Flame-retardant alkyd resin and preparation method thereof

The technology of alkyd resin and soybean oleic acid is applied in the field of coating and coating resin flame retardant alkyd resin. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

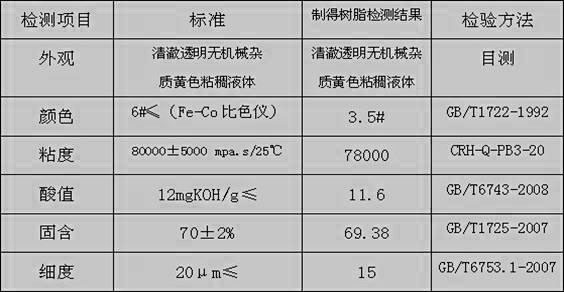

Embodiment 1

[0011] The flame retardant alkyd resin of the present embodiment, its raw material formula, by weight percentage, is made up of following components:

[0012] Soybean oleic acid 21.03%;

[0013] Pentaerythritol 10.36 %;

[0014] Tetrabromobisphenol A 6.6%;

[0015] Maleic anhydride 0.6%

[0016] Tetrabromophthalic anhydride 31.92%;

[0017] Color reducer 0.10%;

[0018] Antioxidant 0.10%;

[0020] For dilute solvents 26.29%;

[0021] Above-mentioned soybean oleic acid, pentaerythritol, tetrabromobisphenol A, maleic anhydride, tetrabromophthalic anhydride are all commercially available products;

[0022] The above-mentioned color reducing agent is hypophosphorous acid;

[0023] Above-mentioned antioxidant is triphenyl phosphite;

[0024] Above-mentioned dilute solvent is xylene;

[0025] The flame-retardant alkyd resin of this embodiment is to adopt the above-mentioned raw material formula and obtain through the following method preparati...

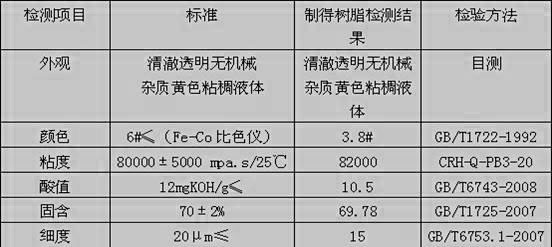

Embodiment 2

[0037] The alkyd resin for wood lacquer of the present embodiment, its raw material formula, by mass percentage, is made up of following components:

[0038] Soybean oleic acid 21.03%;

[0039] Pentaerythritol 10.36 %;

[0040] Tetrabromobisphenol A 6.6%;

[0041] Maleic anhydride 0.6%

[0042] Tetrabromophthalic anhydride 31.92%;

[0043] Color reducer 0.10%;

[0044] Antioxidant 0.10%;

[0045] Reflux xylene 3.00%;

[0046] For dilute solvents 26.29%;

[0047] Above-mentioned soybean oleic acid, pentaerythritol, tetrabromobisphenol A, maleic anhydride, tetrabromophthalic anhydride are all commercially available products;

[0048] The above-mentioned color reducing agent is hypophosphorous acid;

[0049] Above-mentioned antioxidant is triphenyl phosphite;

[0050] Above-mentioned dilute solvent is xylene;

[0051] The flame-retardant alkyd resin of this embodiment is to adopt the above-mentioned raw material formula and obtain through the following method preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com