Oxygen reduction non-noble metal catalyst and preparation method thereof

A non-precious metal, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of lack of resources and high cost of Pt/C catalysts, achieve high graphitization degree, excellent oxygen Reduction catalytic performance, the effect of excellent oxygen reduction catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

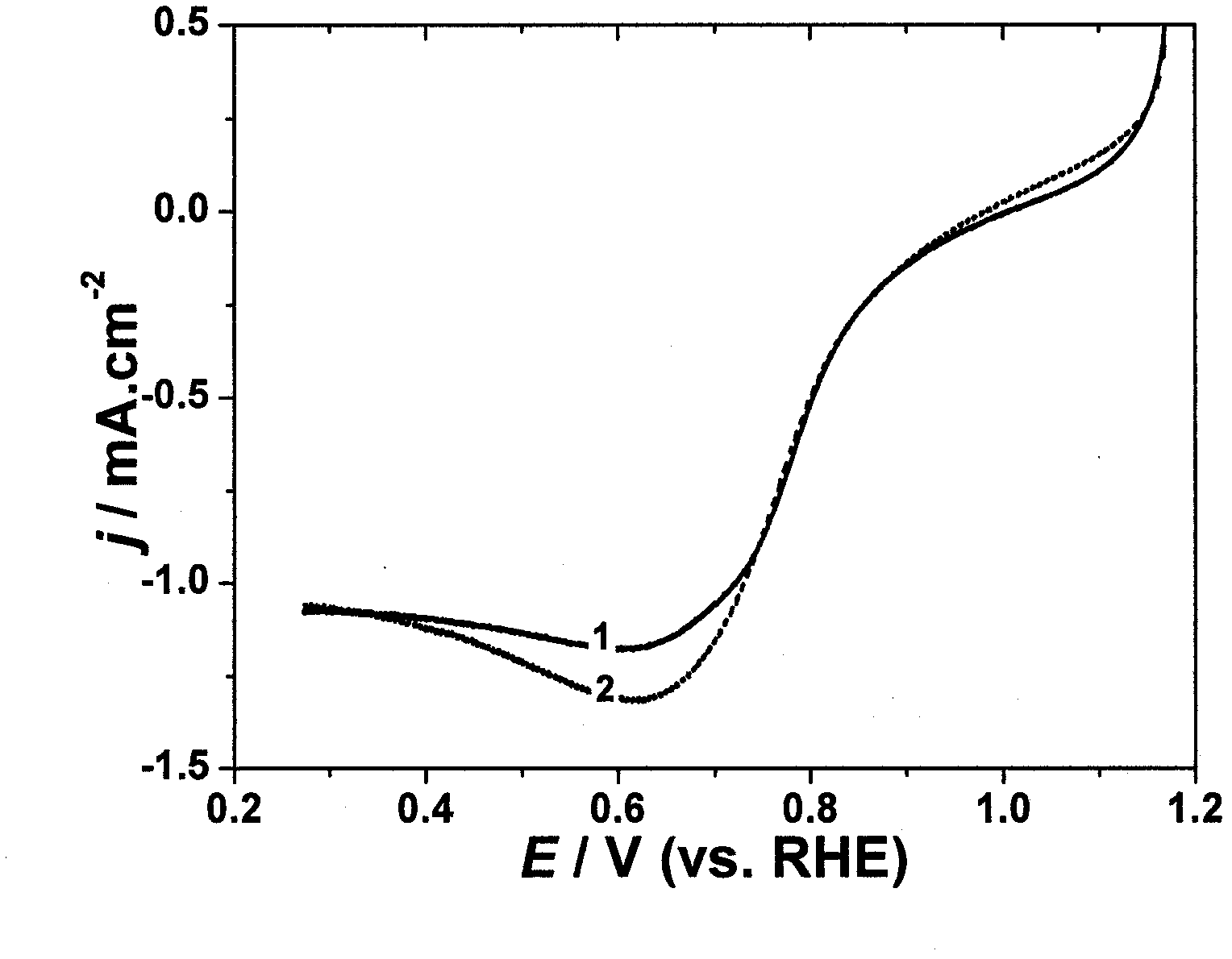

Image

Examples

Embodiment 1

[0032] An oxygen-reducing non-noble metal catalyst and a preparation method thereof, the specific method steps comprising:

[0033] (1) Preparation of montmorillonite suspension for aniline intercalation

[0034] Weigh montmorillonite and aniline according to the mass ratio of montmorillonite: aniline of 1:1, first disperse montmorillonite in deionized water, and ultrasonically stir for 5 hours to form a montmorillonite suspension with a mass concentration of 0.05 g / ml Measure ethanol by montmorillonite suspension: the volume ratio of ethanol is 1: 0.5, dissolve aniline in ethanol, and join in the above-mentioned montmorillonite suspension, stir 30 hours at 20 ℃, form the montmorillonite intercalation of aniline Desoil suspension.

[0035] (2) Interlayer polymerization of aniline

[0036]The montmorillonite suspension of the aniline intercalation obtained by step (1): the volume ratio of sulfuric acid solution 1: 0.3 measures sulfuric acid solution, wherein the concentration...

Embodiment 2

[0045] An oxygen-reducing non-noble metal catalyst and a preparation method thereof, the specific method steps comprising:

[0046] (1) Preparation of kaolin suspension for pyrrole intercalation

[0047] It is 1: 4 to weigh kaolin and pyrrole by kaolin: the mass ratio of pyrrole, first kaolin is dispersed in deionized water, and ultrasonic stirring 8 hours forms the kaolin suspension that mass concentration is 0.1 g / ml; Press kaolin suspension: acetone Acetone was measured at a volume ratio of 1:1, pyrrole was dissolved in acetone, and added to the above kaolin suspension, stirred at 60°C for 10 hours to form a pyrrole-intercalated kaolin suspension.

[0048] (2) Interlayer polymerization of pyrrole

[0049] The kaolin suspension of pyrrole intercalation obtained by step (1): the volume ratio of hydrochloric acid solution 1: 0.5 measures hydrochloric acid solution, wherein the concentration of hydrochloric acid solution is 0.5 mole / liter; by pyrrole: the mass ratio of hydroge...

Embodiment 3

[0055] An oxygen-reducing non-noble metal catalyst and a preparation method thereof, the specific method steps comprising:

[0056] (1) Preparation of hydrotalcite suspension for aniline intercalation

[0057] Weigh hydrotalcite and aniline according to the mass ratio of hydrotalcite: aniline of 1:0.1, first disperse the hydrotalcite in deionized water, and stir ultrasonically for 3 hours to form a hydrotalcite suspension with a mass concentration of 0.01 g / ml; The volume ratio of liquid: acetonitrile is 1:0.3. Measure acetonitrile, dissolve aniline in acetonitrile, and add it to the above hydrotalcite suspension, stir at 10°C for 40 hours to form an aniline-intercalated hydrotalcite suspension.

[0058] (2) Interlayer polymerization of aniline

[0059] The hydrotalcite suspension of the aniline intercalation obtained by step (1): the volume ratio of sulfuric acid solution 1: 0.1 measures sulfuric acid solution, wherein the concentration of sulfuric acid solution is 1.5 mol / l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com