Online detection and correction system for laser-guided deep-hole drilling

A laser-guided and deep-hole drilling technology, which is applied in the direction of drilling/drilling equipment, positioning measurement in boring machines/drilling machines, manufacturing tools, etc., can solve problems such as difficult observation of processing parts and tool conditions, and achieve the promotion of deviation correction problems, The effect of improving parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

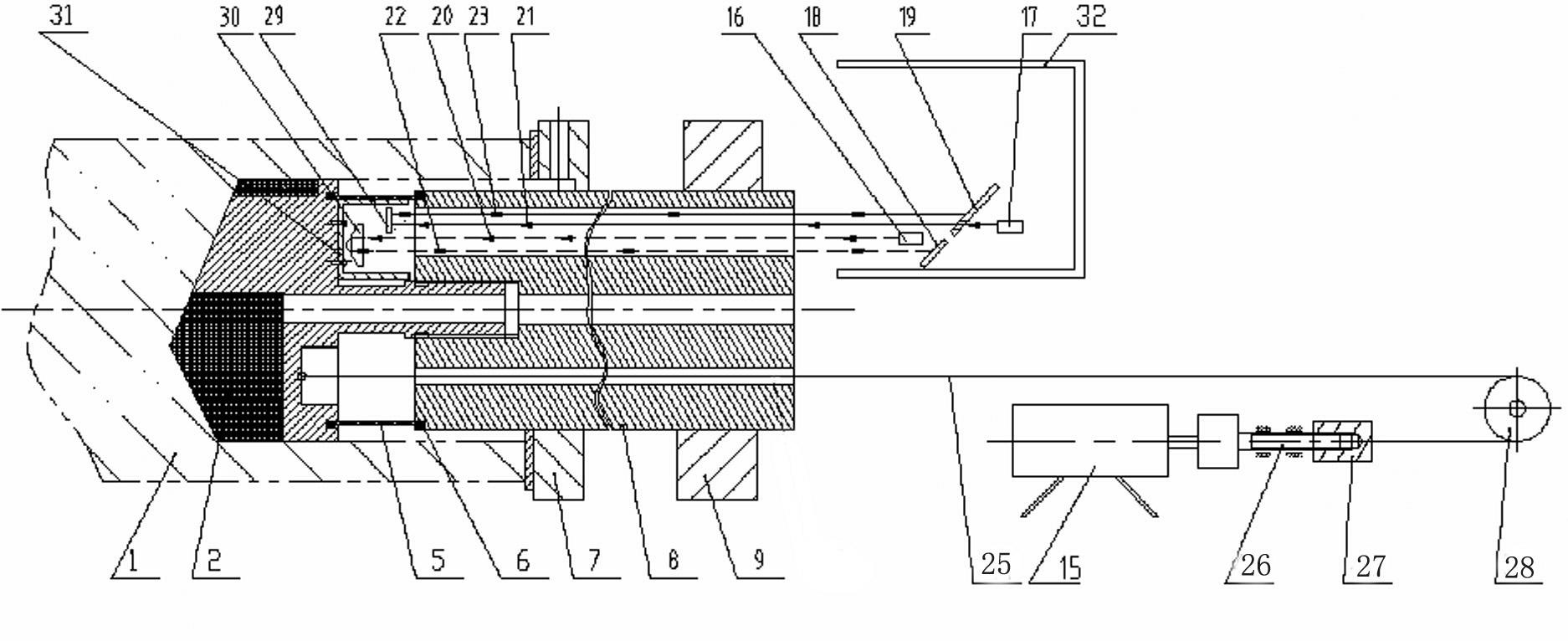

[0043] Embodiment 1: as figure 1 As shown, the workpiece 1 of the present invention rotates and the drill bit 2 feeds. There is no bottom hole in the workpiece, and a deep hole with a horizontal axis needs to be drilled.

[0044] The present invention comprises workpiece 1, drill bit 2, drill pipe 8, oil feeder 7, feed box 9, No. 1 light source 16, No. 2 light source 17, drill bit position sensor 18, drill bit attitude sensor 19, reflecting mirror 29, cube pyramid Prism 30, stay cord 25, the motor 15 that corrects drill bit usefulness, computing controller, computer.

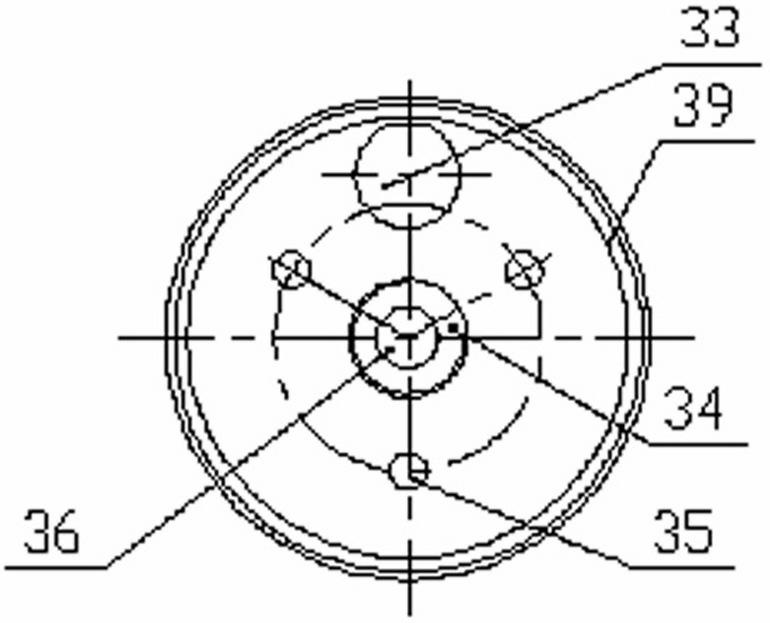

[0045] The drill bit 2 is fixed on the drill rod 8 through its threaded section 42, and the drill rod 8 is fixed on the feed box 9 for only feeding motion. The oil feeder 7 provides high-pressure oil for deep hole processing. The oil flows in from the hole of the oil feeder 7, passes through the gap between the drill rod 8 and the workpiece 1 and the gap between the blades 38 of the drill bit 2, and is dischar...

Embodiment 2

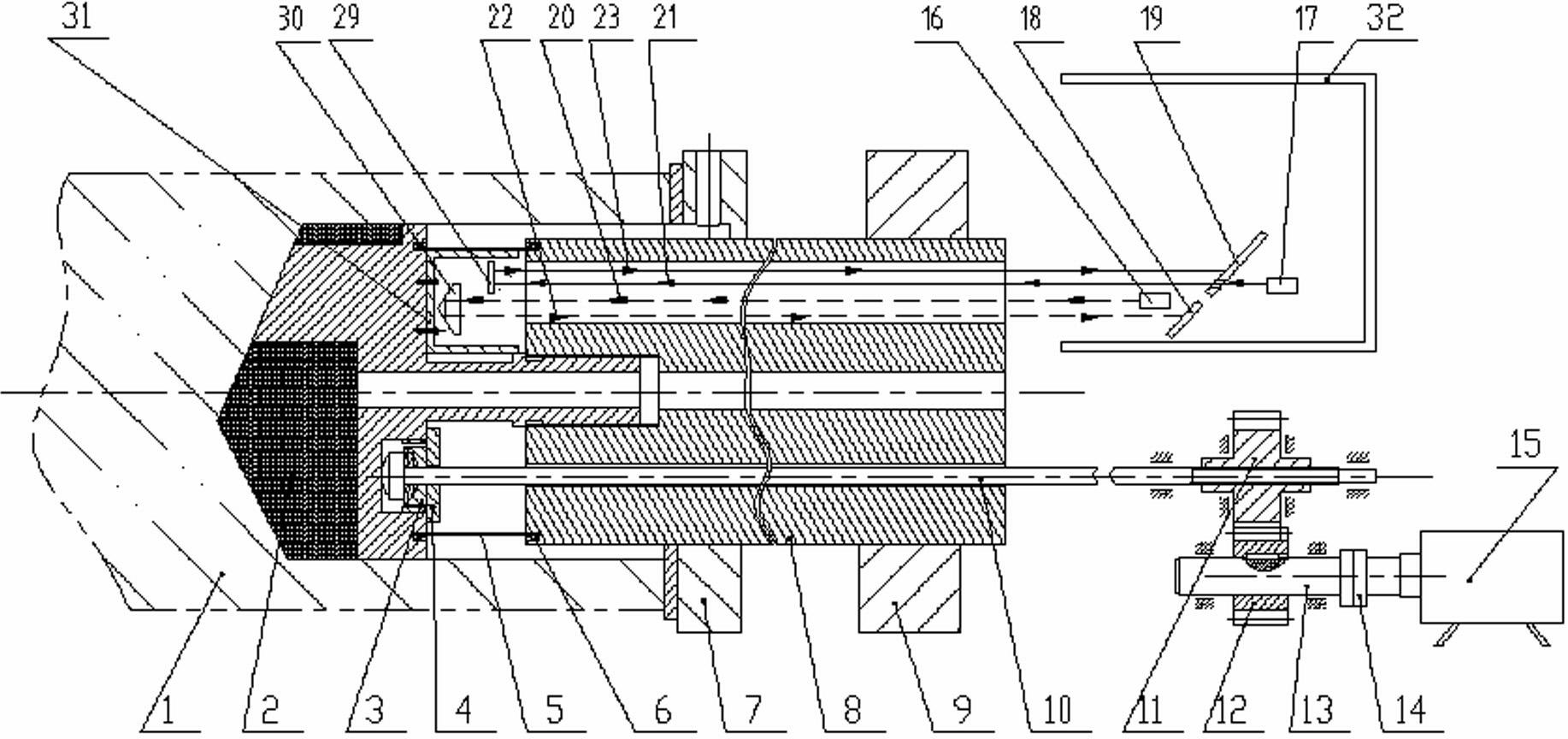

[0058] Embodiment 2: as figure 2 As shown, the afterburning mechanism adopts the form of a tie rod.

[0059] Pull rod type force adding mechanism, the pull rod head is positioned at the connecting hole 45 of the drill bit back, and the pull rod head acts on the spherical washer 3, and the spherical washer acts on the cover 4, and the cover is fixed in the connecting hole 45 on the drill bit back. The motor 15 drives the output shaft 13 through the coupling 14, and drives two gears (or pulleys) to rotate. The axial movement of the gear 11 is limited by the parts fixed on the feed box. The inner hole of the gear 11 is threaded, and the pull rod The threads at the rear end cooperate to drive the pull rod 10 . Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com