Method for preparing molecular sieve by using Hangjin 2# soil as raw material and prepared molecular sieve

A molecular sieve and raw material technology, applied in the field of preparation methods and molecular sieves prepared by the method, can solve problems such as insufficient technology, and achieve the effects of saving industrial-grade raw materials, good effect and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1. Mix Hangjin 2# soil and sodium hydroxide at a weight ratio of 1:1.2, and then roast at a constant temperature of 550°C for 90 minutes after mixing, and mix the obtained roasted product with water at a liquid-solid mass ratio of 5:1. The resulting mixed solution was continuously stirred at 70° C. at a speed of 300 rpm for 4 hours, then filtered, and aluminum sulfate solution was added to the filtrate to adjust the molar ratio of silicon-aluminum atoms in the filtrate to 5.0, and then at room temperature at 300 rpm. Stir continuously at high speed for 30 minutes, then crystallize at 130°C for 5 hours, then cool the crystallized product, filter, wash with water until the pH is 10, and dry at 110°C, the purity of the obtained P-type zeolite molecular sieve is 95.2% , and the output rate was 54.8%.

Embodiment 2

[0036] Example 2. Mix Hangjin 2# soil and sodium hydroxide at a weight ratio of 1:1.3, and then roast at a constant temperature of 600°C for 90 minutes after mixing, and mix the obtained roasted product with water at a liquid-solid mass ratio of 5:1. The resulting mixture was continuously stirred at 80°C at a speed of 300 rpm for 4 hours, then filtered, and aluminum sulfate solution was added to the filtrate to adjust the molar ratio of silicon to aluminum atoms in the filtrate to 6.0, and then at room temperature at 300 rpm Stir continuously at high speed for 30 minutes, then crystallize at 140°C for 5 hours, then cool the crystallized product, filter, wash with water until the pH is 10, and dry at 110°C. The purity of the obtained P-type zeolite molecular sieve is 96.3% , and the output rate was 54.5%.

Embodiment 3

[0037]Example 3. Mix Hangjin 2# soil and sodium hydroxide at a weight ratio of 1:1, and then roast at a constant temperature of 500°C for 90 minutes after mixing, and mix the obtained roasted product with water at a liquid-solid mass ratio of 5:1. The resulting mixture was continuously stirred at 60° C. at a speed of 300 rpm for 4 hours, then filtered, and aluminum sulfate solution was added to the filtrate to adjust the molar ratio of the silicon-aluminum atoms in the filtrate to 4.0, and then at room temperature at 300 rpm. Stir continuously at high speed for 30 minutes, then crystallize at 120°C for 4 hours, then cool the crystallized product, filter, wash with water until the pH is 10, and dry at 110°C, the purity of the P-type zeolite molecular sieve obtained is 94.2% , and the output rate was 56.7%.

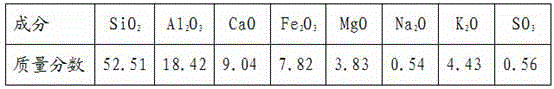

[0038] Only list the SiO in the selected Hangjin 2# soil in the embodiment 4~7 2 content, and the content of other ingredients is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com