Preparation method of galloyl konjac glucomannan

A technology of galloyl and mannan, which is applied in the field of preparation of gallokonjac glucomannan, and achieves the effects of wide application prospect, improvement of hydrosol viscosity and stability, and easy process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

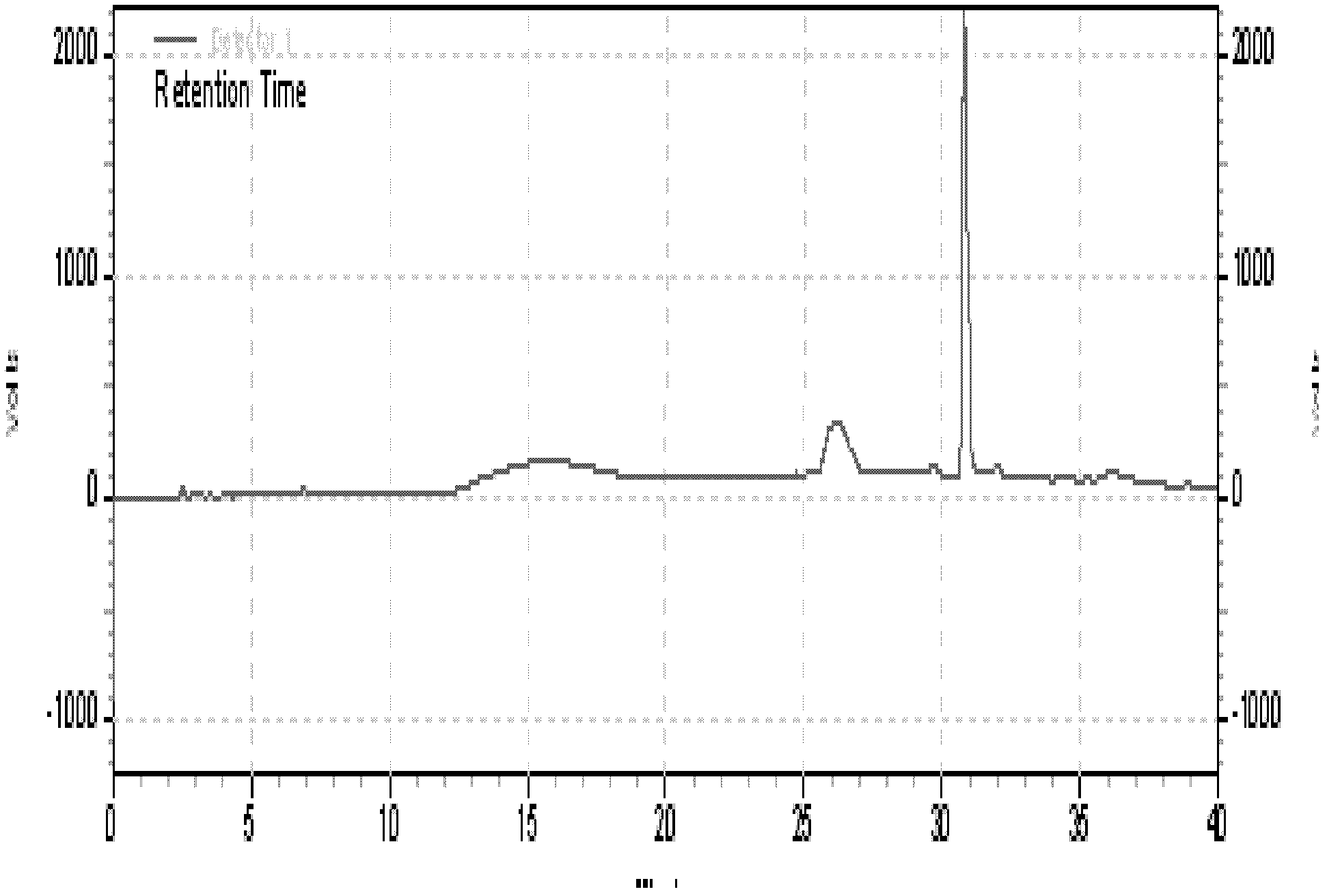

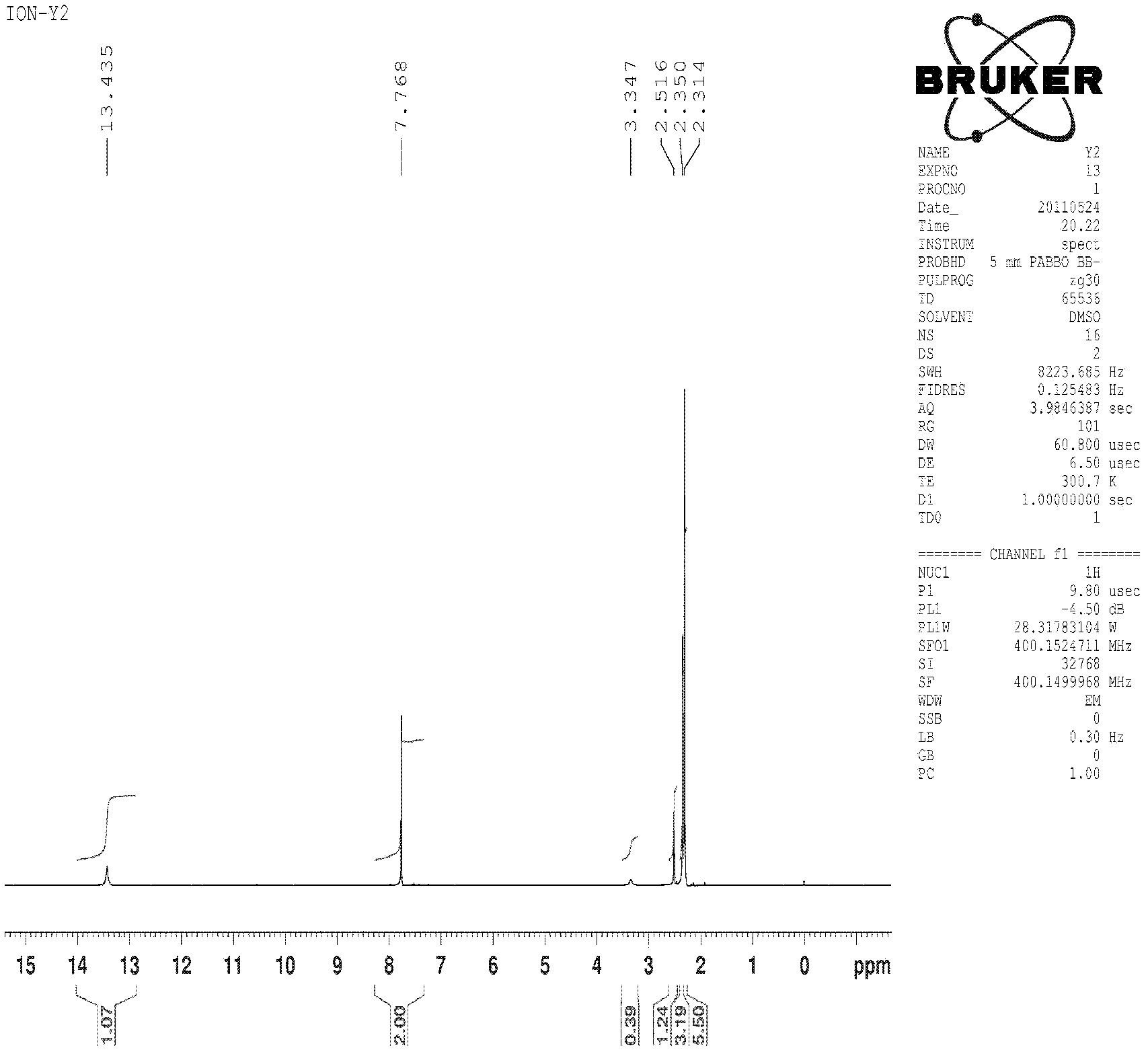

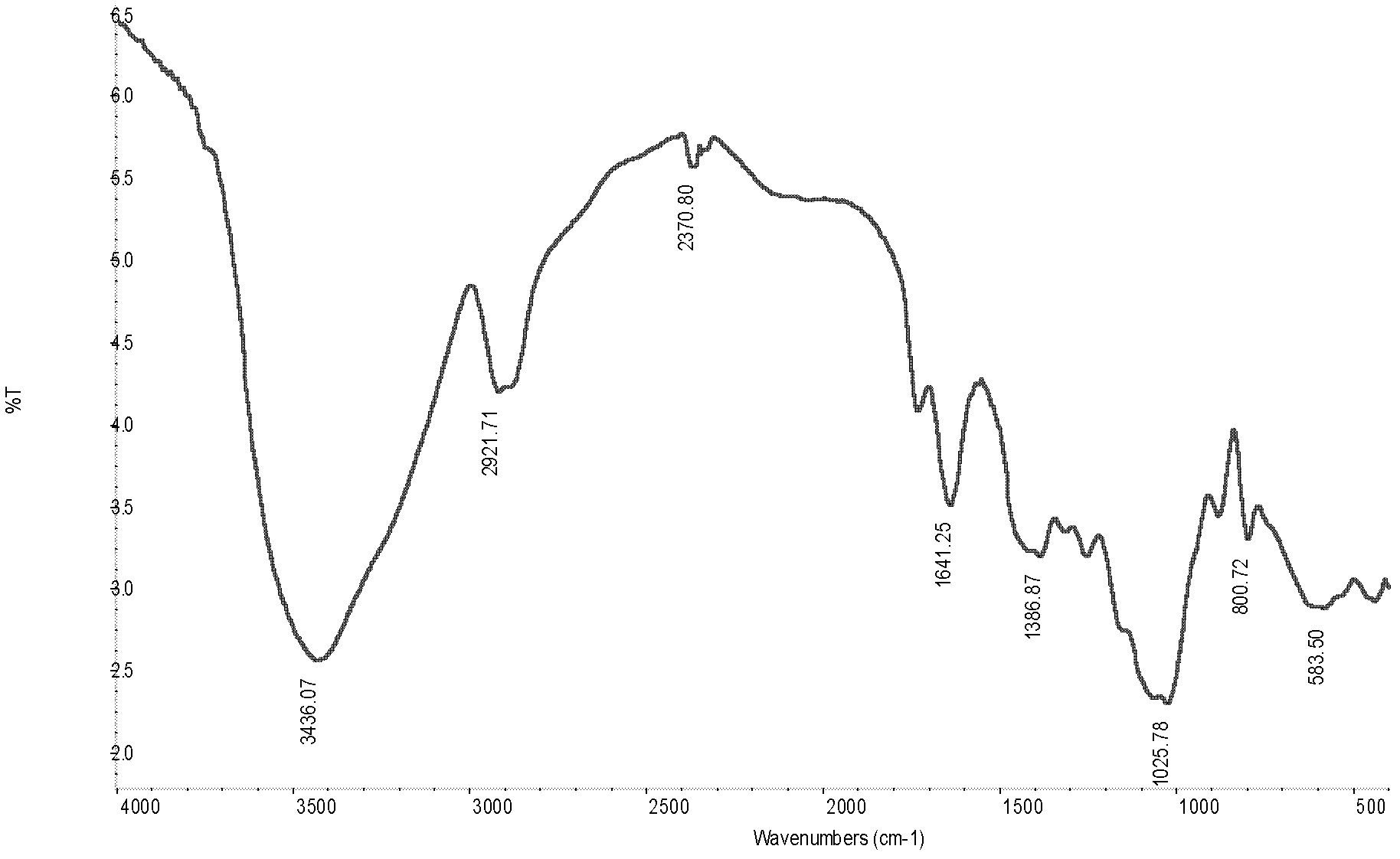

[0044] Embodiment 1: Preparation of galloyl konjac glucomannan

[0045] The implementation steps are as follows:

[0046] (A) Preparation of triacetyl gallic acid

[0047] Add gallic acid (30g, 0.177mol), acetic anhydride (67mL, 0.708mol) and anhydrous pyridine (57mL, 0.708mol) in a molar ratio of 1:4:4 into a 1000mL round-bottomed flask (ice bath), at a temperature of 25 Slowly stir for 12 hours under the condition of ℃, then add 620mL water, that is, 5 times the reaction volume of water to dilute, then add concentrated hydrochloric acid to adjust the pH value of the solution to 1, after that, precipitation occurs, filter with suction, and the obtained solid is washed with a small amount of cold water , dried at a temperature of 55-65° C. to constant weight to obtain 46.46 g of a white powdery solid, identified by the method described in this manual, and the white powdery solid was triacetyl gallic acid. The yield is 87% based on the amount of raw materials used and the amoun...

Embodiment 2

[0055] Embodiment 2: Preparation of galloyl konjac glucomannan

[0056] This example is carried out in the same manner as Example 1, except that in step (A), the molar ratio of gallic acid, acetic anhydride and anhydrous pyridine is adjusted to 1:2:6; step B) the prepared triacetyl gall The mol ratio of acid and thionyl chloride is 1: 2; in step (C), the mass ratio of its konjac glucomannan and triacetyl galloyl chloride is 1: 4; in step (D), step (C) The prepared triacetylgalloyl konjac glucomannan was dissolved in a saturated sodium acetate solution in absolute ethanol at a ratio of 25 mL / g.

[0057] Calculated according to the amount of raw materials used in this embodiment and the amount of the product galloyl konjac glucomannan, the total yield is 56%. The hydrosol viscosity and stability of the galloyl konjac glucomannan prepared in this example were measured by the method described in this specification, and the results were 1.0×10 -3 Pa·s and 5 days.

Embodiment 3

[0058] Example 3: Preparation of galloyl konjac glucomannan

[0059] This example is carried out in the same manner as Example 1, except that in step (A), the molar ratio of gallic acid, acetic anhydride and anhydrous pyridine is adjusted to 1:6:2; the triacetyl prepared in step (B) The mol ratio of gallic acid and sulfur oxychloride is 1: 5; In step (C), the mass ratio of its konjac glucomannan and triacetyl galloyl chloride is 1: 2; In step (D), step (C ) prepared triacetylgalloyl konjac glucomannan was dissolved in saturated sodium acetate in absolute ethanol solution according to the ratio of 60mL / g.

[0060] Calculated according to the amount of raw materials used in this example and the amount of the product galloyl konjac glucomannan, the total yield is 62%. The hydrosol viscosity and stability of the galloyl konjac glucomannan prepared in this example were measured by the method described in this specification, and the results were 0.7×10 -3 Pa·s and 5 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com