Hot water cleaning machine structure

A technology of hot water cleaning and blower, applied in the field of cleaning, can solve the problems of poor cleaning effect of high-pressure cold water cleaning machines, achieve reasonable structure, ensure water supply, and reduce the volume of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

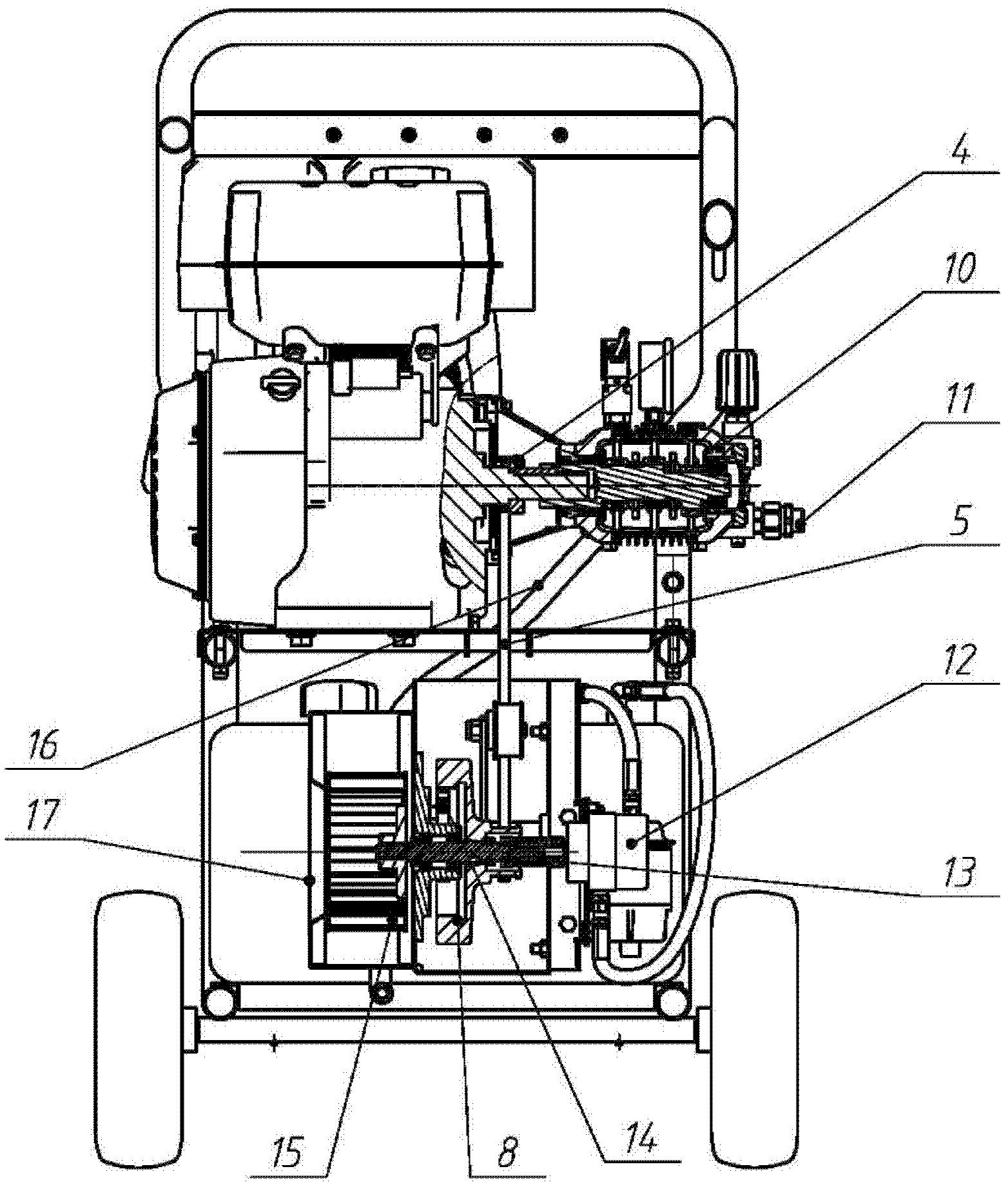

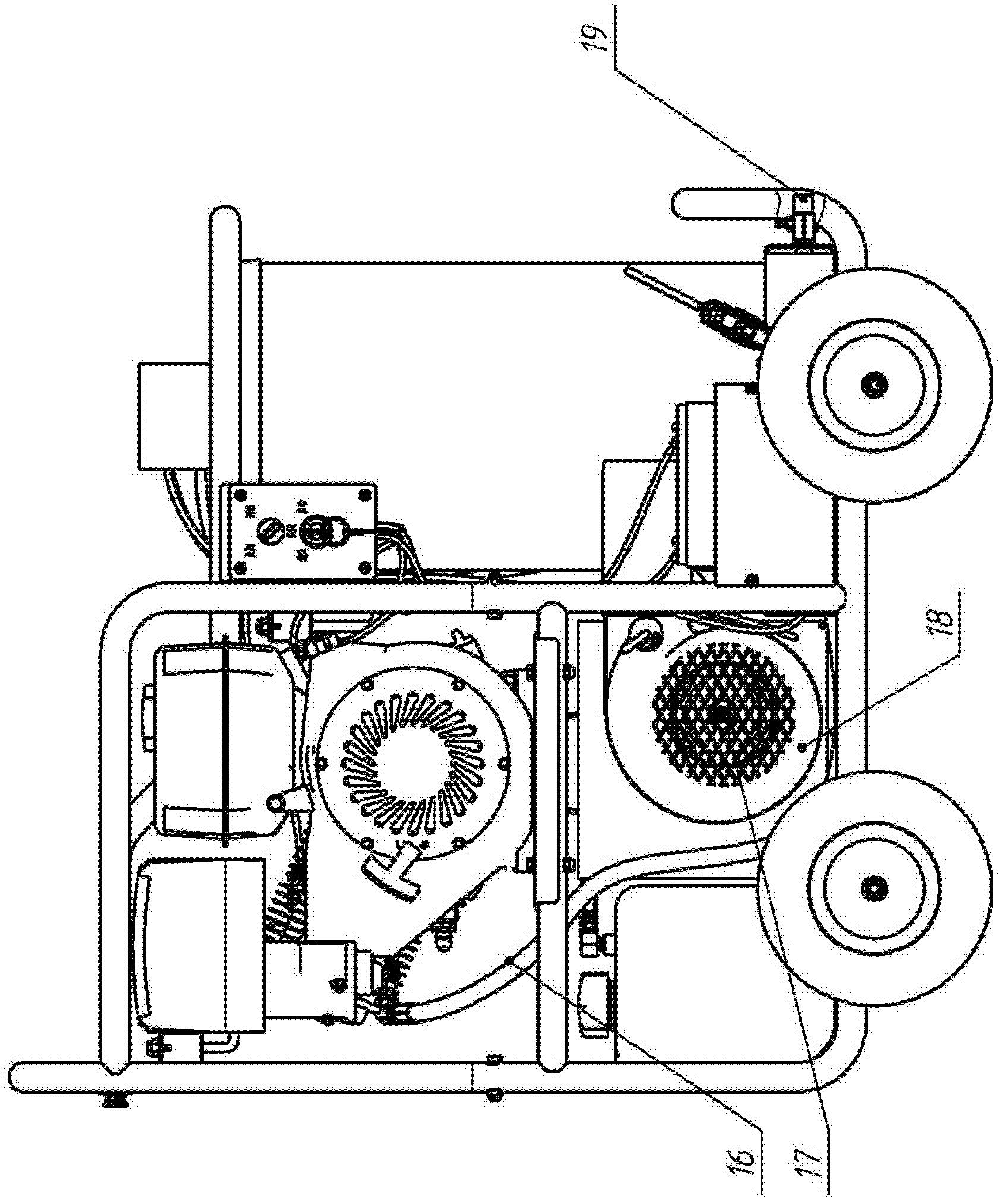

[0018] The invention proposes a structure of a hot water washing machine, including: a high-pressure pump for pressurizing water, a burner for heating water, the high-pressure pump has a water inlet and a water outlet, and the burner It has a combustion chamber and a heat exchange coil, and the water outlet of the high-pressure pump communicates with the heat exchange coil; wherein, the burner integrates a combustion chamber, an oil injector, an ignition electrode, a heat exchange coil, and a wind turbine. and a fuel pump, an oil filter, an igniter and a fan are arranged beside the burner; the oil inlet of the fuel pump is connected to the oil filter and the fuel tank, and the oil outlet of the fuel pump is connected to the electromagnetic Oil valve and fuel injection nozzle, the fuel pump sucks the fuel in the fuel tank, and generates a certain pressure fuel to the nozzle through the electromagnetic oil valve, and the nozzle atomizes the fuel and injects it into the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com