Polarization and birefringence measuring system

A measurement system and birefringence technology, applied in the field of polarization and birefringence measurement systems, can solve the problems affecting the performance of the 193nm exposure optical system, short wavelength, and difficulty in space and time for fast and accurate measurement, so as to suppress noise and improve measurement accuracy. , the effect of avoiding nonlinear errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

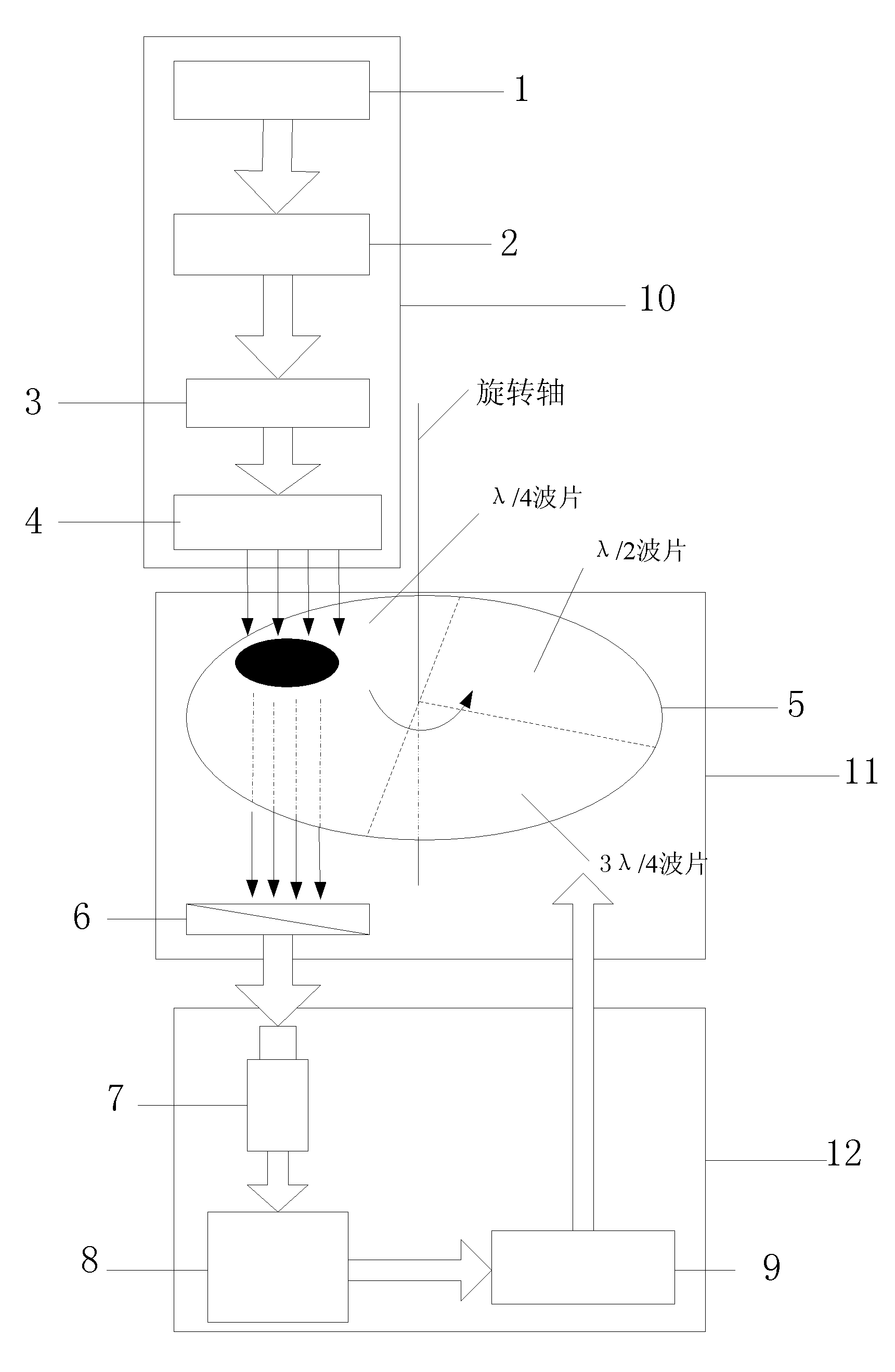

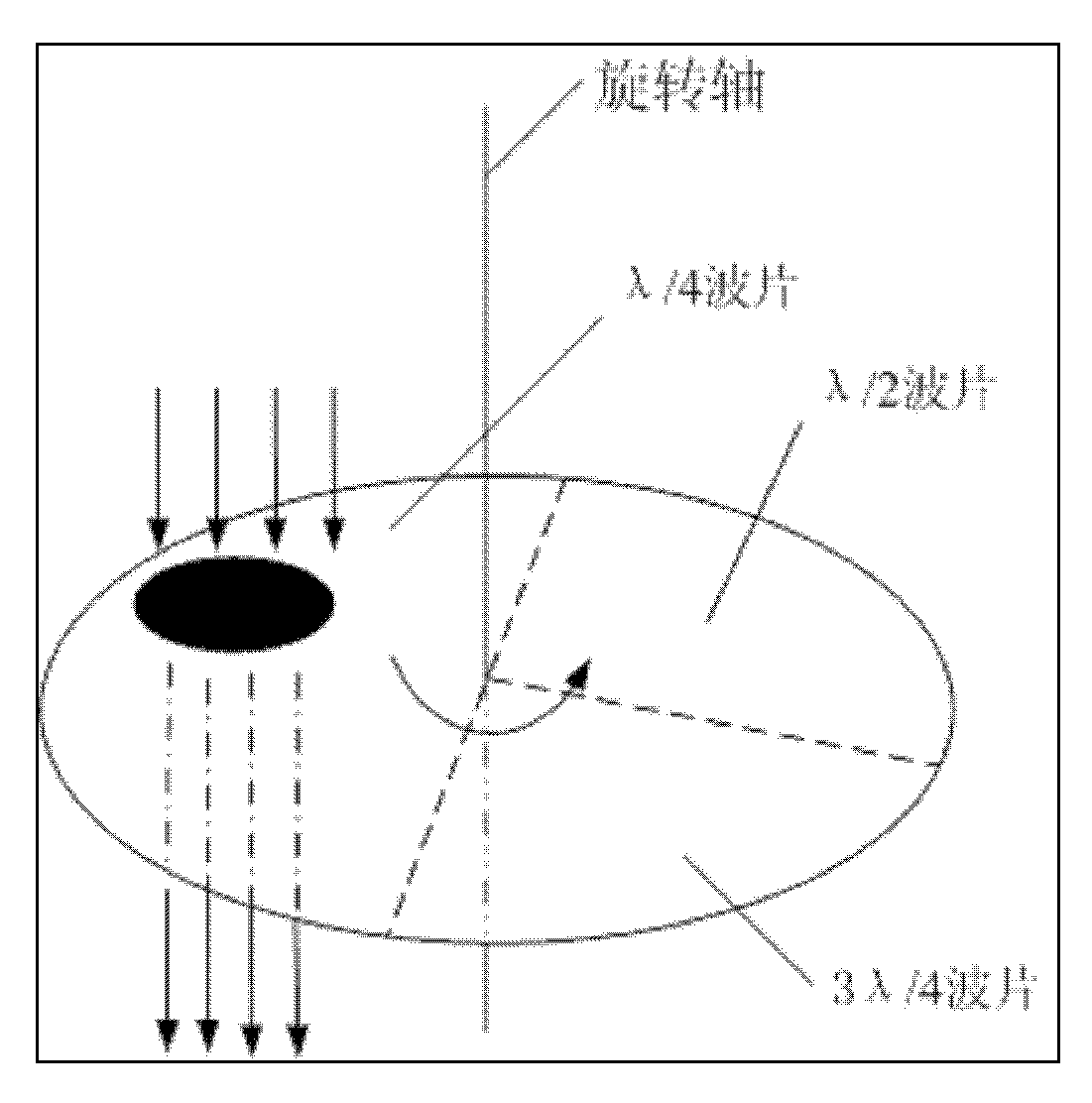

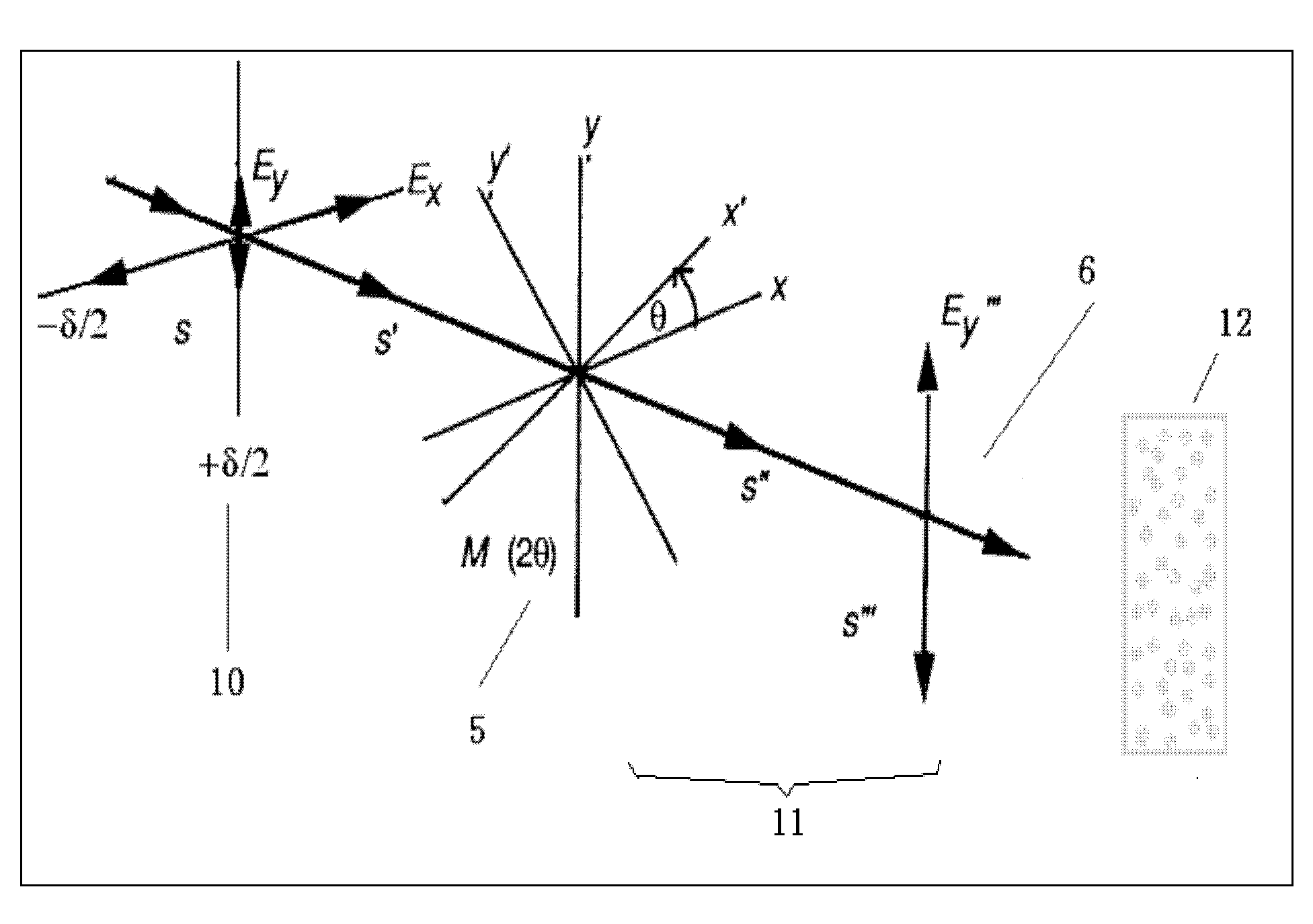

[0019] figure 1 It is a schematic diagram of the measurement principle of a polarization and birefringence measurement system, including a light source module 10, an optical signal modulation module 11, and a data acquisition and processing module 12. The light source module 10 includes a light source 1, a collimating beam expander system 2, and a polarizer 3 , the sample to be tested 4; the optical signal modulation module 11 includes a multi-stage phase difference coaxial wave plate 5 and a polarizer 6; the data acquisition and processing module 12 includes a light intensity detector 7, a computer 8 and a stepping motor 9. Such as figure 1 As shown, the light source 1 is an ArF laser with a wavelength of 193.368nm. The light emitted by the ArF laser passes through the collimator beam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com