Processing method for frozen and cropped freshwater chicken lobsters capable of being quickly tasty

A freshwater crayfish and processing method technology, applied in the fields of aquatic product processing, food processing and preservation, to achieve the effects of high safety, pollution reduction and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

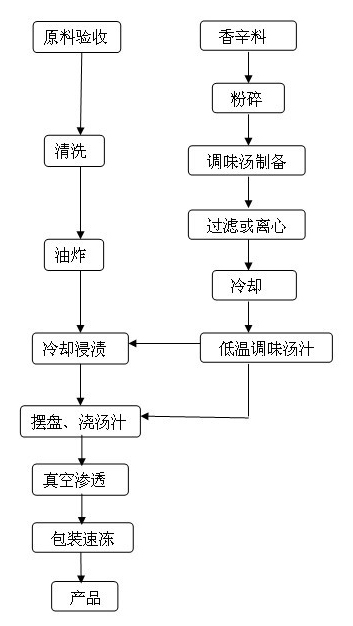

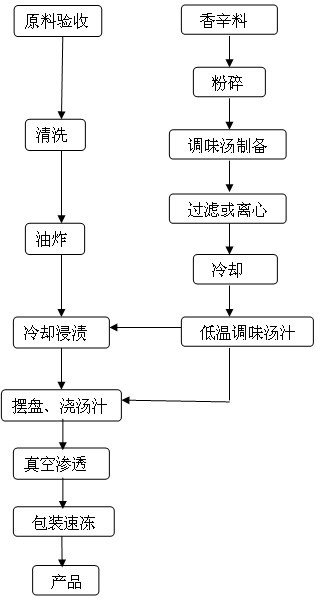

Method used

Image

Examples

Embodiment 1

[0026] Fresh and live freshwater crayfish are used as raw materials, which are selected, cleaned and fried for later use. Use a pulverizer to crush the spices until the average particle size is less than 200 μm, and then put them in a sandwich pot according to the ratio of 1kg water, 80-120g crushed spices, 8-12g seasoning salt, 80-100g sugar, and 5-8g monosodium glutamate. Cook for 15-20 minutes, cool to room temperature, and centrifuge at 2500r / min for 10 minutes to remove seasoning residues to obtain seasoning soup; cool the seasoning soup to 0-4°C with a plate heat exchanger to obtain low-temperature seasoning soup; fry and dehydrate Put the crayfish into the basket with the lifting device, put the crayfish: low-temperature seasoning soup mass ratio 1:3~1:5, put it into the temperature-controlled pool with refrigeration device equipped with low-temperature seasoning soup, cool and dip for 1 ~3 minutes, so that the seasoning substances can quickly penetrate into the shrimp ...

Embodiment 2

[0028] Fresh and live freshwater crayfish are used as raw materials, which are selected, cleaned and fried for later use. Use a pulverizer to crush the spices until the average particle size is less than 200 μm, and then put them in a sandwich pot according to the ratio of 1kg water, 80-120g crushed spices, 8-12g seasoning salt, 80-100g sugar, and 5-8g monosodium glutamate. After cooking for 15-20 minutes, use a 200-mesh filter to remove seasoning residues to obtain seasoning soup; cool the seasoning soup to 0-4°C with a plate heat exchanger to obtain low-temperature seasoning soup; fry and dehydrate the crayfish Put it into a basket with a lifting device, put the crayfish: low-temperature seasoning soup at a mass ratio of 1:3 to 1:5, put it in a temperature-controlled pool with a refrigeration device equipped with low-temperature seasoning soup, cool and soak for 1-3 minutes, Make the seasoning substances penetrate into the shrimp body quickly; remove the cooled and dipped cr...

Embodiment 3

[0030] Fresh and live freshwater crayfish are used as raw materials, which are selected, cleaned and fried for later use. Use a pulverizer to crush the spices until the average particle size is less than 200 μm, and then put them in a sandwich pot according to the ratio of 1kg water, 80-120g crushed spices, 8-12g seasoning salt, 80-100g sugar, and 5-8g monosodium glutamate. After cooking for 15-20 minutes, centrifuge at 4000r / min for 5 minutes to remove seasoning residues to obtain seasoning soup; cool the seasoning soup to 0-4°C with a plate heat exchanger to obtain low-temperature seasoning soup; fry and dehydrate the crayfish Put it into a basket with a lifting device, put the crayfish: low-temperature seasoning soup at a mass ratio of 1:3 to 1:5, put it in a temperature-controlled pool with a refrigeration device equipped with low-temperature seasoning soup, cool and soak for 1-3 minutes, Make the seasoning substances penetrate into the shrimp body quickly; remove the cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com