Pulling wheel type egg product waxing machine

A dial-type, egg-like technology, which is applied in the direction of coating protective layers to preserve eggs, etc., can solve problems such as harsh working environment conditions, complex device structures, and complex mechanical structures, and achieve the effects of simple structure, uniform coating, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

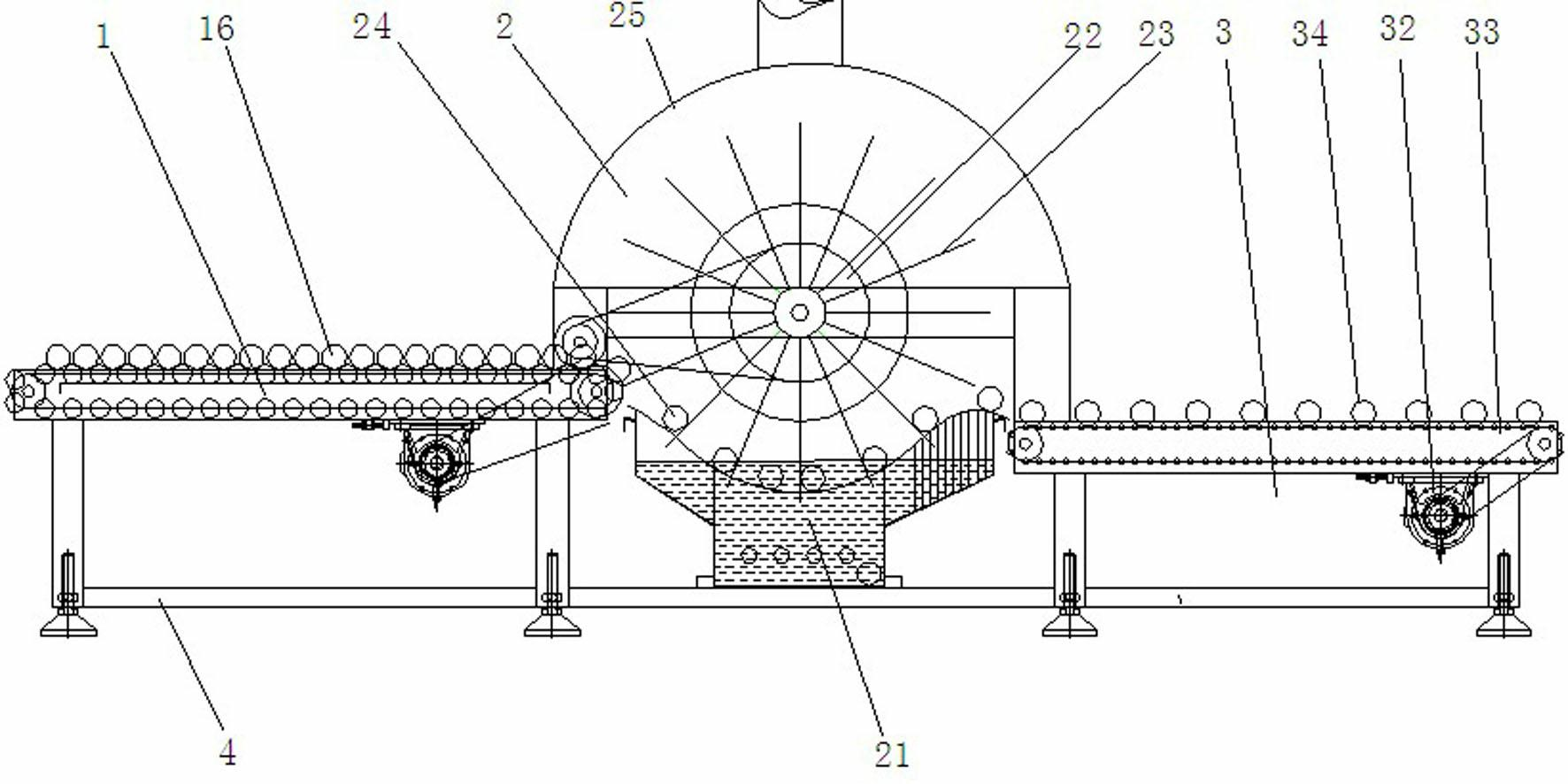

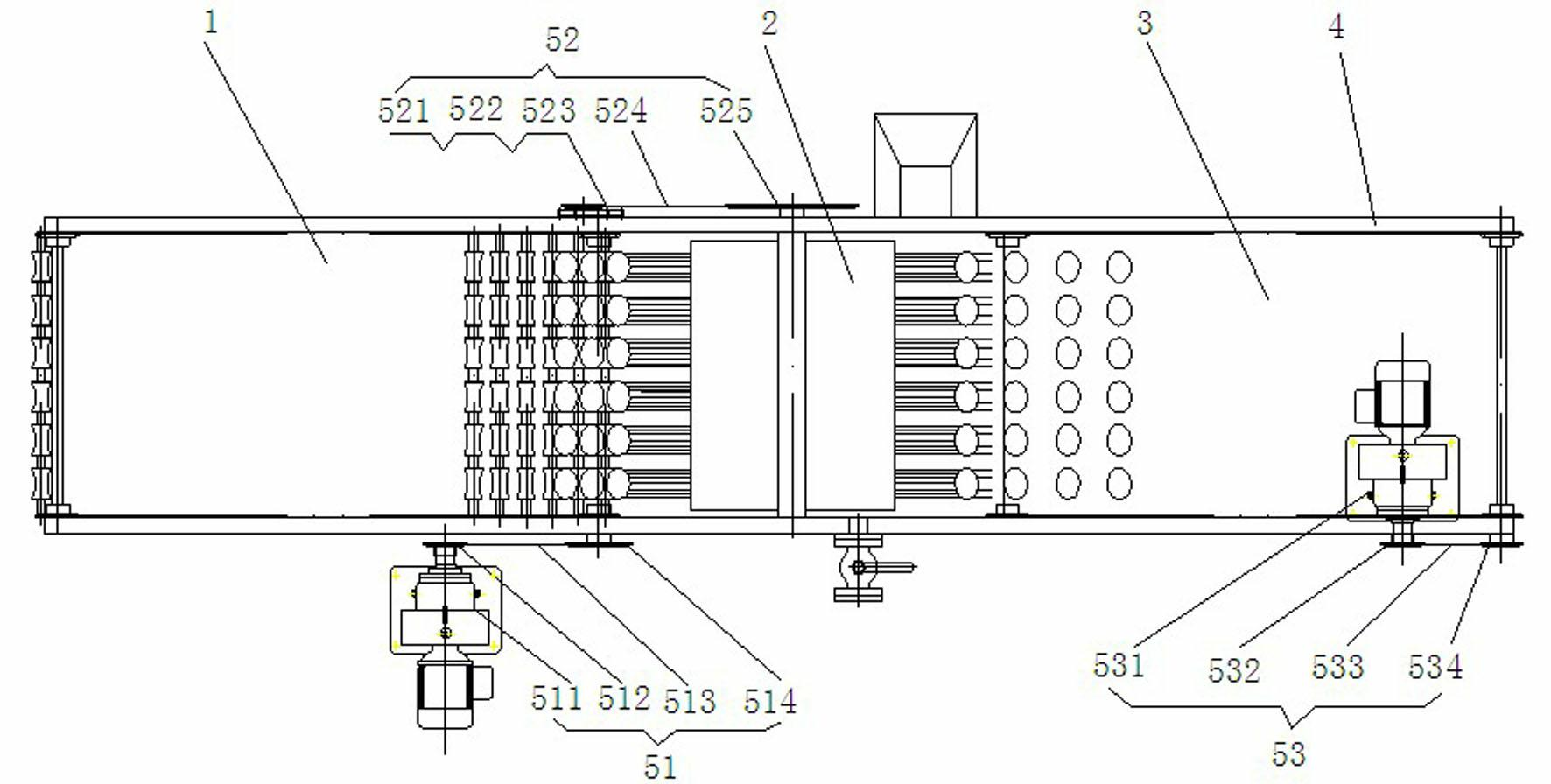

[0046] Referring to the accompanying drawings, a dial-type egg waxing machine of the present invention is characterized in that it includes an egg feeding device 1, a waxing device 2, an egg unloading device 3, a frame 4 and a power transmission device connected in sequence,

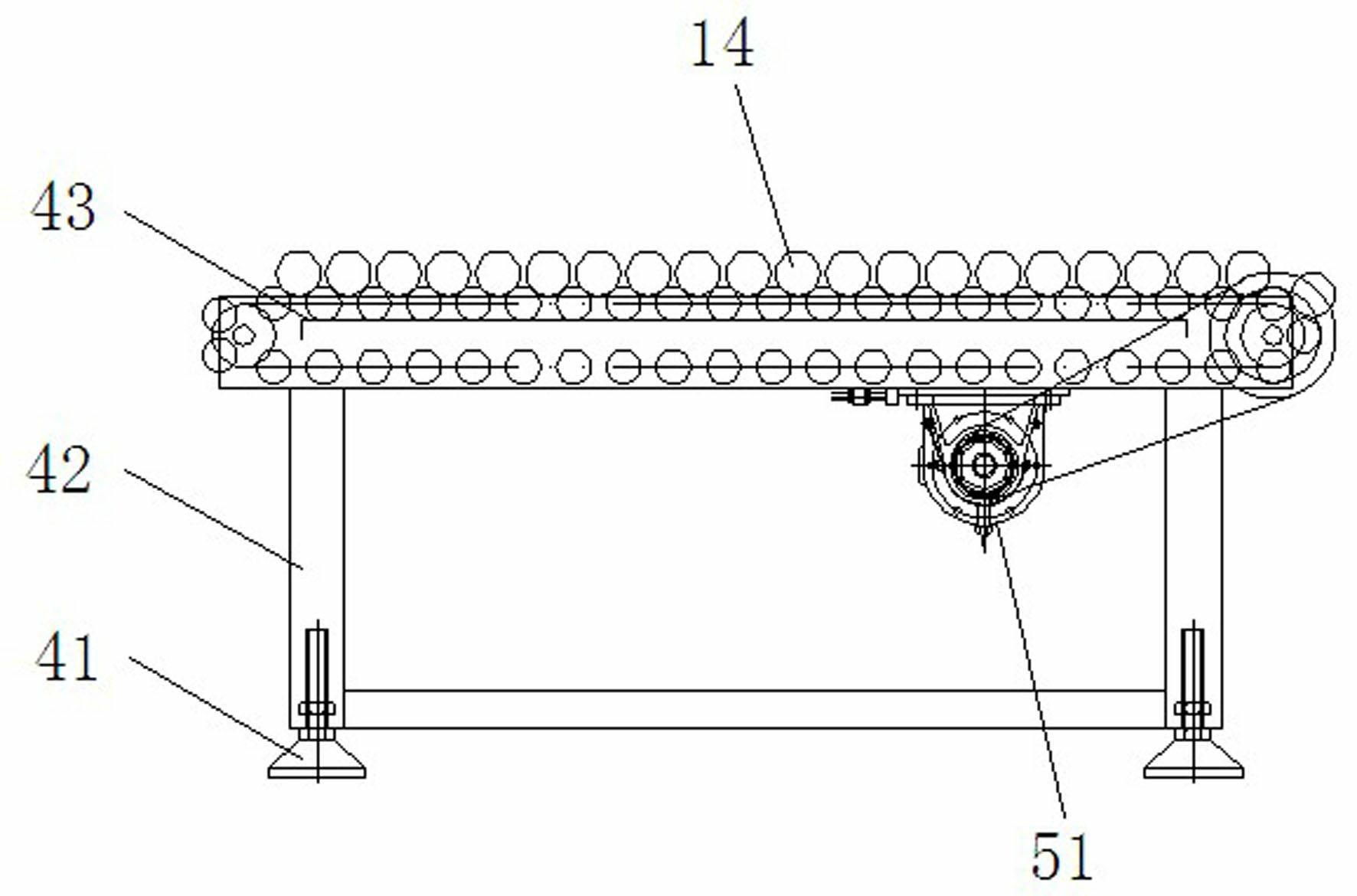

[0047] The egg conveying device 1 is a chain conveying device, mounted on the frame 4, including two chain conveying driving wheels 11 coaxially installed on both sides of the front of the egg conveying device 1, coaxially installed on the egg conveying Two chain-type conveying driven wheels 12 on both sides of the rear of the device 12, two chain-type conveying chains 13 engaged with it, and several egg-holding rollers 14 horizontally installed between the two chain-type conveying chains 13, each egg-holding roller Roller 14 comprises egg-holding roller main shaft 141 and several egg-holding rollers 142 that are rotatably sheathed on the egg-holding roller main shaft 141, and egg-holding roller 142 side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com