Inflatable-seal-type cross-flow drying oven with dual drying cars

A technology of inflatable sealing and inflatable sealing ring, which is applied in drying, drying machine, drying gas arrangement and other directions, can solve the problem of affecting the efficiency of treatment process or process, the difficulty of moving and evaporating the moisture of internal materials, and easily polluting the interior of the equipment. Air outlet device and other issues, to achieve the effect of saving drying cost, compact structure and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

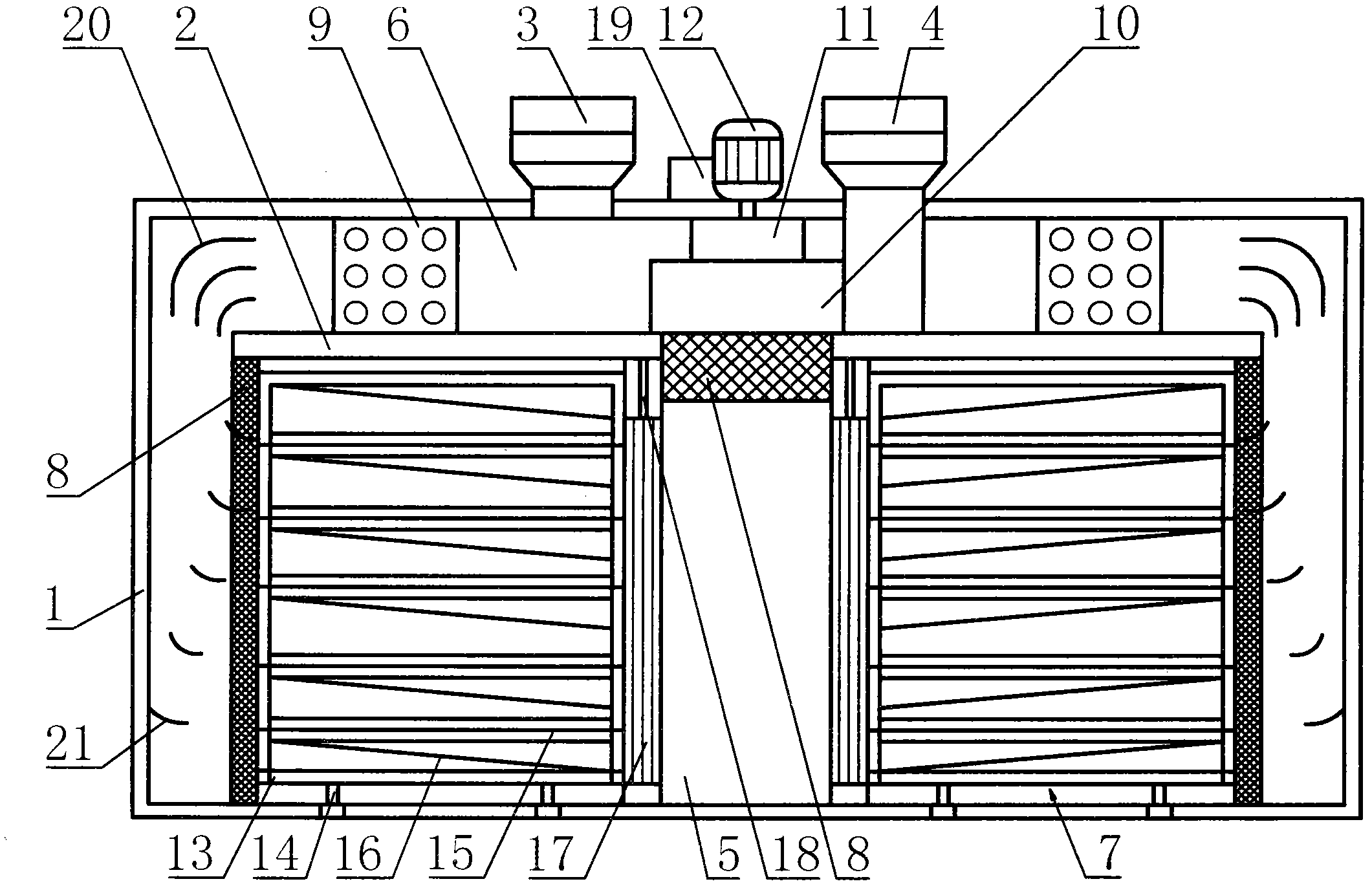

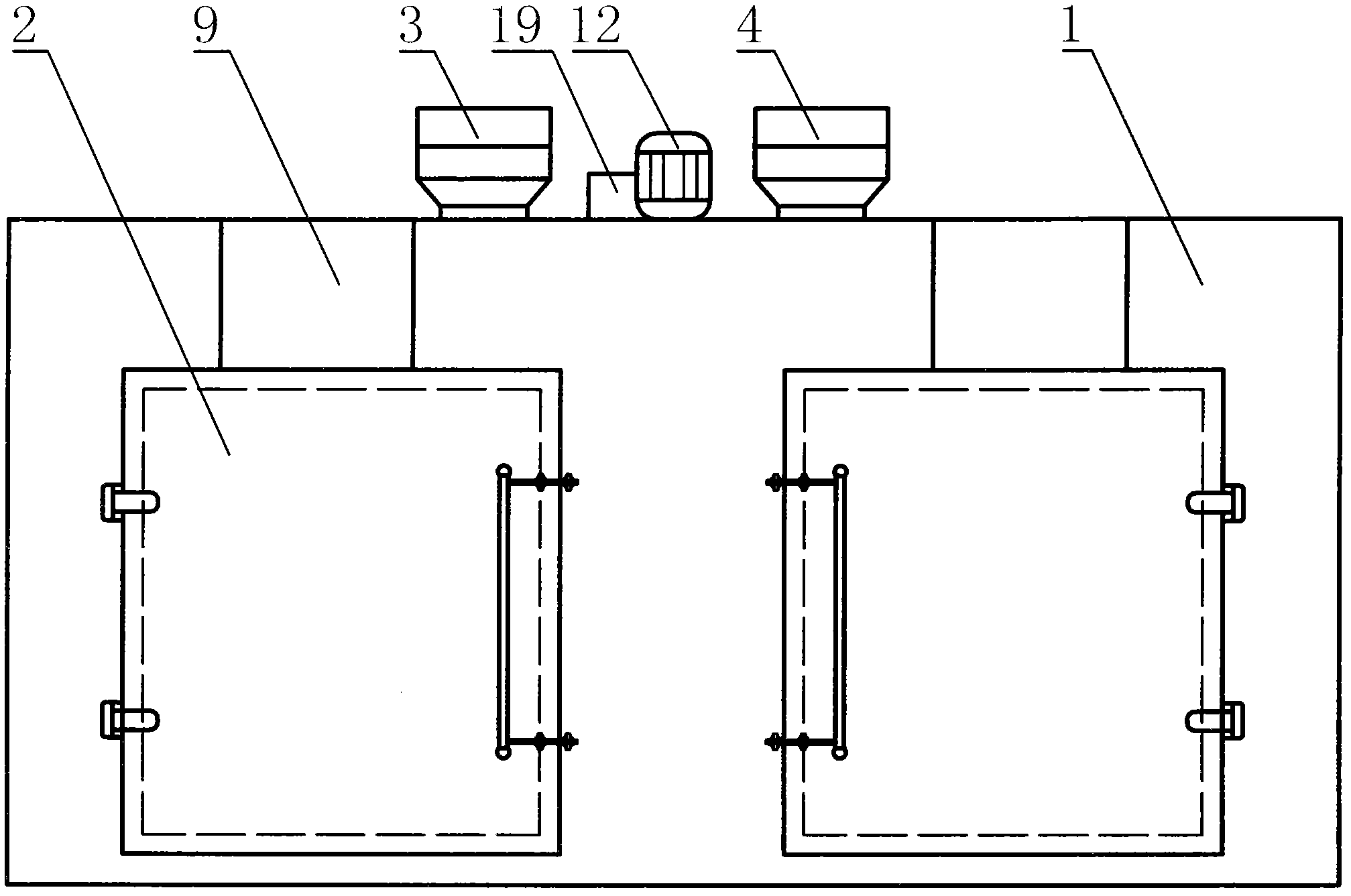

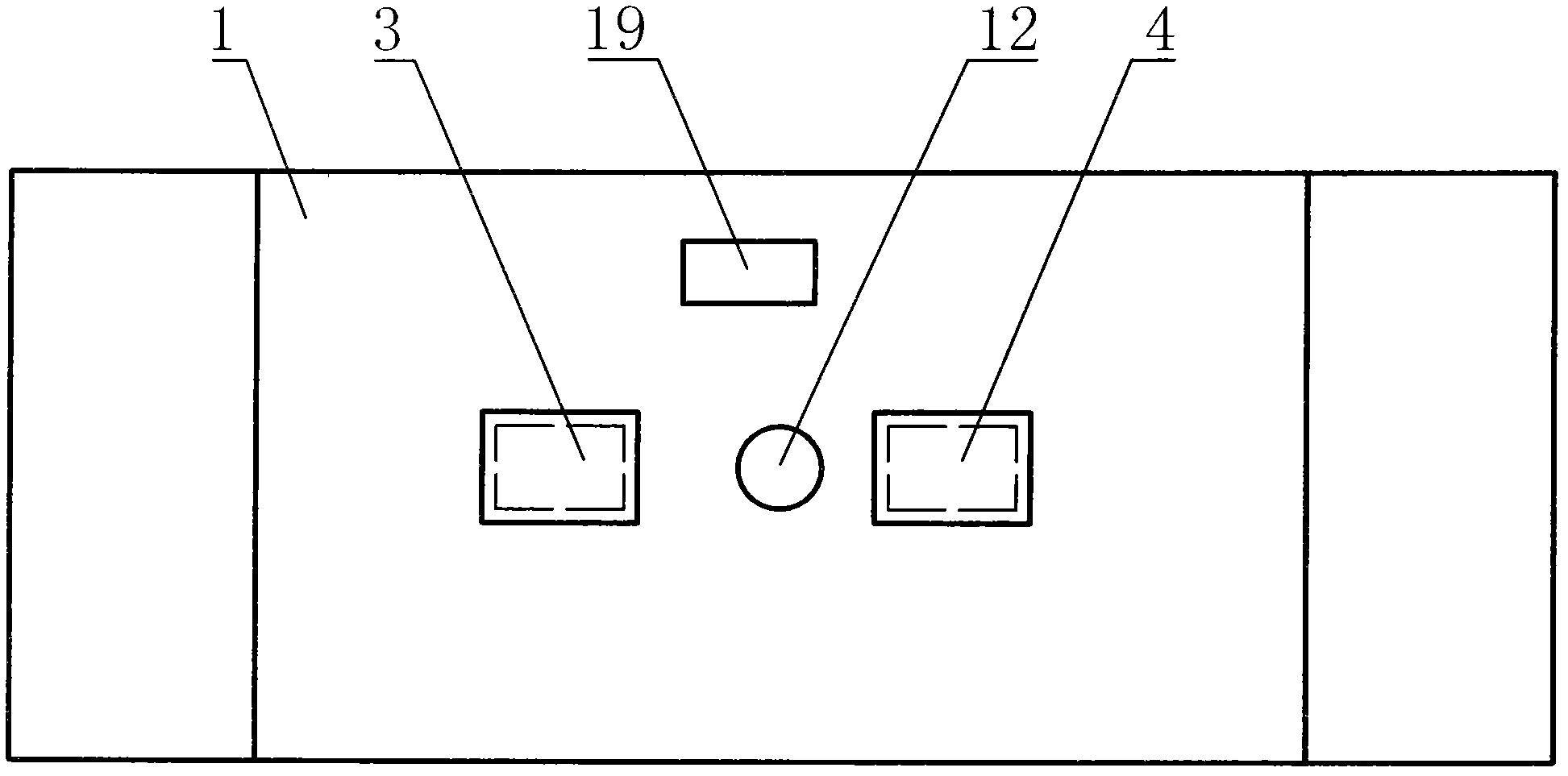

[0024] The air-tight airtight double-drying car flow-through oven of the present invention comprises a box body 1, two drying chambers 2 symmetrically arranged inside the box body 1, a drying car 7 arranged in the drying room 2, and a drying car 7 arranged on the top of the box body 1. The fresh air inlet 3, the dehumidification outlet 4 and the air suction device are arranged in the air outlet chamber 5 between the drying chamber 2, and the air inlet chamber formed between the top of the drying chamber 2 and the side close to the box body 1 and the box body 1 6. The filter 8 arranged on one side of the drying chamber 2 and above the air outlet chamber 5, the air-filled sealing device connected to the drying chamber 2 and communicating with the air outlet chamber 5, and the heater 9 installed in the air inlet chamber 6.

[0025] When using the present invention to carry out the drying operation, the fresh air is sent into the air inlet chamber 6 through the fresh air inlet 3, a...

example 2

[0027] Inflatable and sealed double-drying car flow-through oven of the present invention, such as figure 1 , figure 2 , image 3 As shown, the air suction device includes a motor 12 arranged outside the top of the box body 2, which is sequentially connected to a reducer 11 installed inside the box body 1 below the motor 12 and a fan 10 connected to the moisture discharge outlet 4 at the same time, which can ensure that During the drying operation, the suction work in the box body 1 is carried out normally, and a stable and reliable drying environment is provided at the same time.

[0028] Wherein the drying car 7 comprises a car body 13, a wheel 14 installed at the bottom of the car body 13, an inclined baffle plate 16 arranged at intervals inside the car body 13 and a baking tray 15 provided with some through holes. 16 The drying car 7 with an inclined air duct formed above and below the baking tray 15 can effectively expand the contact area of heat exchange, improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com