Seawater base fracturing fluid and preparation method thereof

A seawater and base pressure technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in satisfying fracturing construction, and achieve the effects of overcoming damage, good compatibility, and good complexation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

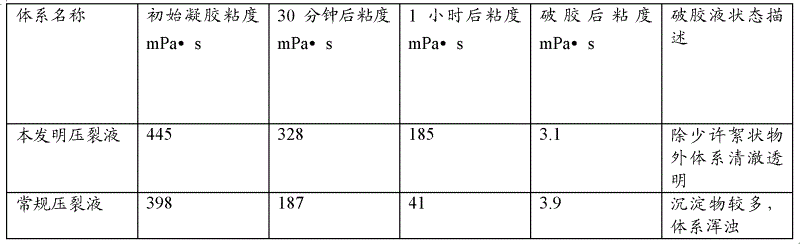

Embodiment 1

[0019] First prepare the thickener: take 50g of guar gum powder and add it to a mixed solution consisting of 100ml of ethanol and 50ml of water, add 3g of sodium hydroxide, control the temperature to 50-55℃, add 60ml of ethylene oxide, and react 3. After hours, cool to room temperature, filter and wash twice, then add to the mixed solution of 100ml isopropanol and 30ml water, add 2.5g sodium hydroxide, control the temperature at 60-65℃, react for 15min, add 5g chloroacetic acid and 1.5g Chlorosulfonic acid is reacted for 4 hours, cooled to room temperature, filtered, washed 3 times, dried and crushed to obtain dry powder to obtain hydroxyethyl carboxymethyl sulfonic acid guar gum.

[0020] Secondly, the preparation of crosslinking agent, add 10.0 g of zirconium oxychloride into 70 g of water, stir to dissolve, and then add 6.8 g of oxalic acid, 2.3 g of monoethanolamine, 4.7 g of triethanolamine, control the temperature at 45-50 ℃, and react for 3 hours to prepare Obtain alkanola...

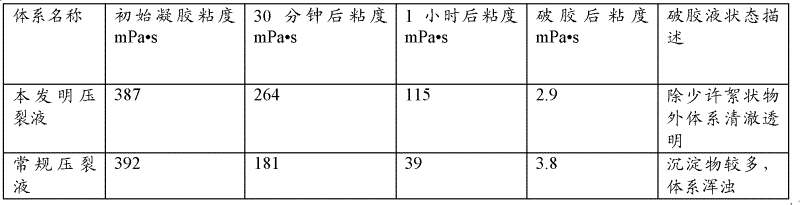

Embodiment 2

[0030] First prepare the thickener: take 50g of guar gum powder and add it to a mixed solution of 100ml of ethanol and 40ml of water, add 4.0g of sodium hydroxide, control the temperature to 50-55℃, add 50ml of ethylene oxide, and react 3 hours, cool to room temperature, filter and wash twice, then add to the mixed solution of 100ml isopropanol and 20ml water, add 2.0g sodium hydroxide, control the temperature at 60-65℃, react for 15min, add 4.0g chloroacetic acid and 2.0 g of chlorosulfonic acid was reacted for 4 hours, cooled to room temperature, filtered, washed 3 times, dried and crushed to make a dry powder to obtain hydroxyethyl carboxymethyl sulfonic acid guar gum.

[0031] Secondly, the preparation of the crosslinking agent, take 9.0 g of zirconium oxychloride, add it to 77 g of water, stir to dissolve, then add 6.8 g of oxalic acid and 7.2 g of triethanolamine in sequence, control the temperature at 50-55°C, and react for 4 hours to obtain triethanolamine zirconic acid E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com