Rice hull carbonizing and collecting device

A technology of collecting device and rice husk, which is applied in the field of rice husk carbonization collecting device, can solve the problems of low work efficiency, dust pollution of the working environment, and unclean collection, etc., and achieves the effect of saving work efficiency, high degree of automation and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

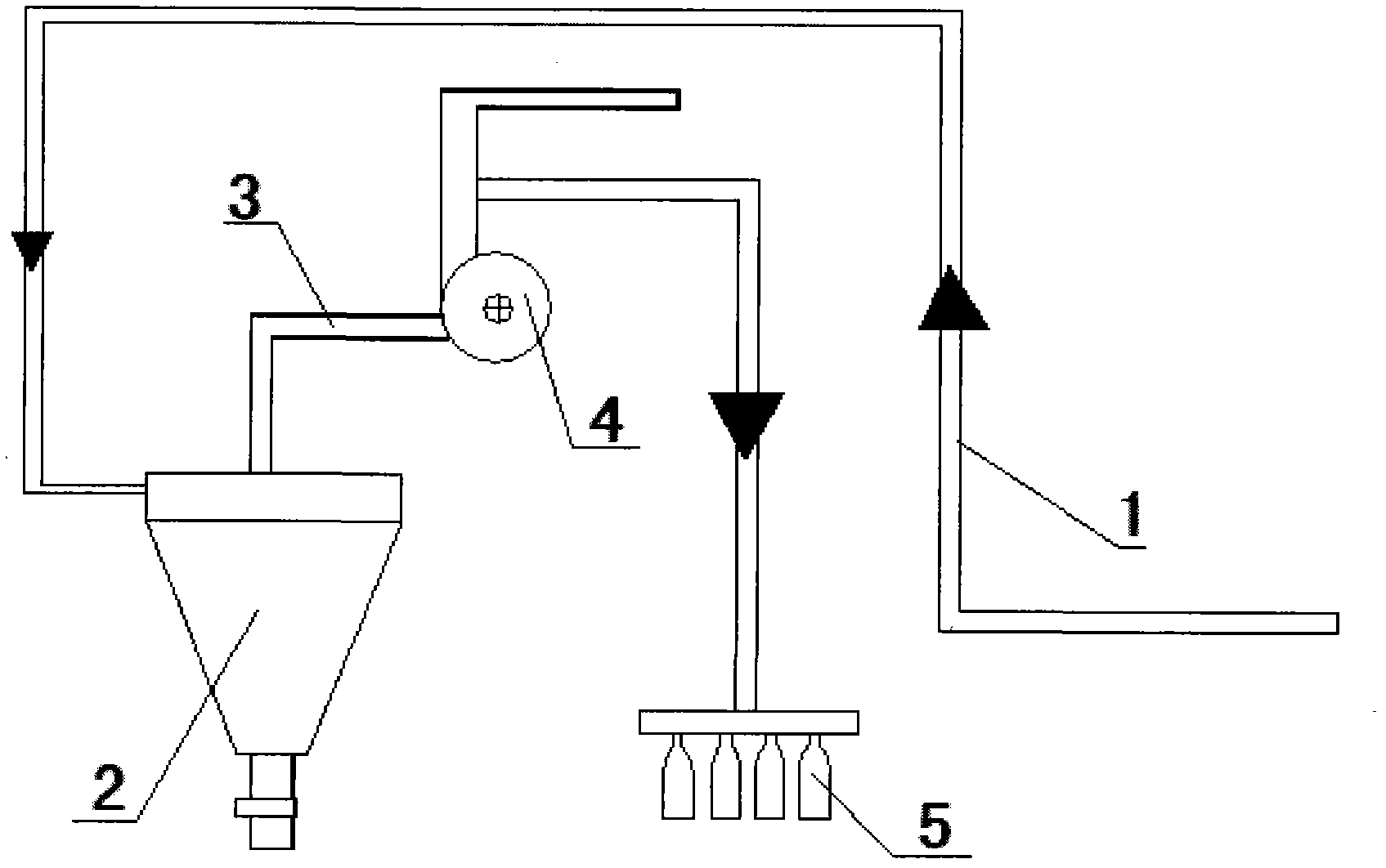

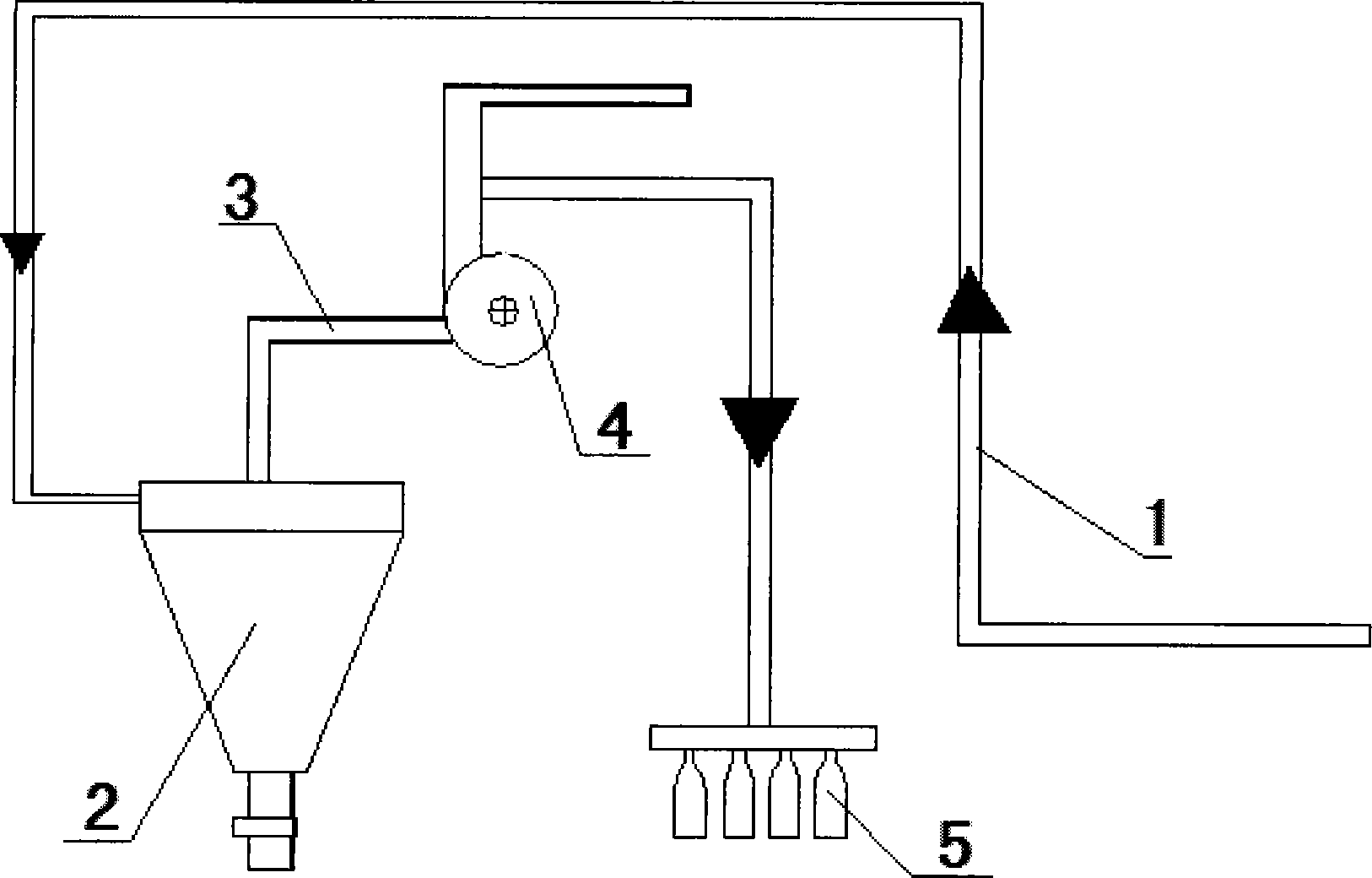

[0012] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Referring to the accompanying drawings, a rice husk carbonization collection device includes an air inlet pipe 1, the air inlet pipe 1 communicates with the top of the fan 2, and the top of the fan 2 communicates with the air inlet of the fan 4 through the air pipe 3, and the fan 4 The air outlet of the air outlet is connected with the bag filter 5 again.

[0014] The working principle of the present invention is:

[0015] The collection port of the intake pipe 1 is at the slag discharge position of the carbonized rice husk boiler; the air inlet of the fan 4 is connected to the fan 3 to absorb the carbonized rice husk; the outlet air of the fan 4 is sent to the bag filter 5; The rice husk is re-burned through secondary transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com