High-performance nano-composite material and preparation method thereof

A nano-composite material and high-performance technology, applied in the field of material science, can solve problems such as strong corrosion and irritation, limit the application of composite materials, and side reactions, and achieve the goals of easy operation, development of application value and application range, and improvement of toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

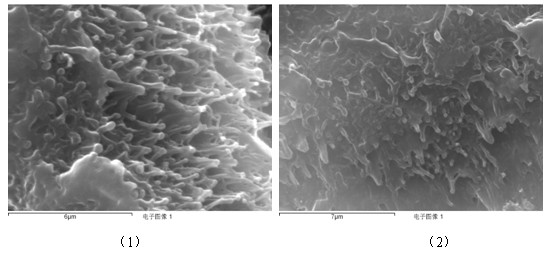

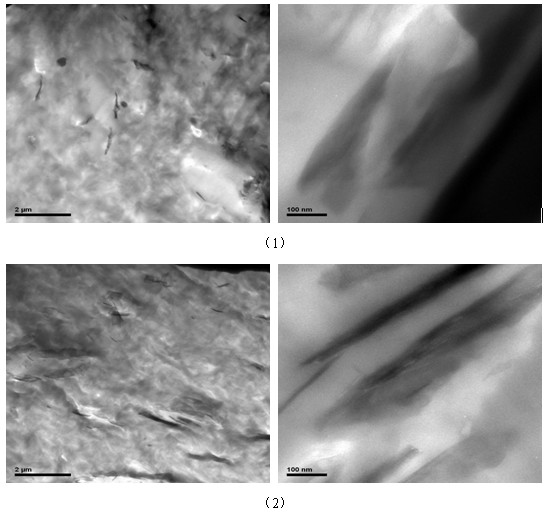

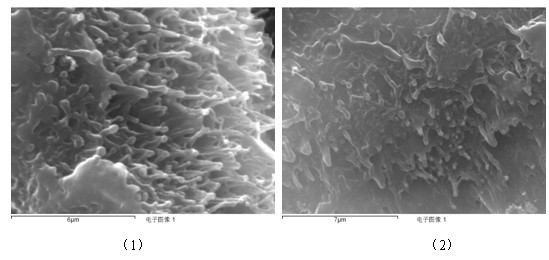

Image

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention: the preparation of high-performance nanocomposite material, calculate by weight, get 100 parts of high-density polyethylene, 2 parts of hydrotalcites and 20 parts of ethylene acrylic acid copolymers standby; Dry in a blast drying oven at 80°C for 16 hours, then fully mix the ethylene acrylic acid copolymer and hydrotalcite in a high-speed mixer for 5 minutes, extrude and granulate through a twin-screw extruder to obtain ethylene acrylic acid / hydrotalcite masterbatches, Then dry the ethylene acrylic acid / hydrotalcite masterbatch at 80°C for 16 hours, mix the dried ethylene acrylic acid / hydrotalcite masterbatch with high-density polyethylene, and extrude through a twin-screw extruder to obtain high-performance high-density polyethylene. Ethylene / hydrotalcite nanocomposite material; during the extrusion process, the screw speed of the twin-screw extruder is 300 rpm, and the extrusion temperature is controlled at 170-205°C.

Embodiment 2

[0025] Embodiment 2 of the present invention: the preparation of high-performance nano-composite material, calculate by weight, get 100 parts of high-density polyethylene, 4 parts of hydrotalcite and 20 parts of ethylene acrylic acid copolymer standby; Dry in a blast drying oven at 80°C for 16 hours, then fully mix the ethylene acrylic acid copolymer and hydrotalcite in a high-speed mixer for 5 minutes, extrude and granulate through a twin-screw extruder to obtain ethylene acrylic acid / hydrotalcite masterbatches, Then dry the ethylene acrylic acid / hydrotalcite masterbatch at 80°C for 16 hours, mix the dried ethylene acrylic acid / hydrotalcite masterbatch with high-density polyethylene, and extrude through a twin-screw extruder to obtain high-performance high-density polyethylene. Ethylene / hydrotalcite nanocomposite material; during the extrusion process, the screw speed of the twin-screw extruder is 300 rpm, and the extrusion temperature is controlled at 170-205°C.

Embodiment 3

[0026] Embodiment 3 of the present invention: the preparation of high-performance nanocomposite material, calculate by weight, get 100 parts of high-density polyethylene, 6 parts of hydrotalcites and 20 parts of ethylene acrylic acid copolymers standby; Dry in a blast drying oven at 80°C for 16 hours, then fully mix the ethylene acrylic acid copolymer and hydrotalcite in a high-speed mixer for 5 minutes, extrude and granulate through a twin-screw extruder to obtain ethylene acrylic acid / hydrotalcite masterbatches, and then Dry the ethylene acrylic acid / hydrotalcite masterbatch at 80°C for 16 hours, mix the dried ethylene acrylic acid / hydrotalcite masterbatch with high-density polyethylene, and extrude through a twin-screw extruder to obtain high-performance high-density polyethylene. Ethylene / hydrotalcite nanocomposite material; during the extrusion process, the screw speed of the twin-screw extruder is 300 rpm, and the extrusion temperature is controlled at 170-205°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com