., achieve high positioning accuracy, and solve the problem of clamping , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

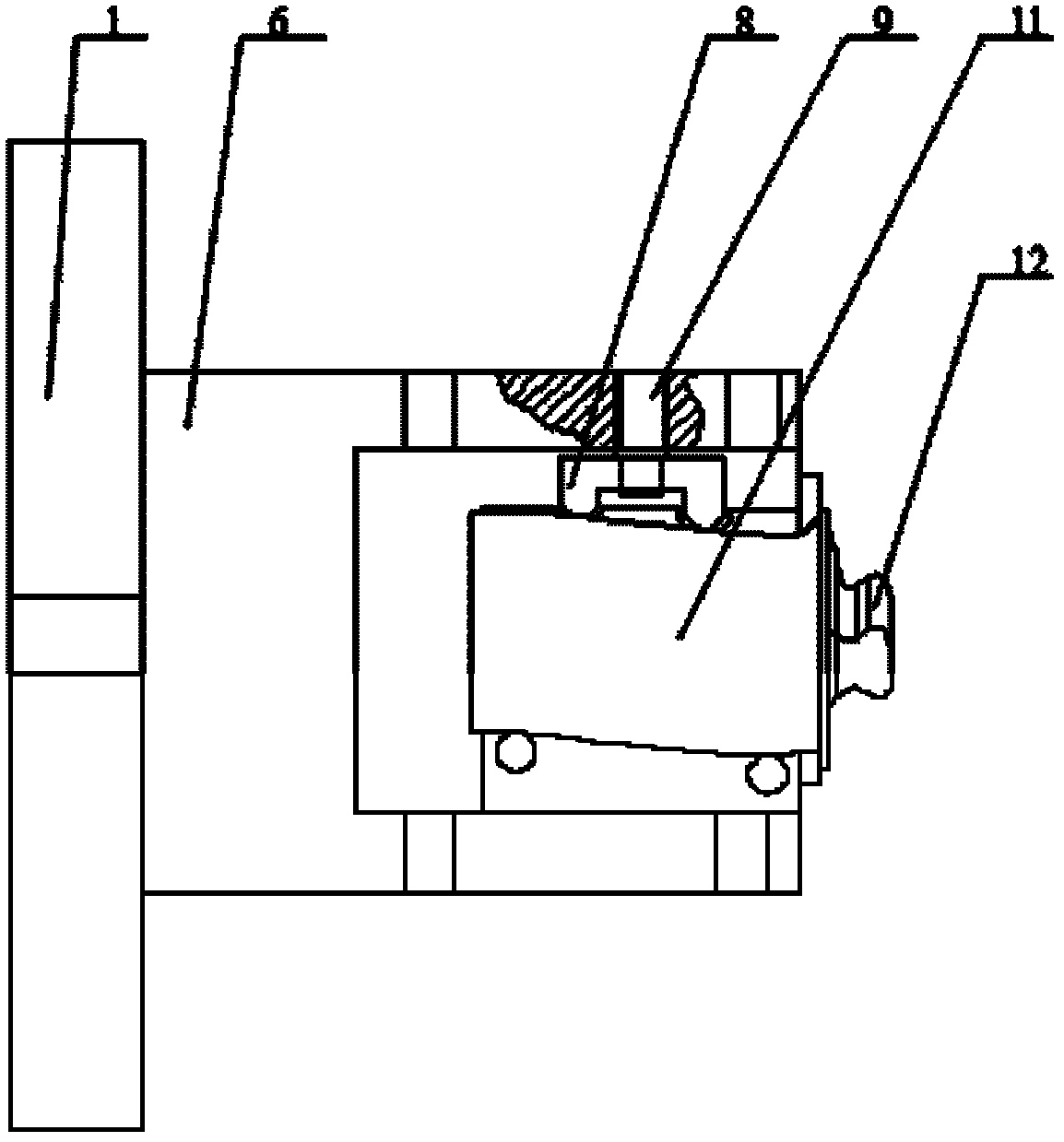

[0024] This embodiment is a resin-compressed curved surface numerically controlled precision forging blade tenon root fixture.

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , the resin-pressed curved surface numerically controlled precision forging blade tenon root fixture of the present invention includes a rotary table 1, a fixture box cover 2, a box cover top plate 3, a positioning pin 3 4, an eccentric pin shaft 5, a fixture box body 6, and an upper bolt 7 , adjusting block 8, positioning screw 9, fastening pin one 10, blade 11, blade tenon root 12, blade body positioning pin one 13, lower bolt 14, blade body positioning pin two 15, metal belt one 16, metal belt two 17 , metal strip three 18, metal strip four 19, box top plate 20, positioning pin two 21, positioning pin one 22, fastening pin two 23;

[0026] The rotary table 1 is fixed and installed on the machine tool table by bolts; the fixture box 6 fixed on the rotary table 1 is connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com