Filamentous sludge bulking recovery method based on non-nitrification A/O (anaerobic/aerobic) biological phosphorus removal process

A technology of sludge bulking and recovery method, which is applied in the direction of aerobic and anaerobic process treatment, can solve the problems of filamentous bacteria sludge bulking, etc., achieve short recovery period, eliminate the symptoms but not the root cause, and solve the problem of filamentous bacteria sludge The effect of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

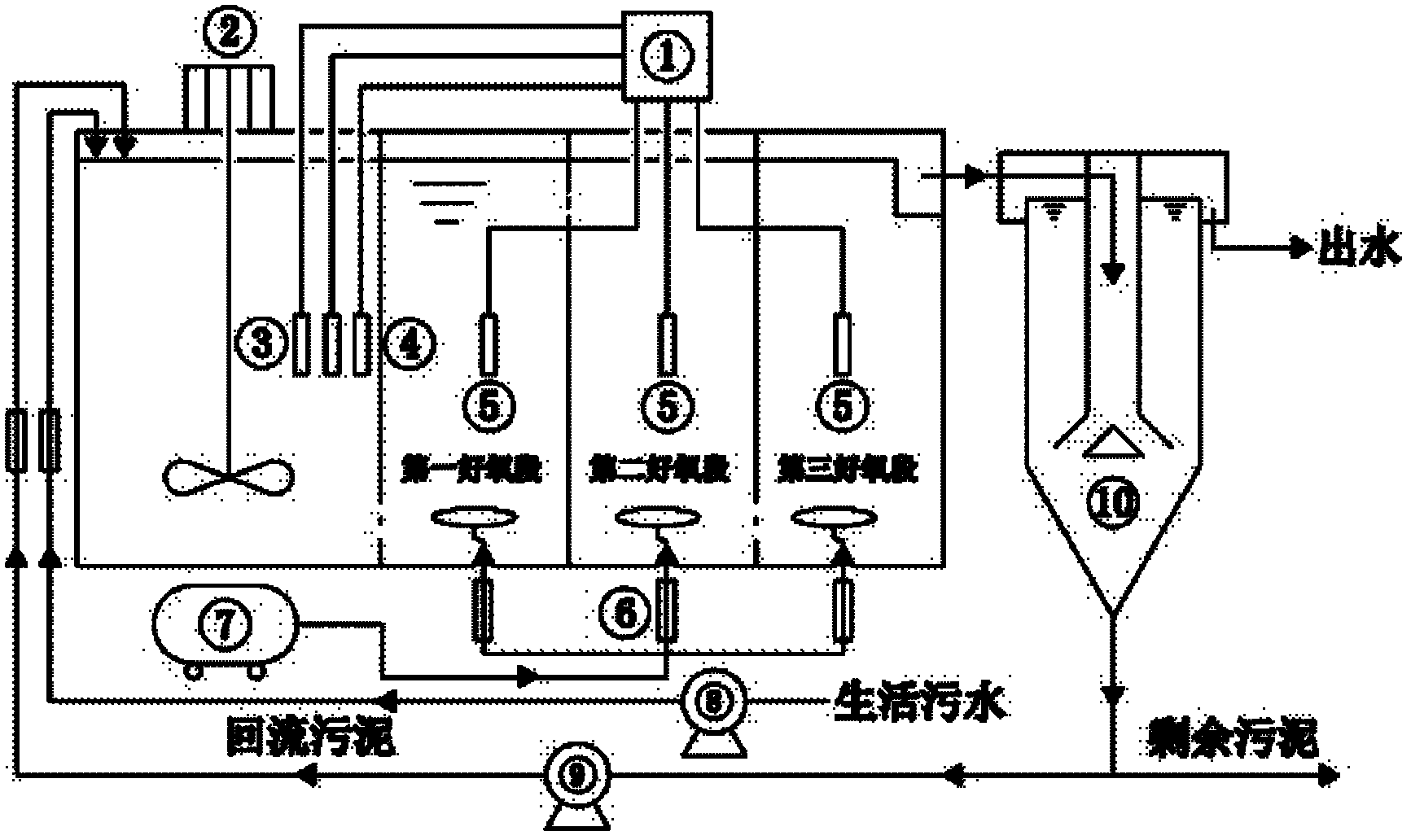

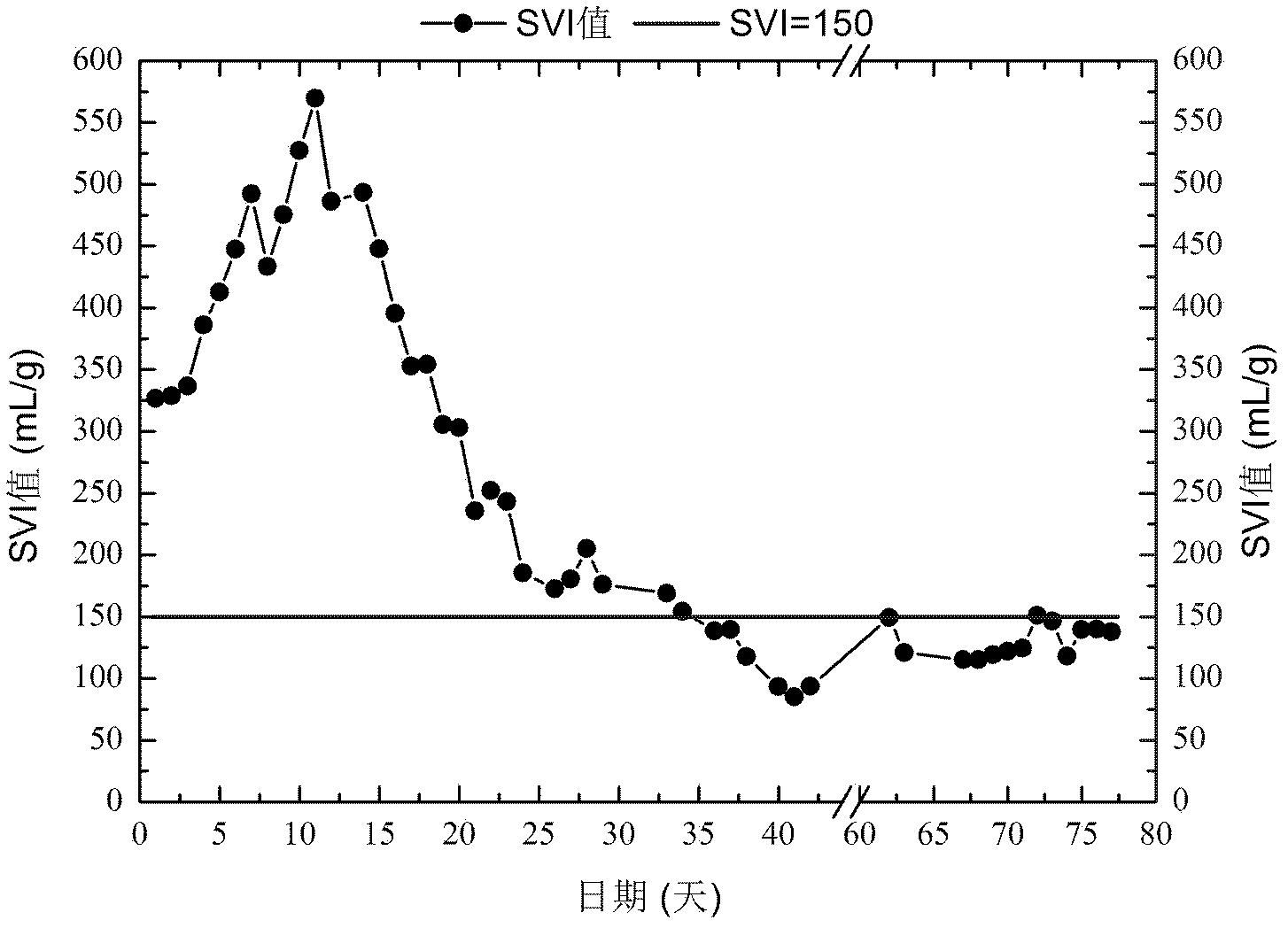

[0028] Example 1 see figure 2 ,

[0029] During the early operation of the system, the aerobic section adopts the aeration method of the perforated aeration tube at the bottom. The indoor air pressure fluctuated greatly, which made it difficult to control the DO of the system, which led to the occurrence of sludge bulking. The SVI reached 326.74mL / g, which was confirmed to be filamentous bacteria sludge bulking by microscope inspection. In addition, the system has been operating at a high level of load (0.7-0.98kgCOD / kgMLSS / d), which made the sludge properties deteriorate for a while, and the SVI value reached 569.8mL / g, which has seriously affected the normal operation of the system.

[0030] Carry out recovery test according to the method described in the present invention. First of all, the equipment has been modified, adding decompression and stabilizing equipment at the main indoor intake pipe, and adding two perforated partitions in the aerobic section to divide the a...

Embodiment 2

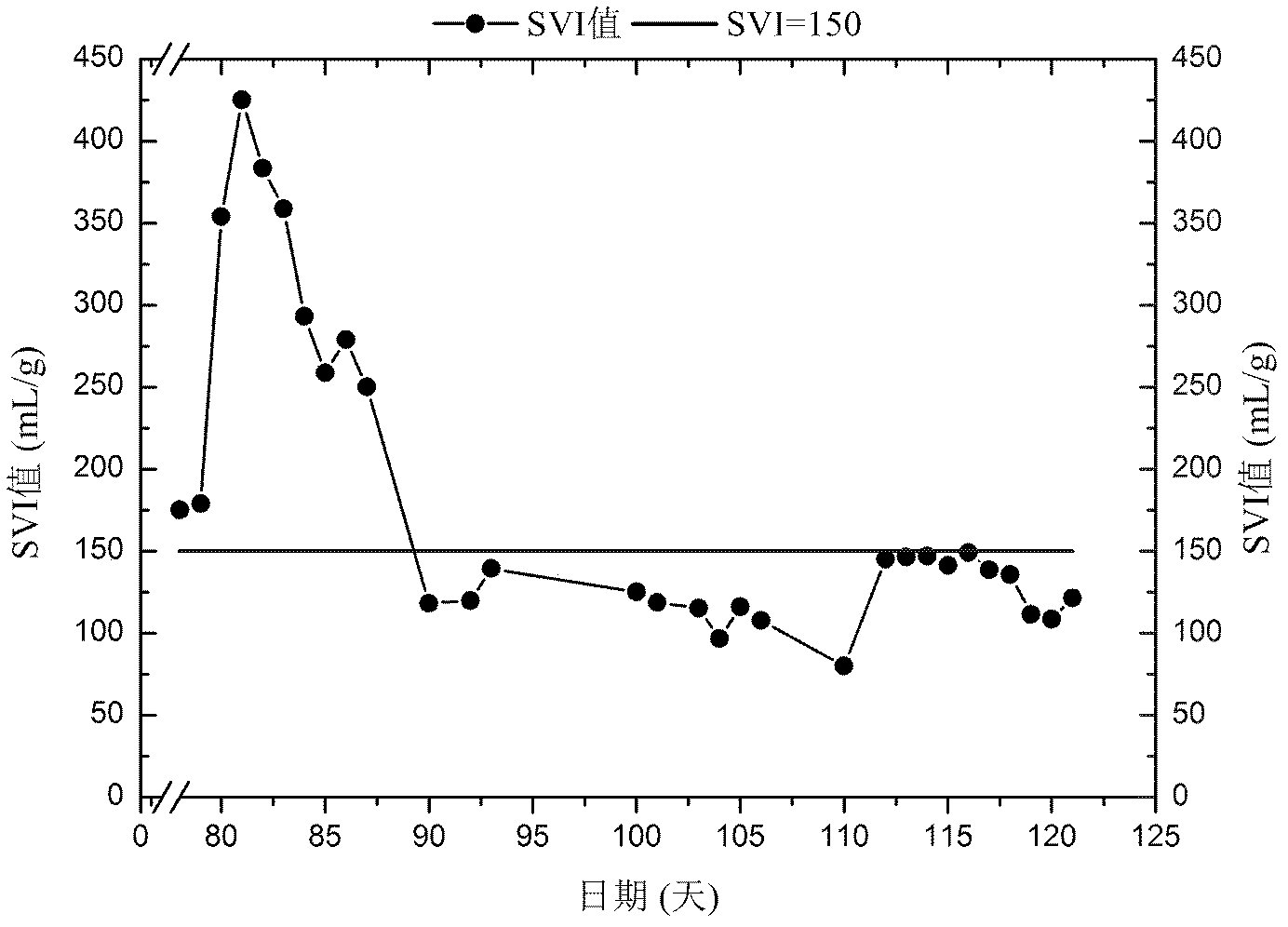

[0033] Example 2 see image 3 ,

[0034] When the reactor operated to the 79th day, the system sludge leaked due to the failure of the return pump, and the reactor sludge lost nearly 60%. The system operates at high load, with a load value as high as 1.54kgCOD / kgMLSS / d, during which DO is controlled at 1.5mg / L. When the system was impacted by high load, the sludge properties deteriorated rapidly in just 3 days, and the SVI once reached 425mL / g.

[0035] Then take regulation and control measure in time, according to operating parameter described in the present invention, by the regulation and control method of step 1, after regulation and control 8 days, SVI value promptly drops to 250mL / g, thinks that the first stage filamentous bacteria is eliminated successfully. Then, according to the control method of step 2, after 10 days of second-stage operation, the system SVI value was basically stable at about 120mL / g on the 100th day, and the sludge properties were good. In the su...

Embodiment 3

[0036] Embodiment 3 see Figure 4 ,

[0037] When filamentous bacteria expansion occurs in the system, take the length, width and height as 0.5 times the original pilot test level (other parameters are exactly the same as the pilot test) to do A / O small test synchronization test verification, and the operating parameters of the small test equipment are the same as the pilot test.

[0038] According to the operating parameters of the present invention, according to the control method of step 1, after 13 days of control, the SVI value dropped to 227.3mL / g, and it was considered that the first stage of filamentous bacteria was successfully eliminated. Afterwards, according to the control method of step 2, after 10 days of second-stage operation, the system SVI value was basically stable at about 120mL / g on the 50th day, and the sludge properties were good. In the subsequent operation, there has been no sludge bulking The phenomenon. From Figure 4 It can be seen that the SVI v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com