Industrial furnace for non-ferrous metal smelting

A non-ferrous metal, industrial furnace technology, applied in furnaces, furnace components, preheating costs, etc., to avoid a large amount of loss, avoid damage, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

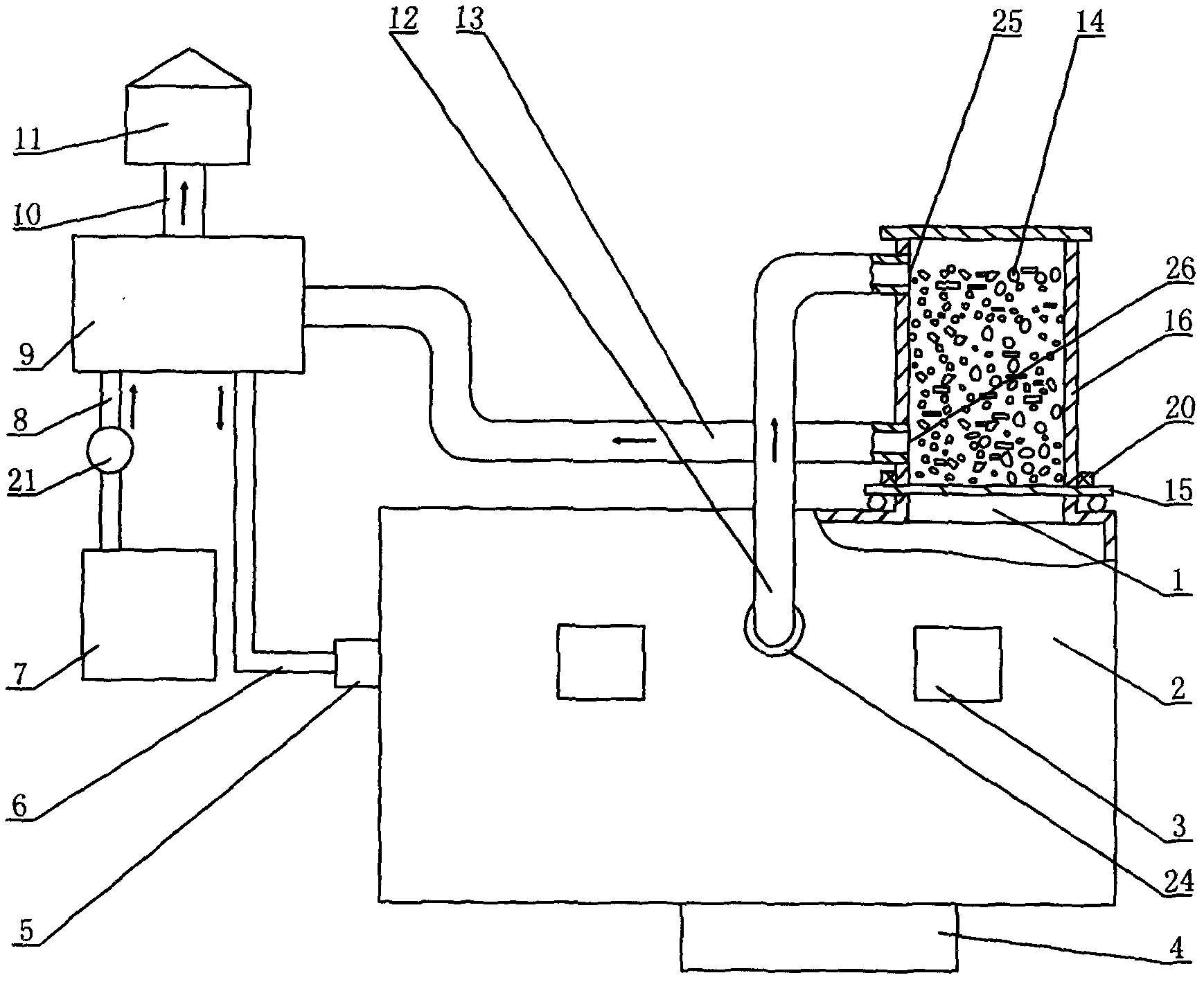

[0038] Embodiment one: if figure 1 As shown, the present invention mainly consists of a furnace 2, a vertical feed cylinder 16 connected to the furnace feed port 1, a fuel device 5 connected to the left end wall of the furnace 2, a mixer 4 positioned at the bottom of the furnace 2, and a furnace mounted on the furnace. 2 outside the heat exchange system; the furnace feed inlet 1 is located at the right end of the furnace top of the furnace 2, and two furnace doors 3 slightly higher than the liquid level of the charge 14 in the furnace are formed on the front side wall of the furnace 2. A furnace gas outlet 24 is formed on the front side wall in the middle of the door 3; Gas outlet 26; the heat exchange system is mainly composed of heat exchanger 9, fan 7, vertical feed cylinder 16, low temperature air pipeline 8, high temperature air pipeline 6, first stage furnace gas pipeline 12, second stage The furnace gas pipeline 13 is formed, the low-temperature air pipeline 8 is conn...

Embodiment 2

[0042] Embodiment two: if figure 2 As shown, the present invention mainly consists of a furnace 2, a vertical feed cylinder 16 connected to the furnace feed port 1, a fuel device 5 connected to the left end wall of the furnace 2, a mixer 4 positioned at the bottom of the furnace 2, and a furnace mounted on the furnace. 2 outside the heat exchange system; the furnace feed inlet 1 is located at the right end of the furnace top of the furnace 2, and two furnace doors 3 slightly higher than the liquid level of the charge 14 in the furnace are formed on the front side wall of the furnace 2. A furnace gas outlet 24 is formed on the front side wall in the middle of the door 3; Gas outlet 26; the heat exchange system is mainly composed of heat exchanger 9, fan 7, vertical feed cylinder 16, low temperature air pipeline 8, high temperature air pipeline 6, first stage furnace gas pipeline 12, second stage The furnace gas pipeline 13 is formed, the low-temperature air pipeline 8 is conn...

Embodiment 3

[0046] Embodiment three: as image 3 As shown, the present invention mainly consists of a furnace 2, an oblique feeding cylinder 17 connected to the furnace feed port 1, a fuel device 5 connected to the left end wall of the furnace 2, a mixer 4 positioned at the bottom of the furnace 2, installed on the The heat exchange system outside the furnace 2 is composed of; the furnace feed inlet 1 is located at the right end of the furnace roof of the furnace 2, and two furnace doors 3 slightly higher than the liquid level of the charge 14 in the furnace are formed on the front side wall of the furnace 2. Furnace furnace gas outlet 24 is shaped on the front side wall in the middle of furnace door 3; Barrel furnace gas outlet 26; the heat exchange system is mainly composed of heat exchanger 9, fan 7, oblique feeding cylinder 17, low temperature air pipeline 8, high temperature air pipeline 6, first stage furnace gas pipeline 12 , The second-stage furnace gas pipeline 13 is formed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com