Processing method of flexible nozzle thin-wall dual-spherical reinforcing part and device thereof

A flexible nozzle and processing method technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor surface roughness, large vibration of parts, large deformation of parts, etc., and achieves high processing accuracy and saving. Raw materials, the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] For a flexible nozzle reinforcement, the size of the inner arc is SR159.15mm, the size of the outer arc is SR161.75mm, the wall thickness is 2.6mm, the material is 30CrMnSiA high-strength steel, the tensile strength after quenching and tempering is 1000MPa, the processing control The process is as follows:

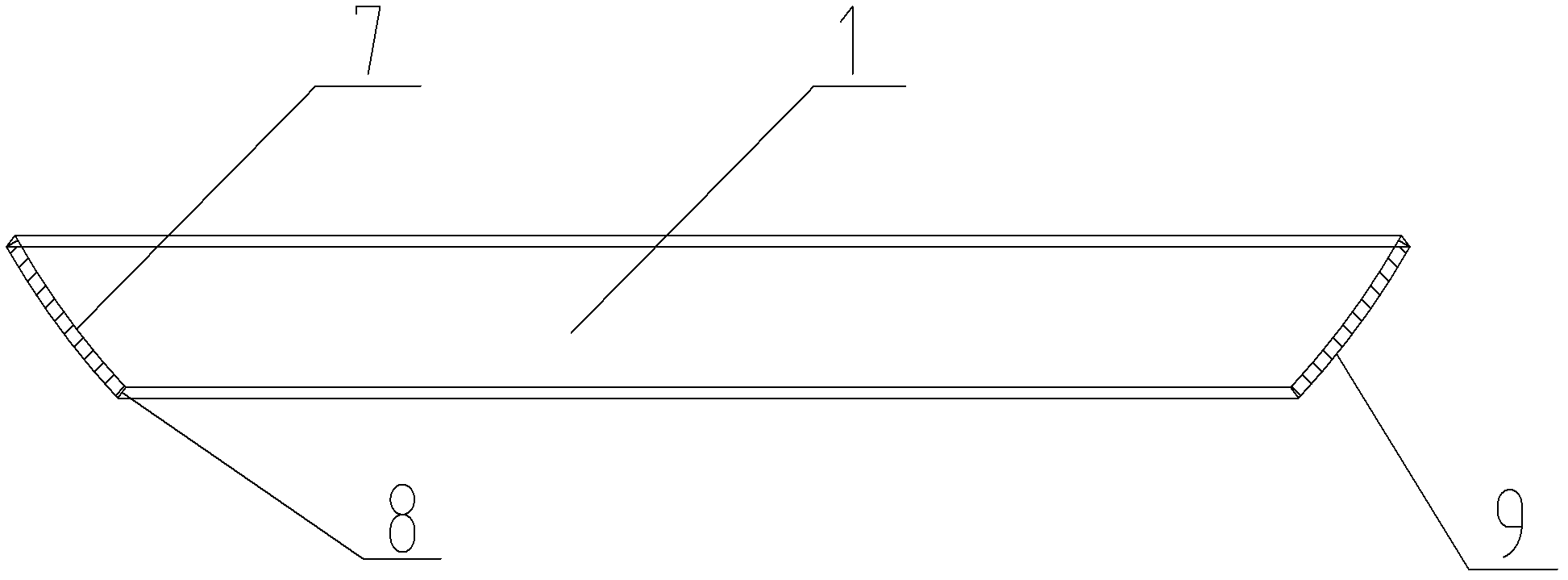

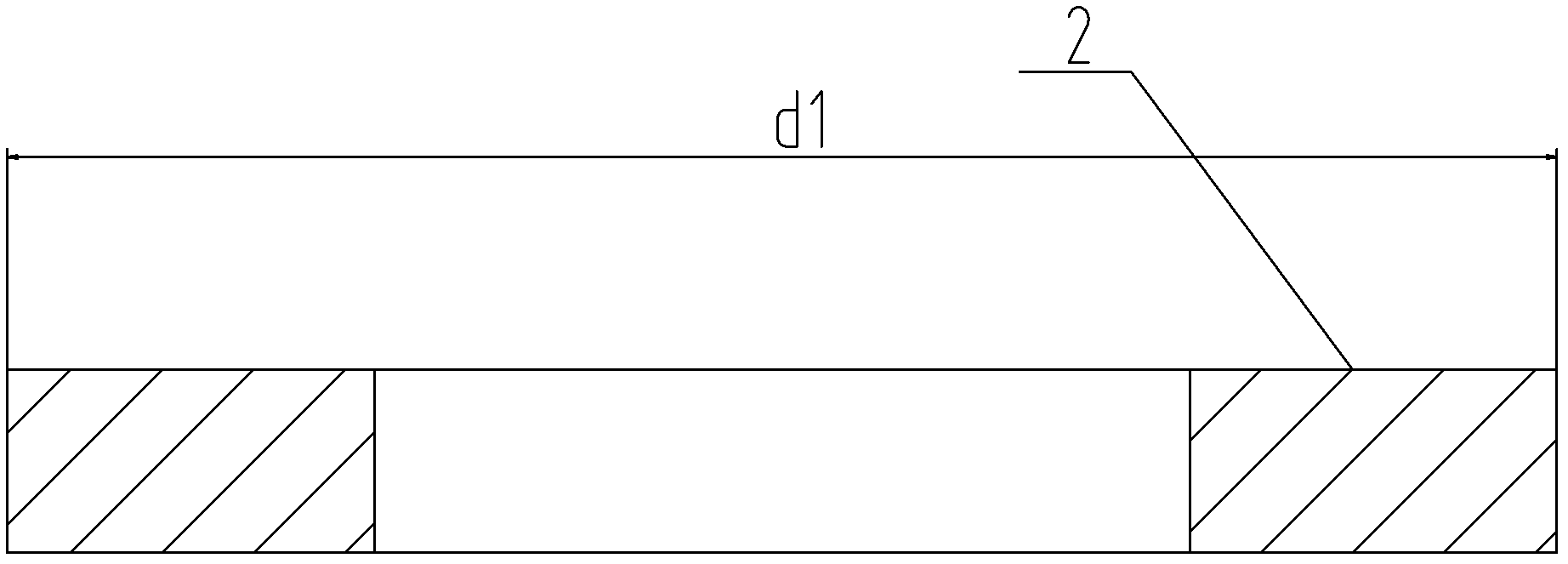

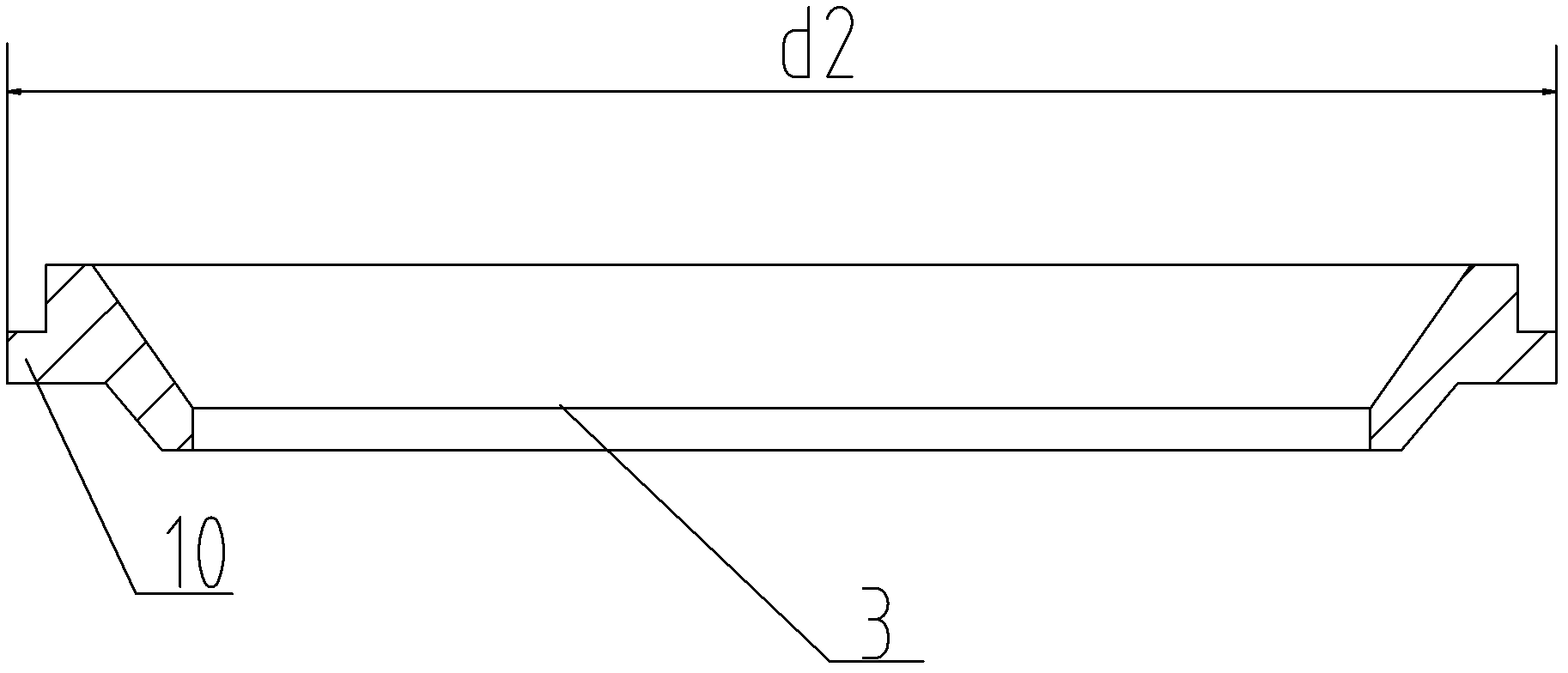

[0049] 1) Forging blank preparation: according to figure 1 The maximum external dimension of the final product flexible nozzle thin-walled double-spherical reinforcement 1 is shown, with a machining allowance of 5 mm on one side, and a ring forging blank 2 is prepared by a conventional forging process. Its external structure is as follows figure 2 shown;

[0050] 2) Rough turning: use the lathe chuck to clamp the outer circle d1 surface of the ring forging blank 2, and remove the surface defects and most of the machining allowance of the ring forging blank 2 by turning, so as to ensure the hardenability and mechanical processing of the subsequent quenching and tem...

Embodiment 2

[0059] For a flexible nozzle reinforcement, the size of the inner arc is SR179.15mm, the size of the outer arc is SR181.75mm, the wall thickness is 2.6mm, the material is 30CrMnSiA high-strength steel, the tensile strength after quenching and tempering is 1100MPa, the processing control The process is as follows:

[0060] 1) Forging blank preparation: according to figure 1 The maximum external dimension of the final product flexible nozzle thin-walled double-spherical reinforced part 1 is shown, with a machining allowance of 10 mm on one side, and a ring forging blank 2 is prepared by a conventional forging process, and its external structure is as follows figure 2 shown;

[0061] 2) Rough turning: use the lathe chuck to clamp the outer circle d1 surface of the ring forging blank 2, and remove the surface defects and most of the machining allowance of the ring forging blank 2 by turning, so as to ensure the hardenability and mechanical processing of the subsequent quenching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Material hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com