Preparation method of thermoplastic konjac glucomannan/poly butylenes succinate blending material

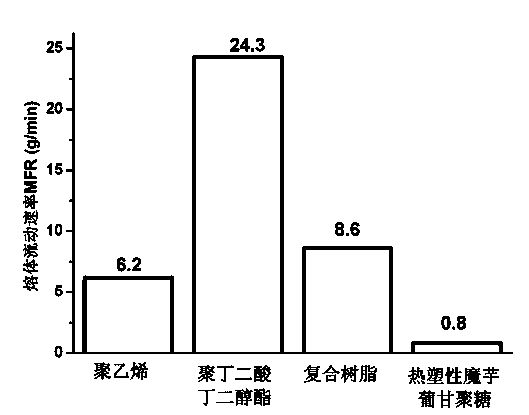

A technology of polybutylene succinate and konjac glucomannan is applied in the field of preparation of thermoplastic konjac glucomannan/polybutylene succinate blend material, which can solve the problem of high price and characteristics of PBS. The problems of low viscosity and high melt index can achieve the effect of low cost, good processing performance and improved processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

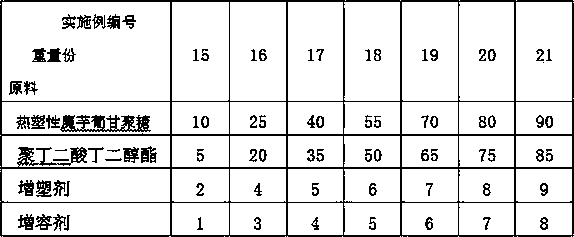

[0025] A preparation method of thermoplastic konjac glucomannan / polybutylene succinate blend material, comprising the following steps:

[0026] Take 80 parts of thermoplastic konjac glucomannan and 20 parts of polybutylene succinate according to the weight ratio, add them to a high-speed mixer and stir for 5 minutes, dry at a temperature of 35°C for 12 hours, and add the above blended materials to the twin-screw In an extruder, melt and blend for 8 minutes at 130°C and 0.5 MPa, extrude, cool, and pelletize to obtain a cylindrical particle blend material with a diameter of 2-3mm and a length of 3-4mm. The prepared blended material is processed into a thermoplastic konjac glucomannan / polybutylene succinate composite film (sheet) through a single-screw extrusion device (screw diameter 20-50mm, aspect ratio 25-40:1) .

Embodiment 2

[0028] A preparation method of thermoplastic konjac glucomannan / polybutylene succinate blend material, comprising the following steps:

[0029] Take 70 parts of thermoplastic konjac glucomannan, 30 parts of polybutylene succinate, 1 part of glycerin, and 6 parts of polycaprolactone according to the weight ratio, add them to a high-speed mixer and stir for 8 minutes, and dry at a temperature of 40 ° C. After 11 hours, put the above blend into a twin-screw extruder, melt and blend for 10 minutes at 140°C and 0.3MPa, extrude, cool, and pelletize to obtain 2-3mm in diameter and 3-4mm in length. Cylindrical particle blend material. The prepared blended material is processed into a konjac glucomannan / polybutylene succinate composite film or plate through a single-screw extrusion device (screw diameter 20-50mm, aspect ratio 25-40:1).

Embodiment 3

[0031] A preparation method of thermoplastic konjac glucomannan / polybutylene succinate blend material, comprising the following steps:

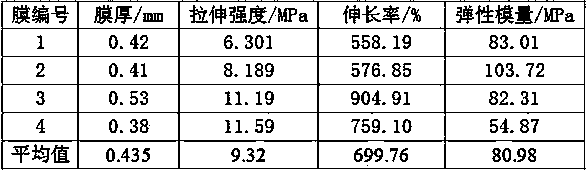

[0032] Take 60 parts of thermoplastic konjac glucomannan by weight, 40 parts of polybutylene succinate, 2 parts of polyethylene glycol, and 10 parts of polycaprolactone, and add them to the high-speed mixer and stir for 10 minutes. Dry at 45°C for 10 hours, put the above blend into a twin-screw extruder, melt and blend at 150°C and 0.6MPa for 12 minutes, extrude, cool and pelletize to obtain a diameter of 2-3mm and a length of 3mm. -4mm cylindrical particle blend material. The prepared blended material is processed into a konjac glucomannan / polybutylene succinate composite film or plate through a single-screw extrusion device (screw diameter 20-50mm, aspect ratio 25-40:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com