Alcohol production method

A production method and alcohol technology, which are applied in chemical instruments and methods, biofuels, organic chemistry and other directions, can solve the problems of low alcohol yield and high energy consumption, and achieve the advantages of improving ethanol yield, improving washing efficiency and saving energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

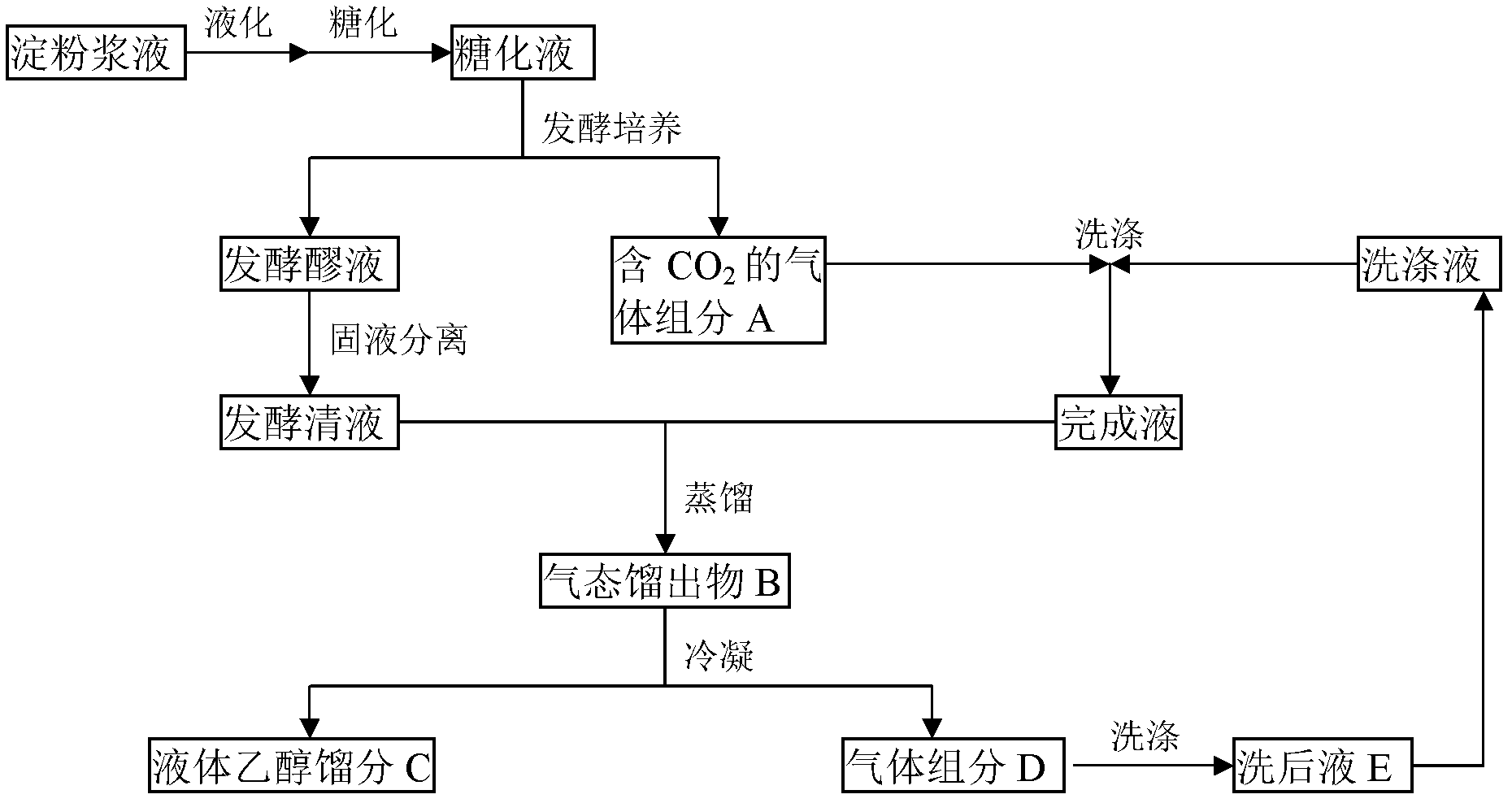

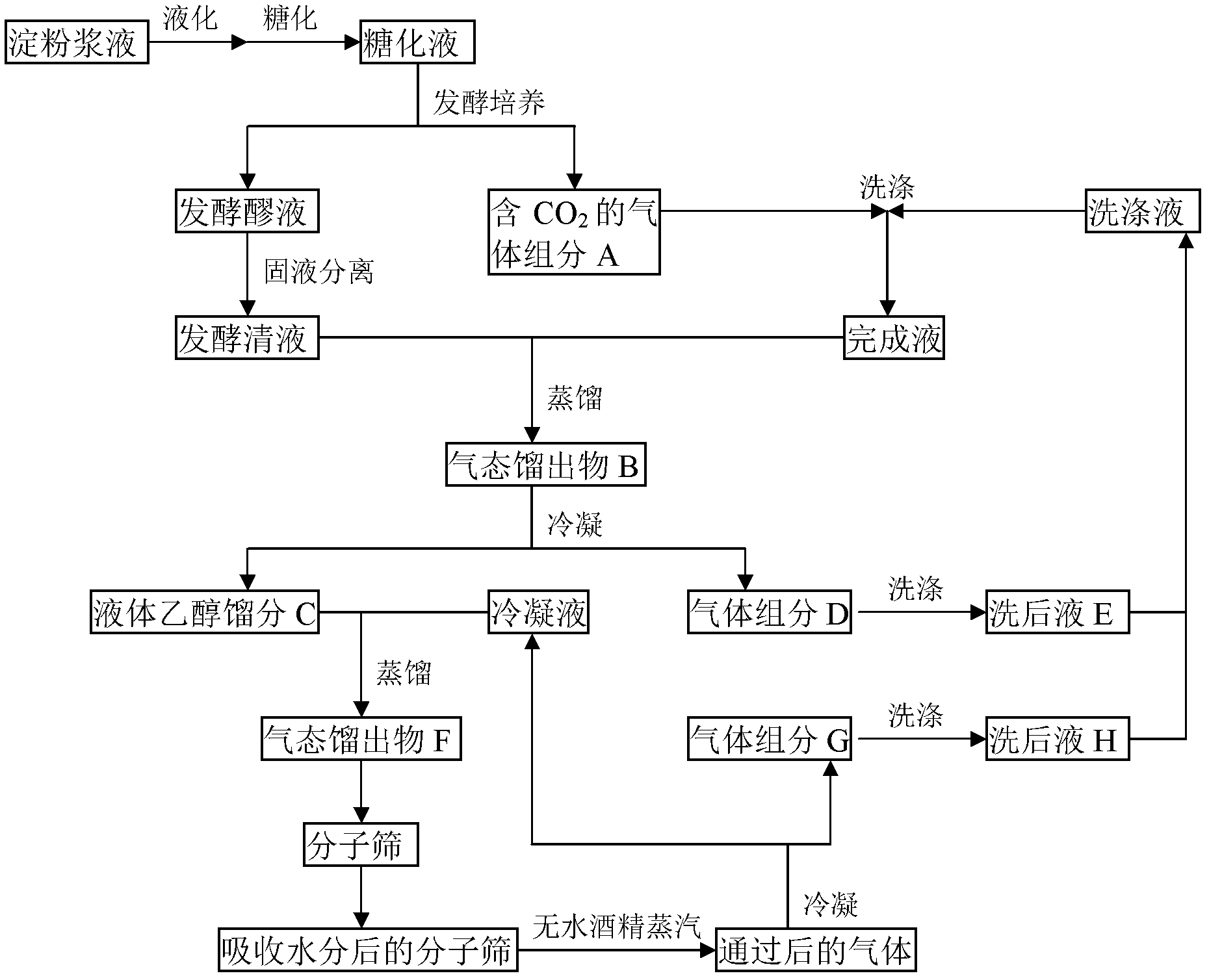

[0048] The first type, such as figure 1 As shown, the starch slurry is successively liquefied and saccharified, and the saccharification liquid obtained by saccharification is fermented and cultured to obtain CO-containing 2 Gas component A and fermentation mash; will contain CO 2 The gas component A is in contact with the scrubbing liquid for scrubbing to make CO 2 The ethanol in the gas component A is dissolved in the washing liquid to obtain the finished liquid; the fermentation mash is subjected to solid-liquid separation to obtain the fermentation clear liquid; the finished liquid and the fermentation clear liquid are distilled together to vaporize the ethanol therein, Obtain gaseous distillate B, condense gaseous distillate B to ethanol as a liquid, obtain liquid ethanol fraction C and gas component D; contact gas component D with water for washing, so that the gas component D Ethanol is dissolved in water to obtain liquid E after washing. The washing liquid is liquid E af...

Embodiment 1

[0061] use figure 1 The technological process of mixing starch material (corn flour) with water for beating, the obtained slurry is sequentially liquefied and saccharified, the saccharified liquid is fermented and cultivated, and the gas components (containing CO 2 The gas component A), and the CO contained during the fermentation process 2 The gas component A (the ethanol content is 0.84% by volume) is introduced from the bottom of the first gas scrubbing tower and discharged from the top of the first gas scrubbing tower. The scrubbing liquid is introduced from the top of the first gas scrubbing tower and The bottom of the scrubber is discharged, so that the CO 2 The gas component A is in countercurrent contact with the scrubbing liquid, containing CO 2 The volume ratio of the gas component A to the scrubbing liquid is 1:0.0024, the contact time is 5.1 seconds, the reflux ratio of the scrubbing tower is 10, and the finished liquid is obtained after washing.

[0062] The fermenta...

Embodiment 2

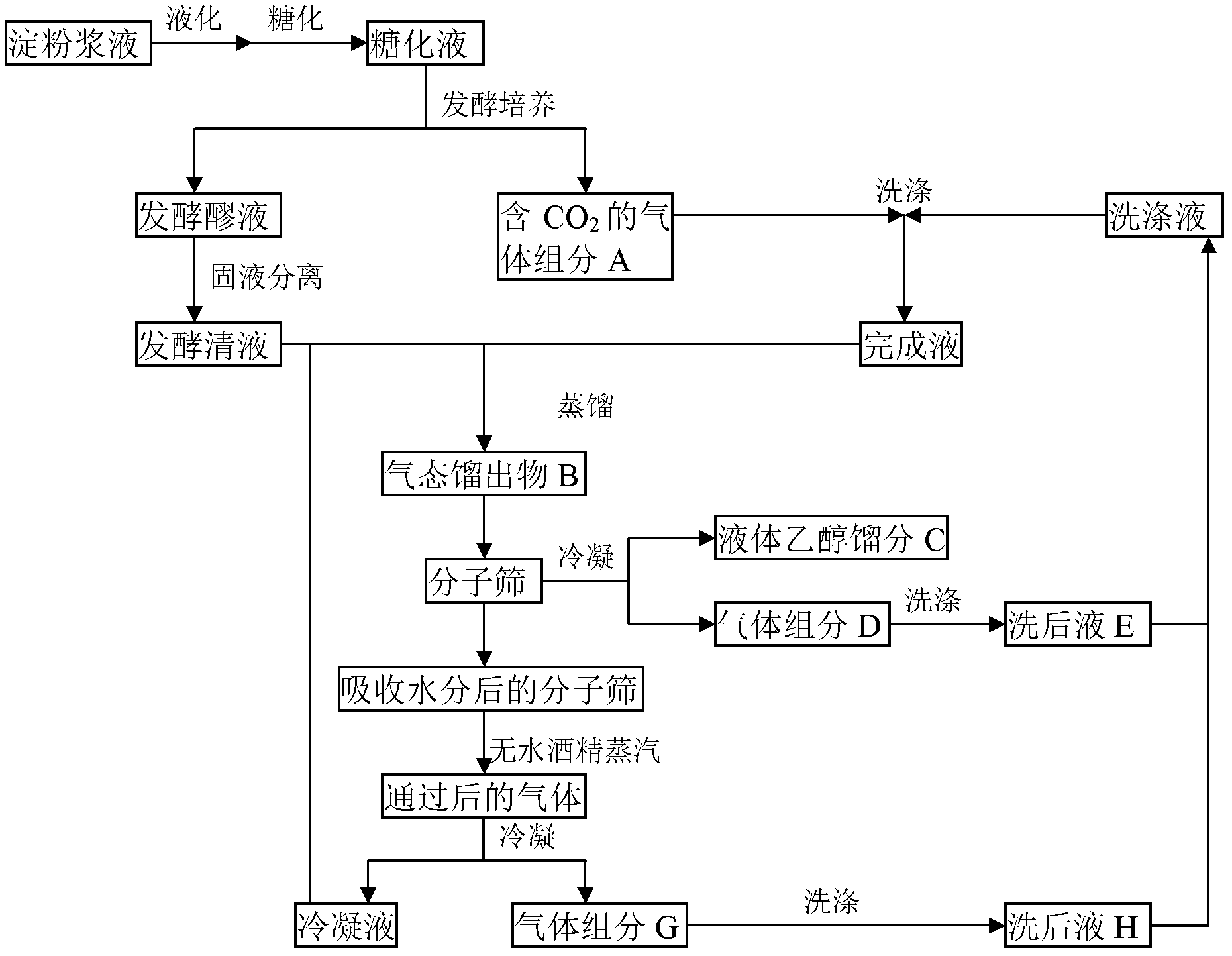

[0064] use figure 2 The technological process of mixing starch material (corn flour) with water for beating, the obtained slurry is sequentially liquefied and saccharified, the saccharified liquid is fermented and cultivated, and the gas components (containing CO 2 The gas component A), and the CO contained during the fermentation process 2 The gas component A (ethanol content is 1.25% by volume) is introduced from the bottom of the first gas scrubbing tower and discharged from the top of the first gas scrubbing tower, and the scrubbing liquid is introduced from the top of the first gas scrubbing tower, The bottom of the scrubber is discharged, so that the CO 2 The gas component A is in countercurrent contact with the scrubbing liquid, containing CO 2 The volume ratio of the gas component A to the scrubbing liquid is 1:0.0031, the contact time is 4.2 seconds, the reflux ratio of the scrubbing tower is 8, and the finished liquid is obtained after washing.

[0065] The fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com