System and method for detecting divided ring belts of ultra-large-aperture convex hyperboloidal mirror

A super-large-diameter, hyperboloid mirror technology, applied to measuring devices, instruments, and optical devices, can solve problems such as high cost, high material uniformity, and difficulty in manufacturing auxiliary components, so as to reduce testing costs and avoid harsh requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

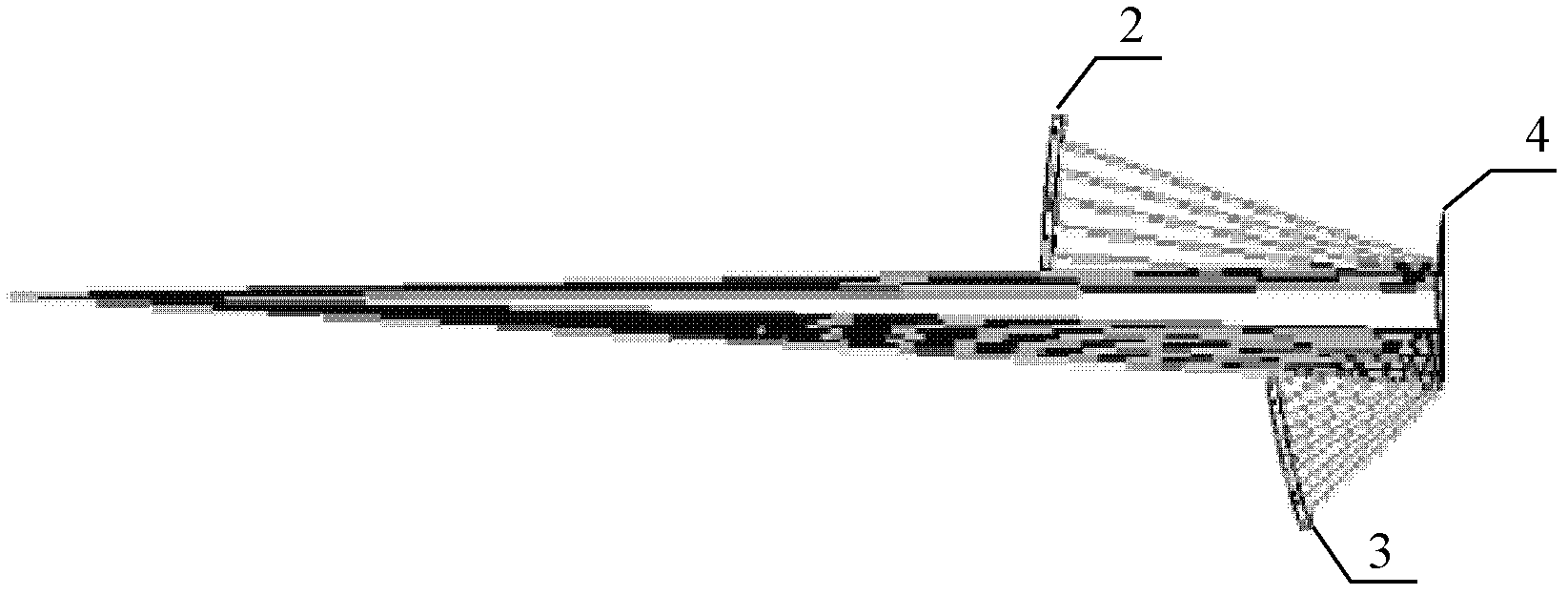

[0028] figure 1 As shown, a kind of ultra-large-diameter convex hyperboloid mirror sub-ring detection system of the present embodiment includes a phase shift interferometer 1, two Hindle spherical mirrors 2 and 3, a measured super-large-diameter convex hyperboloid mirror 4 and a computer system 5 , wherein the computer system 5 is connected with the phase-shift interferometer 1, a Hindle spherical mirror 2 is used to realize the sub-aperture detection that the center of the convex hyperboloid mirror is blocked to an inner ring, and another Hindle spherical mirror 3 is used to realize the convex For the sub-aperture detection of a ring band inside the hyperboloid mirror, the phase data of the corresponding two sub-apertures is extracted through the phase-shift interferometer data processing software installed on the computer system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com