Tower type photo-thermal power generation system, heliostat, heliostat tracking driving device and heliostat rotating table

A driving device and heliostat technology, which is applied in photovoltaic power generation, solar heating systems, photovoltaic power stations, etc., can solve the problem of low assembly accuracy and rigidity of heliostat tracking drive devices, low assembly accuracy and rigidity of heliostats, and installation accuracy and low rigidity to achieve the effect of ensuring the utilization rate of light and heat, solving the low utilization rate of light and heat, and ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

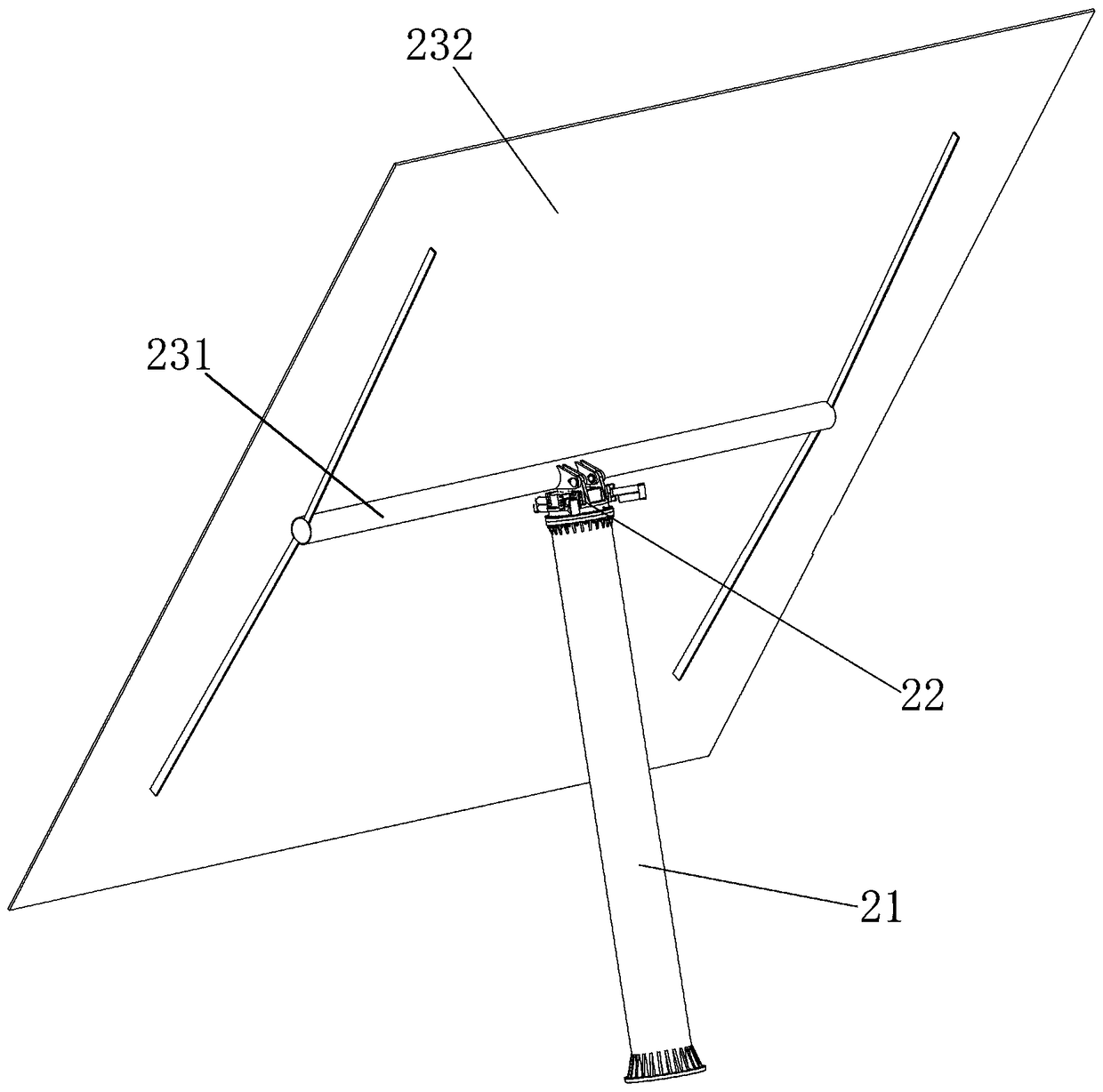

[0038] A specific embodiment of the tower-type photothermal power generation system of the present invention, such as Figure 1 to Figure 8 As shown, the tower photothermal power generation system includes a heat collection tower 1 and a heliostat 2, and the heliostat 2 includes a column 21, a heliostat tracking drive device 22 arranged on the top of the column 21, and a heliostat tracking drive device arranged on the top of the column 21. The reflector 23 on 22, the heliostat tracking drive device 22 includes a fixed base 221 fixedly connected to the column 21, and a turntable 223 is mounted on the fixed base 221 through a bearing 222 for rotation. Specifically, the fixed base 221 includes a ring-shaped bottom plate, and the ring-shaped bottom plate is respectively provided with inner ring screw holes and outer ring screw holes arranged in a ring. , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com